4

Recommended cleaving tension..................................................................................................................................... 26

General ....................................................................................................................................................................... 26

Blade intrusion............................................................................................................................................................ 26

Hackle ......................................................................................................................................................................... 26

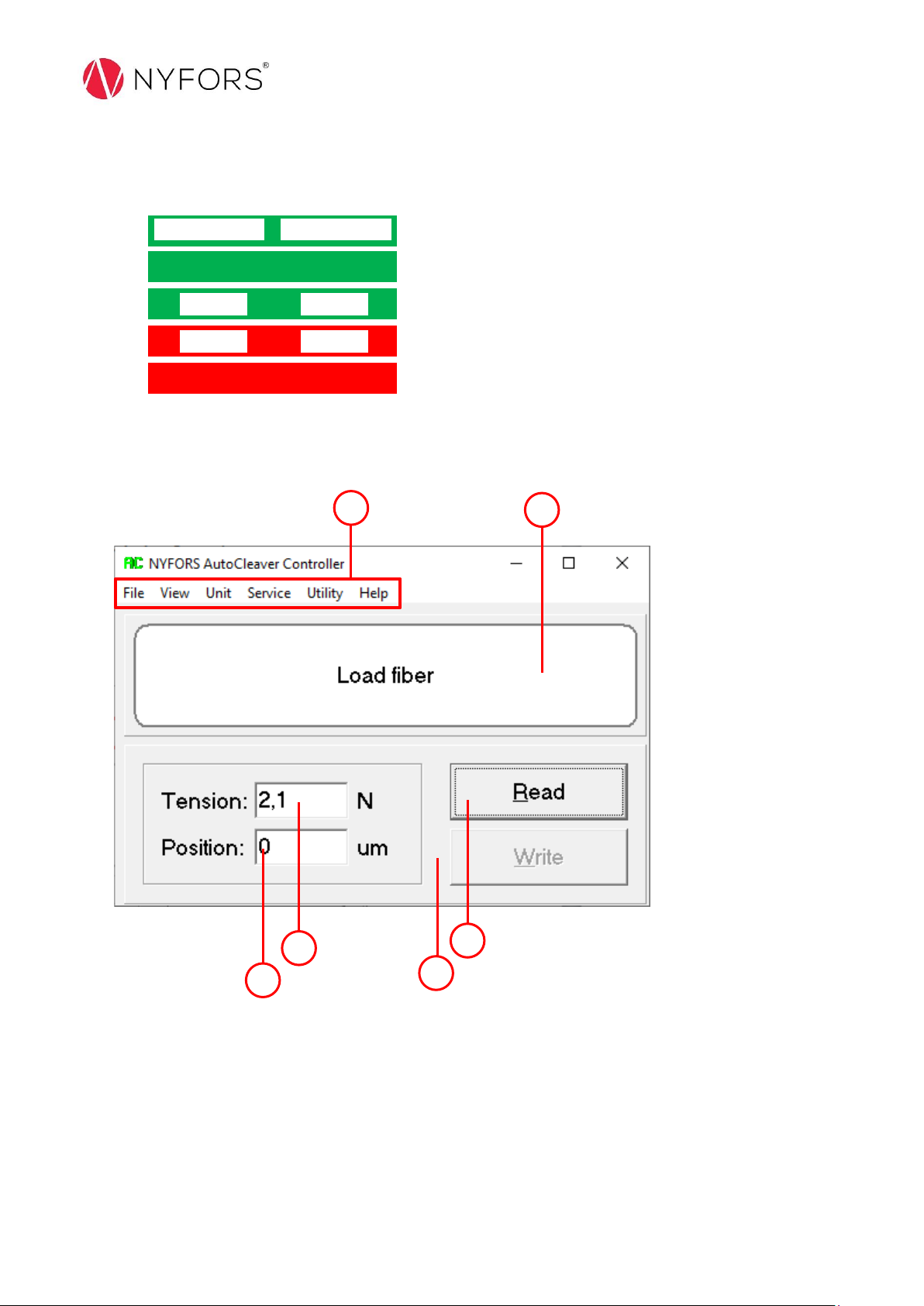

AUTOCLEAVER Controller Software.................................................................................................................................... 27

Using the application ...................................................................................................................................................... 27

Start-up....................................................................................................................................................................... 27

Select COM port.......................................................................................................................................................... 27

Changing the cleaving tension .................................................................................................................................... 28

Adjusting the cleave length ........................................................................................................................................ 28

Complete control description............................................................................................................................................. 29

Main view ....................................................................................................................................................................... 29

File menu ........................................................................................................................................................................ 29

View menu...................................................................................................................................................................... 29

Unit menu ....................................................................................................................................................................... 29

Service menu .................................................................................................................................................................. 29

Utility menu .................................................................................................................................................................... 30

Help menu ...................................................................................................................................................................... 30

Cleaver setup ...................................................................................................................................................................... 30

Setup window ................................................................................................................................................................. 30

Installation of fiber handling parts ..................................................................................................................................... 32

Installation of the adaptor plate..................................................................................................................................... 32

Fujikura FH-100 adaptor ................................................................................................................................................. 33

FITEL S710S adaptor........................................................................................................................................................ 34

Adjusting the cleave length mechanically....................................................................................................................... 34

Installation of the v-groove and height adjustor ................................................................................................................ 35

Definitions........................................................................................................................................................................... 36

Maintenance & Service....................................................................................................................................................... 37

Inspection & Cleaning......................................................................................................................................................... 37

General cleaning ............................................................................................................................................................. 37

Cleaning the v-groove & fixed clamp block .................................................................................................................... 38

Cleaning the v-groove and height adjuster ramp ........................................................................................................... 38

Emptying the fiber waste collector..................................................................................................................................... 38

Cleaver blade ...................................................................................................................................................................... 39

Cleaning the cleaver blade.............................................................................................................................................. 39

Changing cleaver blade position..................................................................................................................................... 39

Replacing the cleaver blade............................................................................................................................................ 39

Verifying & calibrating the load cell.................................................................................................................................... 39

Appendix A.......................................................................................................................................................................... 40

Specifications.................................................................................................................................................................. 40