© 2018 nVent 89087984

- 2 -

NOTE: Please read this manual carefully before installing the unit. This user manual is an

integral part of the product and should accompany it until it is eventually disassembled.

TABLE OF CONTENTS

HOW TO CONSULT THIS MANUAL ........................................................................................................................................................... 2

THIS MANUAL IS INTENDED FOR THE FOLLOWING:............................................................................................................................................... 3

PURPOSE OF THE INFORMATION CONTAINED IN THIS MANUAL:........................................................................................................................ 3

RESTRICTIONS TO THE USE OF THIS MANUAL....................................................................................................................................................... 3

WHERE AND HOW TO STORE THIS MANUAL........................................................................................................................................................... 3

CURRENT TECHNOLOGY ............................................................................................................................................................................................ 3

UPDATES ...................................................................................................................................................................................................................... 3

IN THE EVENT OF SALE OF THE PRODUCT .............................................................................................................................................................. 3

UNPACKING AND INSPECTION................................................................................................................................................................. 4

Included in the carton:................................................................................................................................................................................................. 4

UNIT IDENTIFICATION................................................................................................................................................................................................. 4

SAFETY REMARKS ..................................................................................................................................................................................... 5

PRECAUTIONS WHEN HANDLING THE UNIT ........................................................................................................................................................... 5

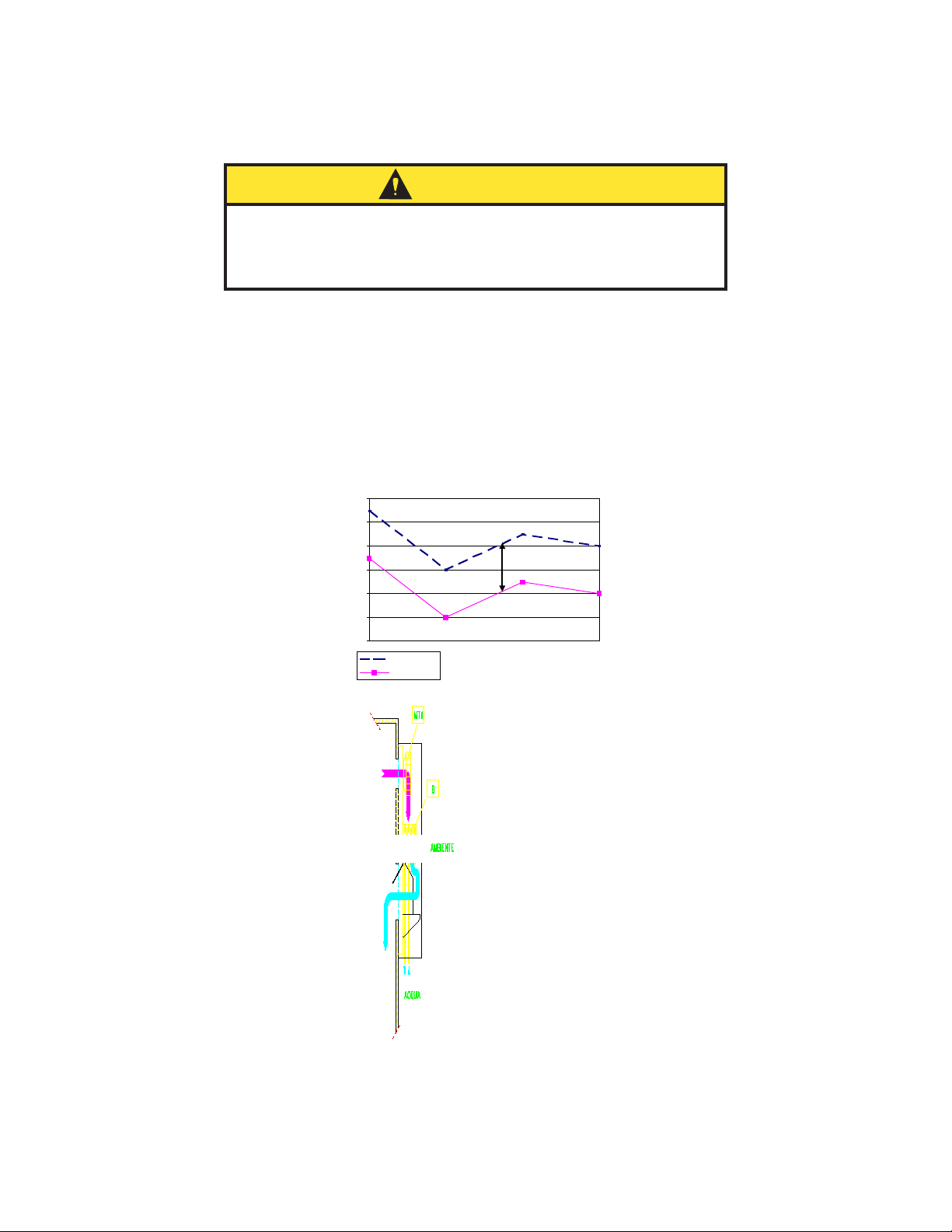

OPERATING PRINCIPLE ............................................................................................................................................................................. 6

COOLING CAPACITY.................................................................................................................................................................................................... 7

Performance Data WCHE019 Series.......................................................................................................................................................................... 7

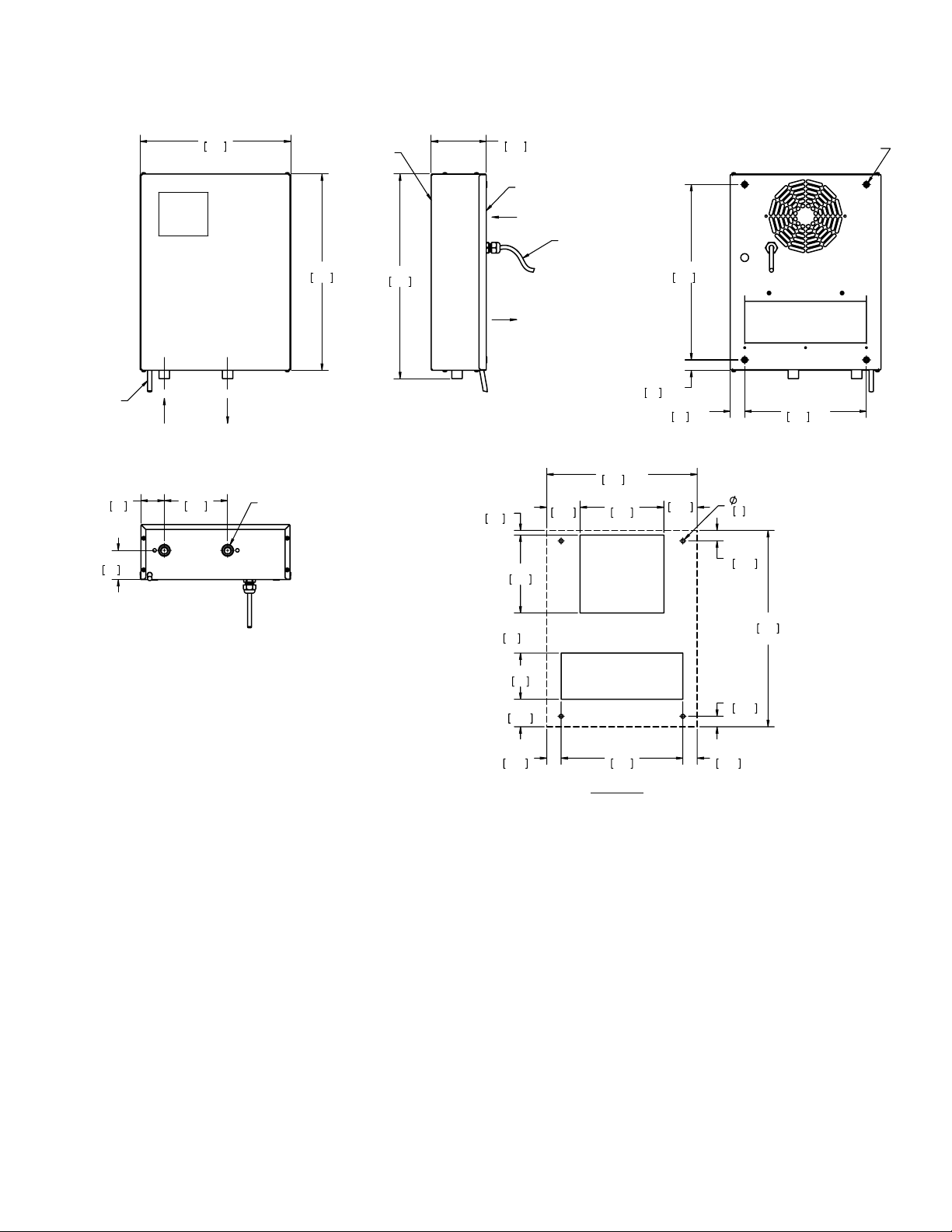

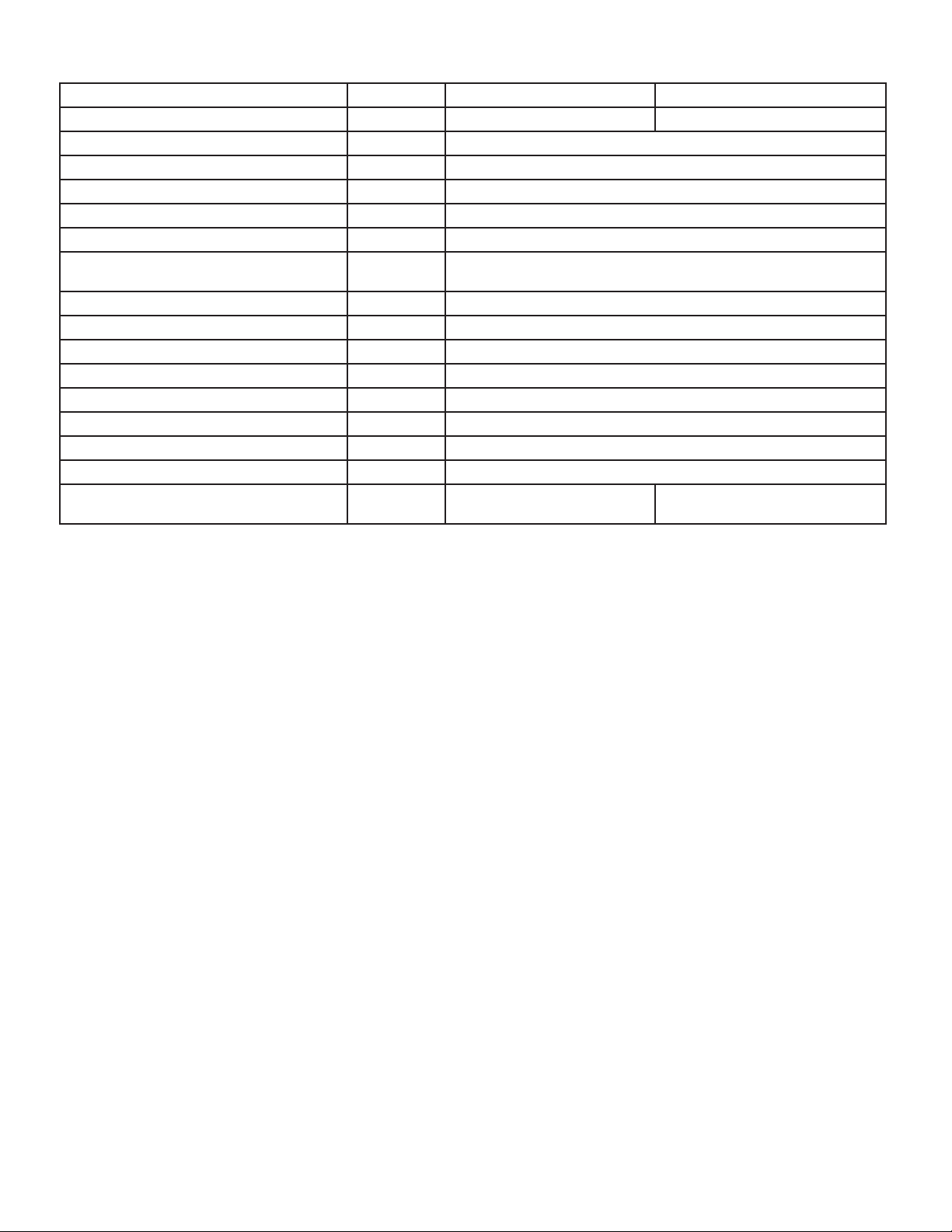

Design Data WCHE019 Series................................................................................................................................................................... 8

Performance Data WCHE049 Series.......................................................................................................................................................................... 9

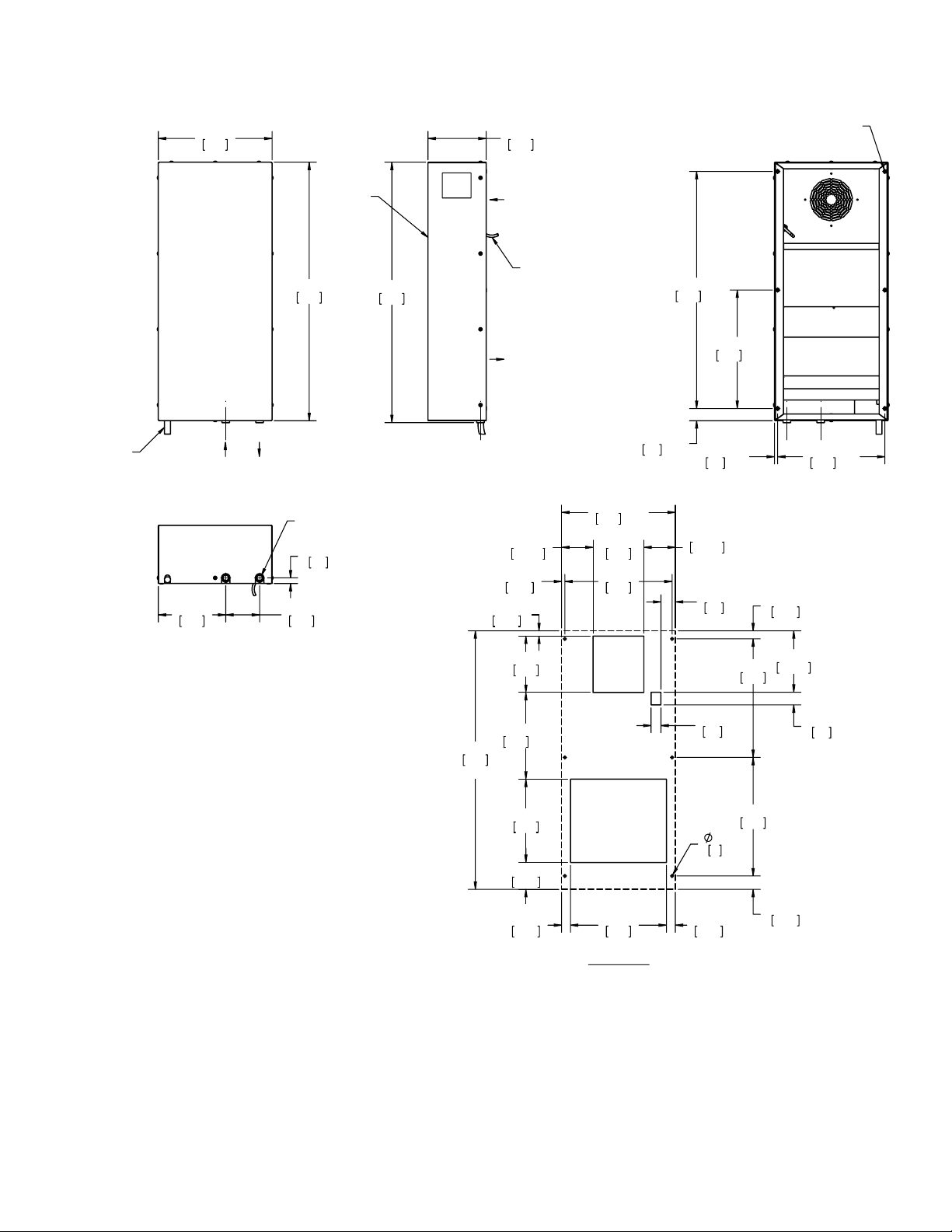

Design Data WCHE049 Series.................................................................................................................................................................10

Performance Data WCHE069 Series........................................................................................................................................................................ 11

Design Data WCHE069 Series.................................................................................................................................................................12

Performance Data WCHE149 Series........................................................................................................................................................................ 13

Design Data WCHE149 Series.................................................................................................................................................................14

INSTALLATION INSTRUCTIONS..............................................................................................................................................................15

Installation.................................................................................................................................................................................................................. 15

WATER CONNECTIONS.............................................................................................................................................................................................16

MECHANICAL PARTS...............................................................................................................................................................................18

STRUCTURE................................................................................................................................................................................................................18

HEAT EXCHANGE BANK ...........................................................................................................................................................................................18

CONDENSATE COLLECTION BASIN.........................................................................................................................................................................18

FLOW CONTROL SOLENOID VALVE.........................................................................................................................................................................18

MOTORS .................................................................................................................................................................................................... 19

FANS............................................................................................................................................................................................................................ 19

CONTROL, MONITORING AND SAFETY COMPONENTS ......................................................................................................................19

REGULATING THERMOSTAT FOR SOLENOID VALVE.............................................................................................................................................19

Adjustments.......................................................................................................................................................................................... 19

ELECTRICAL CONNECTIONS ..................................................................................................................................................................20

WCHE019 only ........................................................................................................................................................................................................... 20

WCHE049, WCHE069, WCHE149 ............................................................................................................................................................................. 21

START-UP................................................................................................................................................................................................... 21

TEMPERATURE CONTROL.......................................................................................................................................................................21

PRELIMINARY CHECKS AFTER STARTING THE UNIT ..........................................................................................................................21

TURNING OFF THE UNIT.......................................................................................................................................................................... 21

MAINTENANCE......................................................................................................................................................................................... 22

PREVENTATIVE MAINTENANCE SCHEDULE..........................................................................................................................................................22

Twice a year .......................................................................................................................................................................................... 22

Annually................................................................................................................................................................................................. 22

REPLACEMENT OF COMPONENTS.................................................................................................................................................... 22

HOW TO CLEAN THE UNIT .................................................................................................................................................................. 22

INACTIVITY ........................................................................................................................................................................................... 22

INFORMATION ON RESIDUAL HAZARDS AND EMERGENCY SITUATIONS ........................................................................................23

GENERAL SAFETY PROVISIONS ......................................................................................................................................................... 23

HAZARDS ARISING FROM THE PRODUCT COMING INTO CONTACT WITH THINGS OR PERSONS.................................................................23

SAFETY STANDARDS FOR ELECTRICAL EQUIPMENT...........................................................................................................................................23

Introduction........................................................................................................................................................................................... 23

TASKS ASSIGNED TO OFFICERS-IN-CHARGE.........................................................................................................................................................23

HIGH VOLTAGE...........................................................................................................................................................................................................23

SAFETY STANDARDS TO COMPLY WITH WHEN THE EQUIPMENT IS TURNED OFF .........................................................................................24

SAFETY STANDARDS TO COMPLY WITH WHEN SERVICING LIVE EQUIPMENT ................................................................................................24

SAFETY STANDARDS TO COMPLY WITH WHEN SERVICING THE UNIT..............................................................................................................24

FIRE HAZARDS...........................................................................................................................................................................................................24

TOXIC SUBSTANCES .................................................................................................................................................................................................24

DANGERS ARISING FROM FLUIDS........................................................................................................................................................................... 24

DISASSEMBLING THE UNIT.....................................................................................................................................................................25

TROUBLE SHOOTING ...............................................................................................................................................................................26

Symptoms and Possible Causes:............................................................................................................................................................................. 26

Replacement Parts .................................................................................................................................................................................................... 27

WARRANTY ............................................................................................................................................................................................... 30

RETURN AND REPAIR POLICY.................................................................................................................................................................................. 30

LIMITATION OF LIABILITY......................................................................................................................................................................................... 31