3

Setting the motor end switch:

Attention: The built-in motor has a set end

stop both in the extension and retraction direction.

These settings were effected in the factory. They

always have to be checked on site, as the end stops

might have shifted e.g. through strong vibrations

during transport or the motor does not switch off

anymore. For any changes or corrections of these

settings please refer to the instructions of the

motor.

The installation and setting instructions are indi-

cated on the motor's power supply cable. When set-

ting remote-controlled motors, kindly start at point

"factory"-programming of the instruction manual!

Attention: The rolling up of the fabric on the

fabric roller from top during retraction could result

in damage to the awning fabric and the awning

frame. When setting the end positions of the motor

it is important to ensure that the fabric winds up as

shown during the retraction process:

Sense of rotation of the fabric roller during the

retraction process:

Correct! Wrong!

1 = fabric roller

2 = fabric

When the awning is extended, at least half a turn of

the fabric has to remain on the fabric roller as secu-

rity! Never set the end position of the motor in such

a way that the fabric unwinds completely.

We cannot assume any responsibility for damages

resulting from wrong settings.

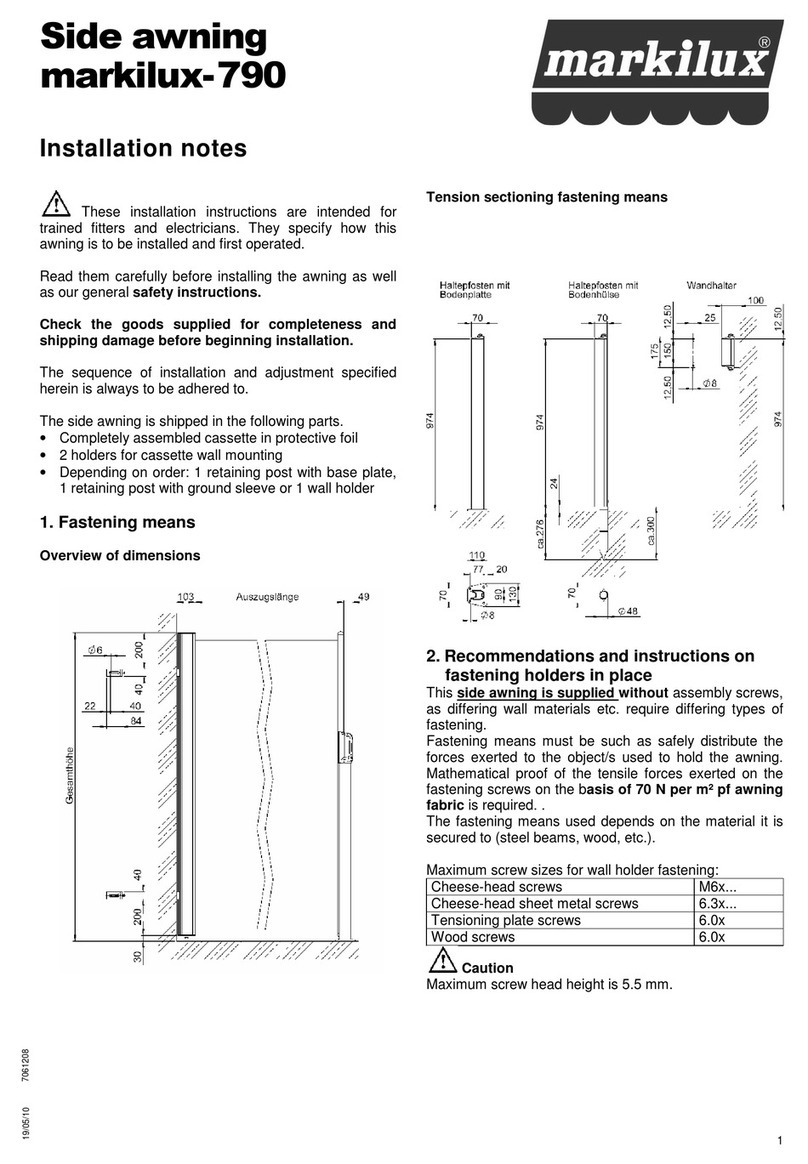

4. Mounting / suspension of awning (single

unit)

4.1 Remove protective cover and check individual

parts.

4.2 Mark the position of the brackets on the

mounting surface, mark drilling holes and drill

(see examples for mounting).

For 2 brackets: each time outside with a clear-

ance of at least 5 cm and max. 20 cm to the

outer edges of the cassette awning.

For 3 brackets (from 326 cm awning width): 2

brackets each time outside with a clearance of

at least 5 cm and max. 20 cm to the outer

edges of the cassette awning, 3 brackets cen-

tered.

The mounting of additional consoles is possi-

ble.

4.3 Mount the brackets horizontally on the mount-

ing surface. The brackets have to be flush to

each other (cord pulley)

.

4.4 For units with interior operation:

Mark drillings for drive pin and console on the

drive side according to the supplied template

and drill hole.

Attention: The inside laying is pivoted for

tension-free connection with the drive rod.

Adjustment range to the horizontal line:

about 0° downwards

about 30° upwards

4.5 Suspend cassette into the brackets, put in the

requested position and tighten the locking

screws SW 10.

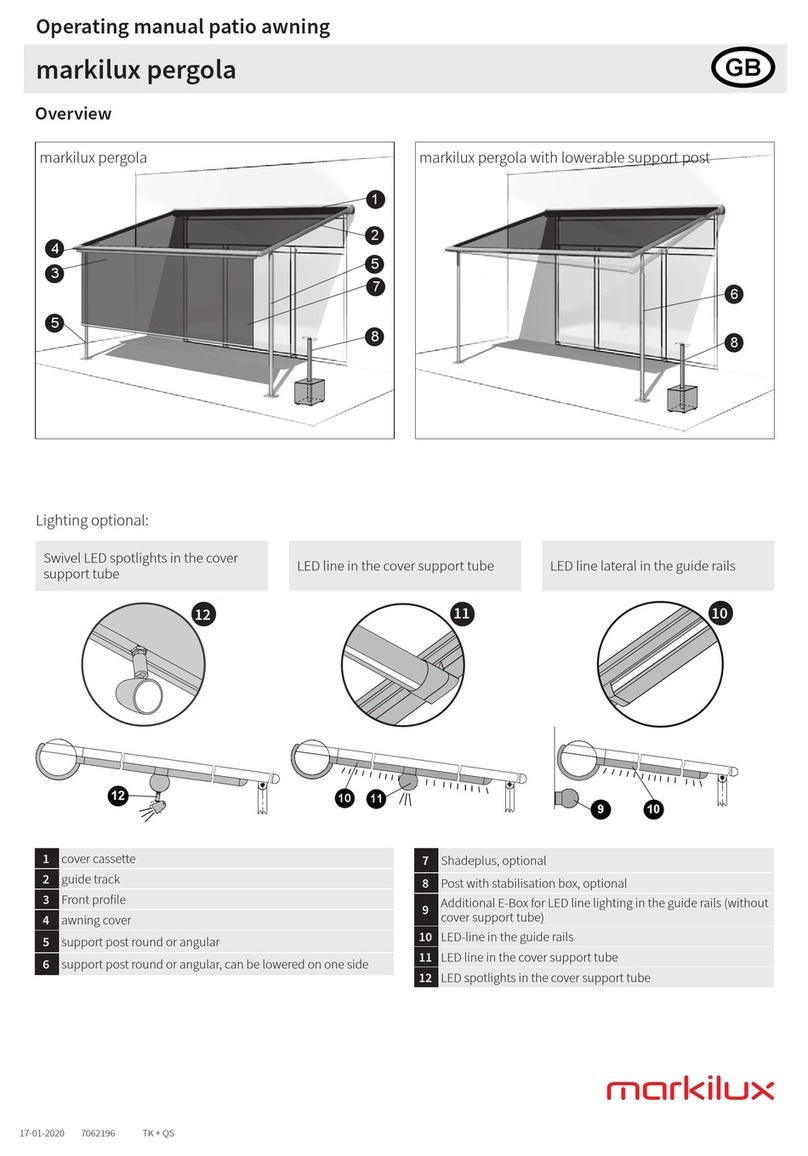

4.6 Mark the lower floor brackets of the accesso-

ries for tension ropes on the mounting surface,

mark drillings, drill and screw.

Measure floor angle parallel and diagonal.

4.7 Mount tensioning device for rope guide with

the hexagon screw M6x16 and the hexagon

screw M 6x12 with serrated lock washer A6, do

not tighten screws.

Attention: Mount serrated lock washer

between tensioning device and floor angle.

4.8 Guide the pre-mounted ropes from top through

the holes of the downpipe end caps at the pro-

jection profile.

4.9 Guide the wire rope through the drillings of the

rope tensioning device and fix by tightening

1

2

projection profile

downpipe end cap

floor angle

hexagon screw

M6x16, SW10

tensioning device for

rope guide, SW13

serrated lock washer

A6