Struers Discotom-60 User manual

Discotom-60/-65

Instruction Manual

Manual No.: 15907001

Date of Release: 09.09.2013

Discotom-60 /-65

Instruction Manual

Table of Contents Page

User’s Guide.............................................................................1

Reference Guide.....................................................................35

Quick Reference Guide...........................................................61

Always state

Serial No and Voltage/frequency if you have technical questions or when ordering spare parts.

You will find the Serial No. and Voltage on the type plate of the machine itself. We may also need the

Date

and

Article No of the manual. This information is found on the front cover.

The following restrictions should be observed, as violation of the restrictions may cause cancellation of

Struers legal obligations:

Instruction Manuals:

Struers Instruction Manuals may only be used in connection with Struers equipment

covered by the Instruction Manual.

Service Manuals:

Struers Service Manuals may only be used by a trained technician authorised by Struers.

The Service Manual may only be used in connection with Struers equi

pment covered by the Service Manual.

Struers assumes no responsibility for errors in the manual text/illustrations. The information in this manual is

subject to change without notice. The manual may mention accessories or parts not included in the present

version of the equipment.

Original instructions.

The contents of this manual are the property of Struers. Reproduction of any part of

this manual without the written permission of Struers is not allowed.

All rights reserved. © Struers

2013.

Struers A/S

Pederstrupvej 84

DK

-2750 Ballerup

Denmark

Telephone +45 44 600 800

Fax +45 44 600 801

Discotom-60 /-65

Instruction Manual

Discotom-60/ -65

Safety Precaution Sheet

To be read carefully, before use

1. The operator(s) should be fully instructed in the use of the machine and

its cut-off wheels according to the Instruction Manual and the

instructions for the use of cut-off wheels.

2. The machine must be installed in compliance with local safety

regulations.

3. The machine must be placed on a safe and stable support table. All

safety functions and guards of the machine must be in working order.

4. Use only intact cut-off wheels. The cut-off wheels must be approved for

use with rotational speeds between 1000 and 3460 rpm.

5. The machine is not for use with saw-blade type cut-off wheels.

6. Observe the current safety regulations for handling, mixing, filling,

emptying and disposal of the additive for cooling fluid.

7. The workpiece must be securely fixed in the quick-clamping device or

similar. Large or sharp workpieces must be handled in a safe way.

8. Do not work on or around cutting table when the table is repositioned

using the Y-table positioning joystick.

9. To achieve maximum safety and lifetime of the machine, use only

original Struers consumables.

10. The cutting handle should be lowered slowly and carefully, in order to

avoid breaking the cut-off wheel.

Discotom-60 /-65

Instruction Manual

11. Struers recommends the use of an exhaust system as the materials

being cut may emit harmful gasses or dust.

12. The machine emits only moderate noise. However, the cutting process

itself may emit noise, depending on the nature of the workpiece. In

such cases, the use of hearing protection is recommended.

13. The machine must be disconnected from the mains prior to any service.

14. Use of working gloves is recommended as workpieces may be both

very hot and produce sharp edges. Wearing of gloves is also

recommended when flushing and cleaning the machine.

15. Struers recommends the use of safety shoes when working with heavy

samples.

16. Use of safety goggles is recommended when using the flushing hose.

17. If any of the cutting-chamber hood springs are damaged (at the rear of

machine), they must be replaced before the machine is used again.

18. When a recirculation cooling unit is used, observe the current safety

regulations for handling, mixing, filling, emptying and disposal of the

additive for cooling fluid.

Do not use flammable cooling fluid.

19. When lifting the machine using a forklift, lift from front or rear - never lift

the machine from the side.

20. When lifting the machine using lifting straps, ensure that the straps are

crossed and do not press on the sides of the machine.

1. Prior to any service, disconnect the machine then wait until residual

potential on the capacitors is discharged.

2. Do not cycle mains power more than once every three minutes.

Damage to the frequency converter will result.

Discotom-65

The equipment should only be used for its intended purpose and as detailed in the Instruction Manual.

The equipment is designed for use with consumables supplied by Struers. If subjected to misuse, improper

installation, alteration, neglect, accident or improper repair, Struers will accept no responsibility for

damage(s) to the user or the equipment.

Dismantling of any part of the equipment, during service or repair, should always be performed by a qualified

technician (electromechanical, electronic, mechanical, pneumatic, etc.)

Discotom-60 /-65

Instruction Manual

1

User’s Guide

Table of Contents Page

1. Getting Started ............................................... 3

Checking the Contents of the Packing Box........................................3

Getting Acquainted with Discotom .....................................................4

Noise Level ........................................................................................5

Power Supply.....................................................................................6

Connection to an External Exhaust System.......................................8

Connecting a Recirculation Cooling Unit............................................9

2. Basic Operation..............................................10

Using the Controls............................................................................10

Front Panel Controls of Discotom...........................................10

Front Panel Controls ........................................................................11

Cooling Valve Positions ...................................................................12

Flush Hose.......................................................................................12

Cleaning of Flush Hose Nozzle........................................................12

Setting the Language.......................................................................13

Moveable Table................................................................................13

Y-Table ...................................................................................13

Reading the Cutting Display.............................................................14

Changing Cutting Mode and Cutting Parameters.............................15

Changing Cutting Mode..........................................................15

Changing Cutting Parameters.................................................16

Using Motor Load and Temperature Display..........................22

Automatic Feed Speed Control...............................................22

Overload Protection .........................................................................23

Fitting or Changing the Cut-off Wheel..............................................24

Clamping the Workpiece..................................................................24

Positioning the Cutting Table...........................................................24

Starting/Stopping the Cutting Process .............................................25

Automatic Cutting....................................................................25

Manual Cutting........................................................................26

Combining Manual and Automatic Operation.........................26

Stop Modes......................................................................................27

Relative Stop Position............................................................27

Absolute Stop Position ..........................................................28

Automatic Stop......................................................................29

Variable Motor RPM (D-65 only)......................................................30

Recommended Settings:.........................................................30

Cleaning...........................................................................................32

Flushing the Cutting Chamber................................................32

Discotom-60 /-65

Instruction Manual

2

3. Routine Maintenance.......................................33

Daily Service ....................................................................................33

Weekly Maintenance........................................................................33

Monthly Maintenance.......................................................................33

Replacing the Cooling Water..................................................33

Yearly Service..................................................................................34

Inspection of Guard.................................................................34

Discotom-60 /-65

Instruction Manual

3

1. Getting Started

In the packing box you should find the following parts:

1 Fork spanner (24 mm) for cut-off wheel

1 Connector pipe for water outlet

3 Elbow pipes for water outlet

1 Outlet hose 2 m,

for connection to external cooling unit

3 Hose clamps, 35-60 mm

1 Grease for maintenance/lubrication of the spindle

1 Oil for maintenance of cutting table

1 Set of Instruction Manuals

Remove the bolts from all of the transport brackets that secure the

Discotom to its transport pallet.

Remove the brackets.

Discotom should be placed on a table strong enough to support a

minimum of 171 kg/ 377 lbs.

Struers recommends the use of the Table Unit, which is designed for

use with Discotom machines, see “Accessories”.

Checking the Contents

of the Packing Box

Unpacking Discotom

Placing Discotom

Discotom-60 /-65

Instruction Manual

4

Take a moment to familiarise yourself with the location and names of

the Discotom’s components.

Cutting handle

Control panel

Y-table joystick

Emergency stop

Cooling valve

Main power switch

Cut-off wheel locking handle

Getting Acquainted

with Discotom

Front View

Side view, right

Discotom-60 /-65

Instruction Manual

5

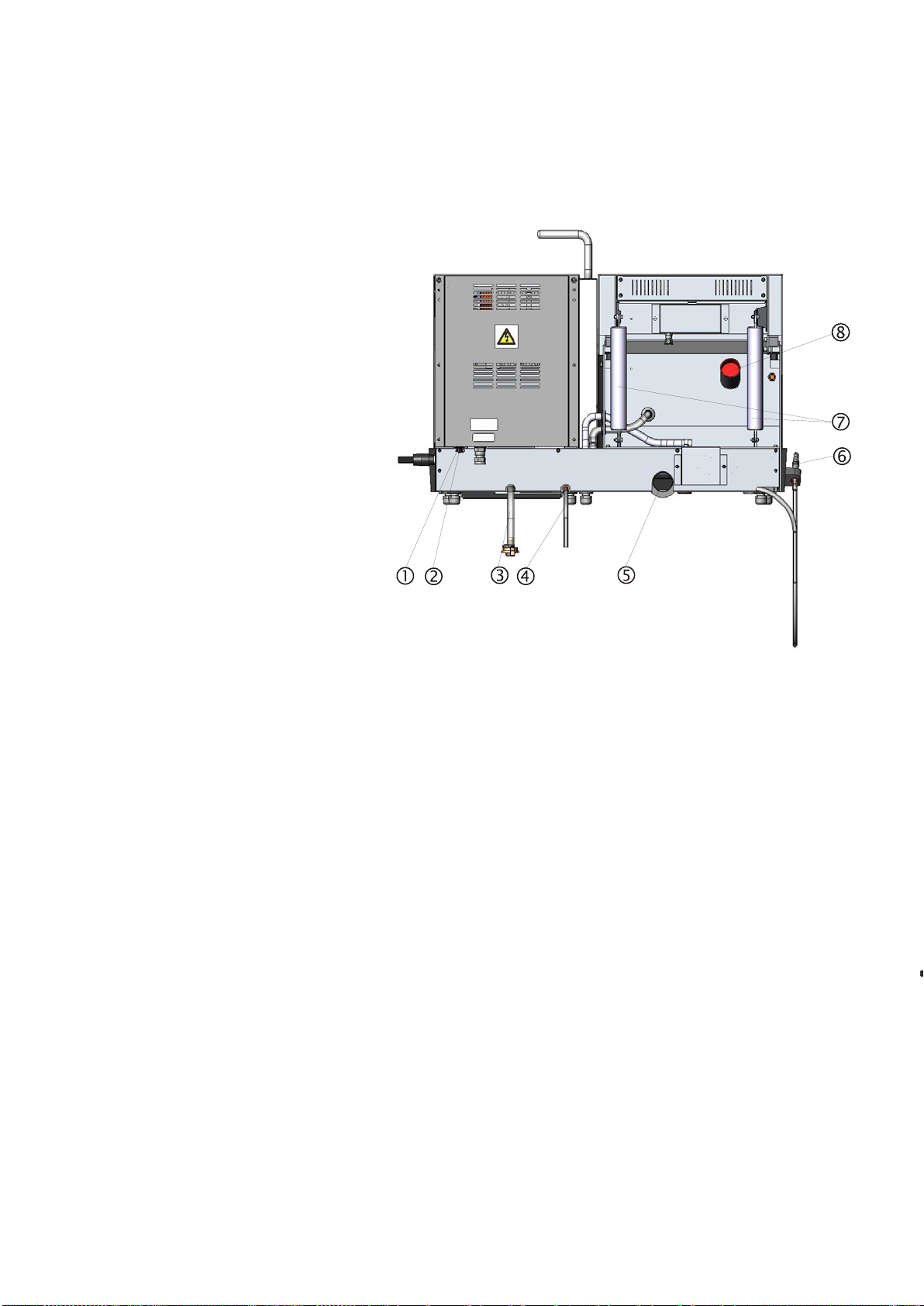

Cooli unit connection

Service socket (RS232)

Water intlet

Drainage hose

Water outlet flange

Flushing hose

Cutting chamber hood springs

Exhaust connection

Approx. 67 dB (A) measured at idle running, at a distance of

1.0 m/39.4” from the machine.

Rear View

Noise Level

Discotom-60 /-65

Instruction Manual

6

First check that the mains voltage corresponds to the voltage

stated on the type plate on the side of the machine.

Discotom-60 is factory mounted with an electric cable.

Mount a plug on the cable according to the following:

EU cable UL cable

L1Brown

L2Black

L3Black or grey

Earth Yellow/green

Neutral Blue (Not used)

L1Black

L2Red

L3Orange/ turquoise

Earth Green (or Yellow/green)

Neutral White (Not used)

Check that the cut-off wheel rotates in the direction indicated by the

arrow on the cut-off wheel guard. If the direction of rotation is

incorrect:

EU cable UL cable

Switch two of the phases Switch phases L1and L2

Power Supply

Discotom-60

Direction of the Cut-off Wheel

Discotom-60 /-65

Instruction Manual

7

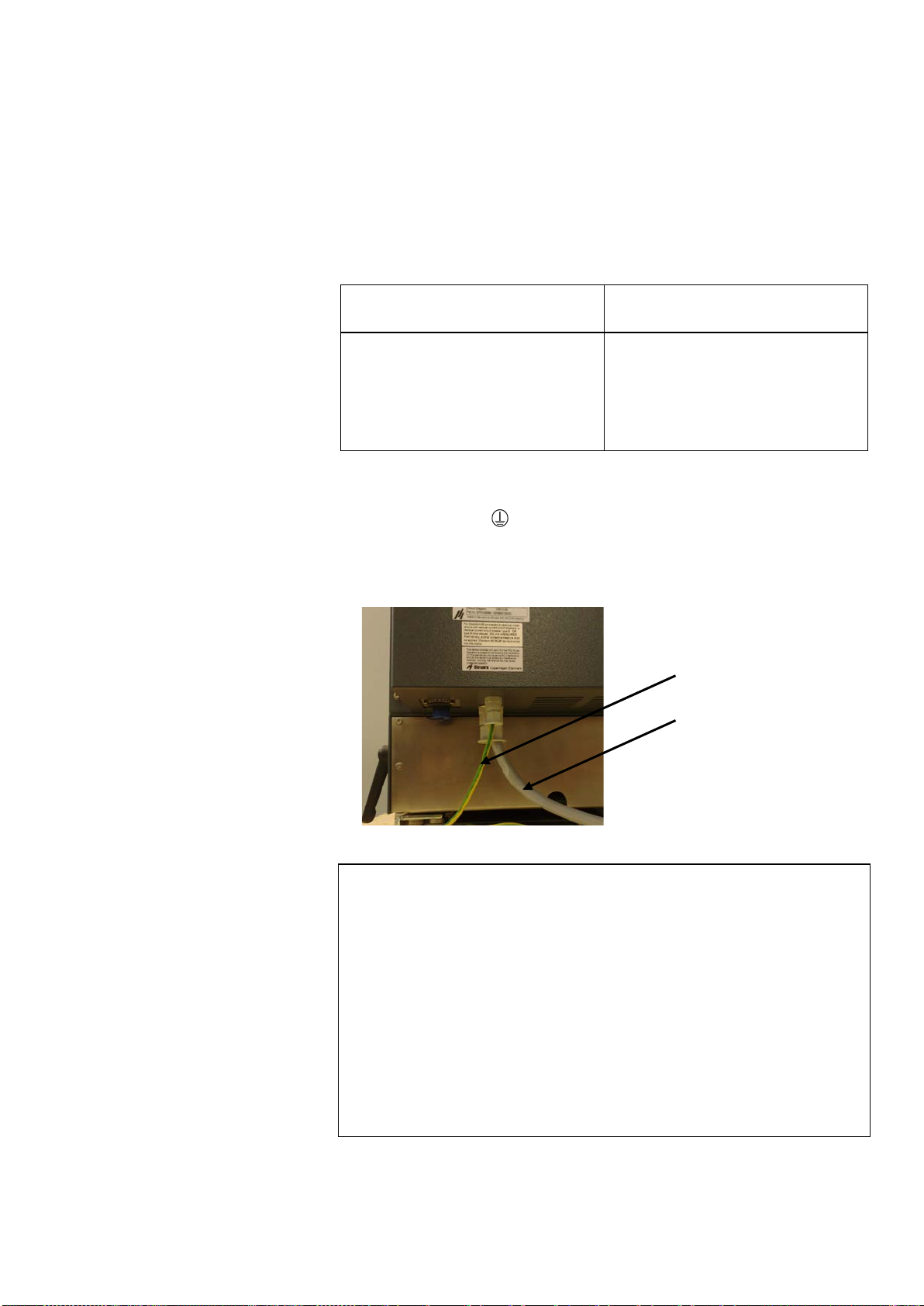

Discotom-65 is factory mounted with an electric cable and an

additional wire for earth connection. Both MUST be hard-wired into

the mains (ref. EN 50178 / 5.2.11.1):

EU cable UL cable

L1Brown

L2Black

L3Black or grey

Earth Yellow/green

Neutral Blue (Not used)

L1Black

L2Red

L3Orange/ turquoise

Earth Green (or Yellow/green)

Neutral White (Not used)

The second Protective Earth must be earthed by connection to a

terminal marked or PE.

Alternatively, use a system whereby there is an automatic

disconnection of the supply in case of loss continuity of the

protective conductor.

Both requirements refer to the European standard EN 50178 / 5.2.11.1.

Similar standards apply in North America.

Discotom-65

Important:

For Electrical Installations with Residual Current Circuit Breakers

For Discotom-65 connected to electrical installations with residual current

circuit breakers, a residual current circuit breaker,

type B time delayed, 30 mA is REQUIRED

(ref. EN 50178 / 5.2.11.1).

For Electrical Installations without Residual Current Circuit Breakers

The equipment must be protected by an insulation transformer

(double-wound transformer)

Please contact a qualified electrician to verify which option is suitable for the

local installation setup.

Protective earth

Electric cable

Discotom-60 /-65

Instruction Manual

8

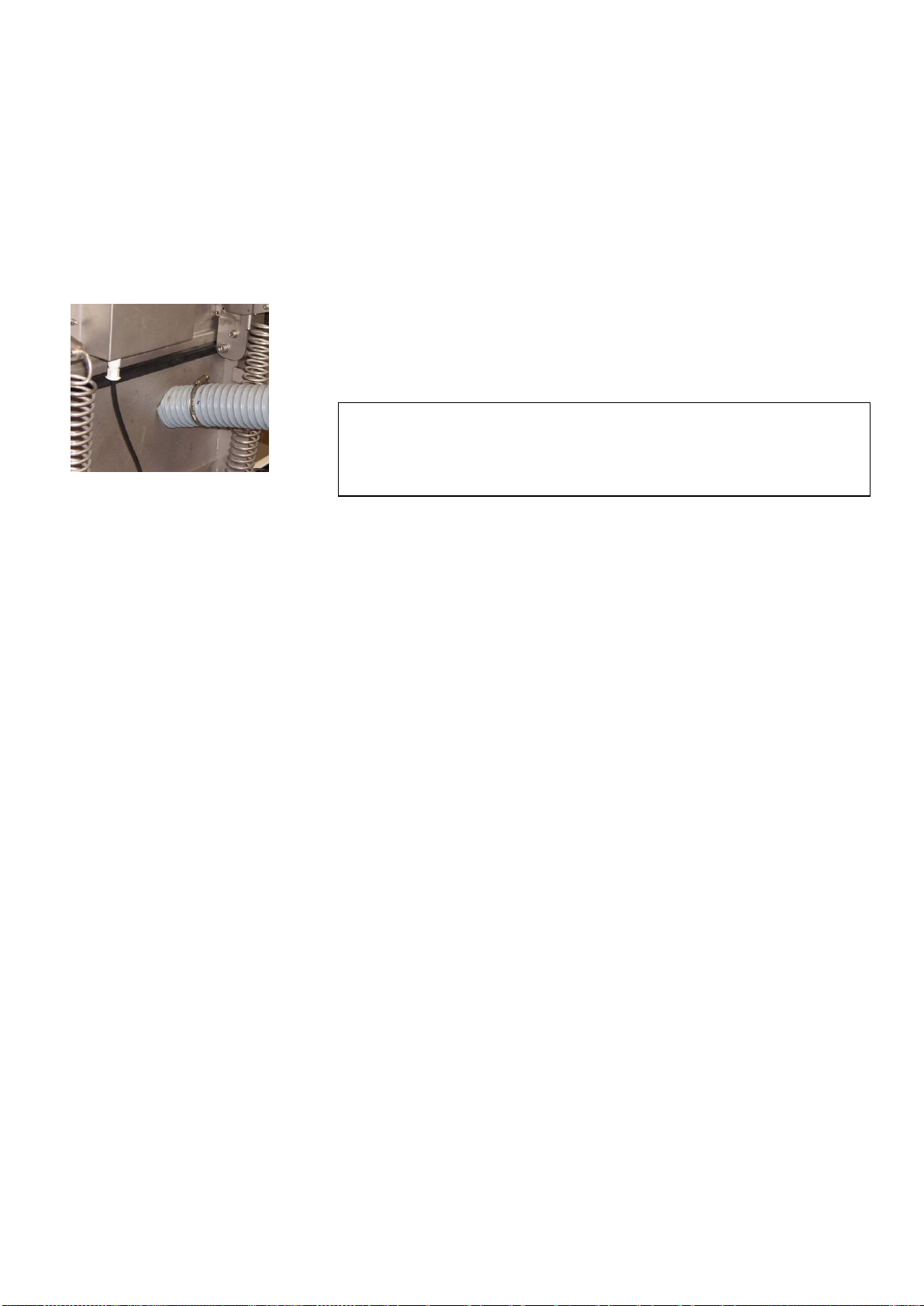

Struers recommends the use of an exhaust system, as workpieces

may emit harmful gases when cut. The exhaust system will also

reduce the level of water condensation on the sides of the protection

guard.

To connect the Discotom to an exhaust system:

Remove the red cap from the flange.

Mount an exhaust hose from your local exhaust system onto the

flange (50 mm (approx. 2") dia.).

Connection to an External

Exhaust System

Important

If no exhaust is connected, damp air (produced by the cutting process) may

escape from the cutting chamber and penetrate into other areas of the

cabinet. This may cause damage to components and shorten the lifetime of

the machine.

Discotom-60 /-65

Instruction Manual

9

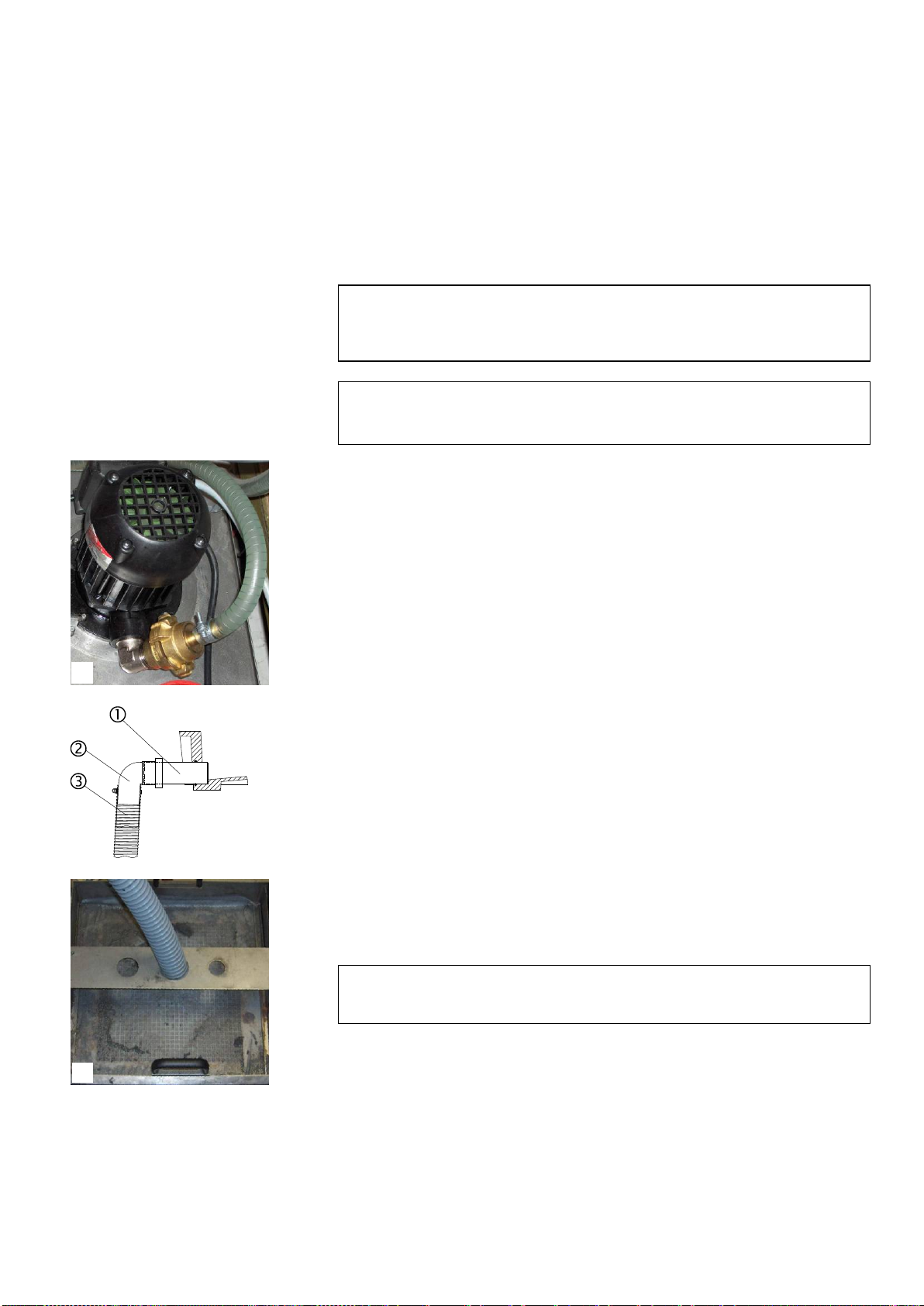

To ensure optimal cooling, Discotom can be fitted with a Cooli unit.

Cooling System 5 is a Cooli configuration designed for use with

Discotom.

To connect the Discotom to a Recirculation Cooling Unit:

Plug the Cooli control unit’s communication cable into the

Discotom’s control socket.

Connect the water inlet hose to the Cooli pump using the quick

coupling (A).

Connect the other end of the hose to the Discotom water inlet.

Insert the connector pipe in the water outlet on the back of

Discotom and mount the 90° elbow pipe . Lubricate the sealing

ring with grease or soap to facilitate insertion. (Use the other

elbow pipe if more suitable).

Mount the outlet hose onto the elbow pipe and clamp using a

hose clamp.

Check that the outlet hose slopes downwards when connected. If

necessary adjust the length of the hose.

Insert the other end of the hose into the mounting hole in the

bracket on top of the Cooli filter unit (B).

Connect the cooling unit to the mains power supply.

Place the drainage hose in the tank of the Cooling Unit or lead to

drain.

Connecting a Recirculation

Cooling Unit

Note:

Cooling System 5 includes a static filter.

For intensive use, and for materials generating a lot of swarf,

a bandfilter such as Coolimat-200 is recommended.

Note

Before connecting the cooling unit to the Discotom, follow the instructions in

the Cooling Units Instruction Manual to prepare it for use.

IMPORTANT

Before connecting, check that the mains voltage corresponds to the voltage

stated on the type plate on the side of the machine.

Drainage Hose

A

B

Discotom-60 /-65

Instruction Manual

10

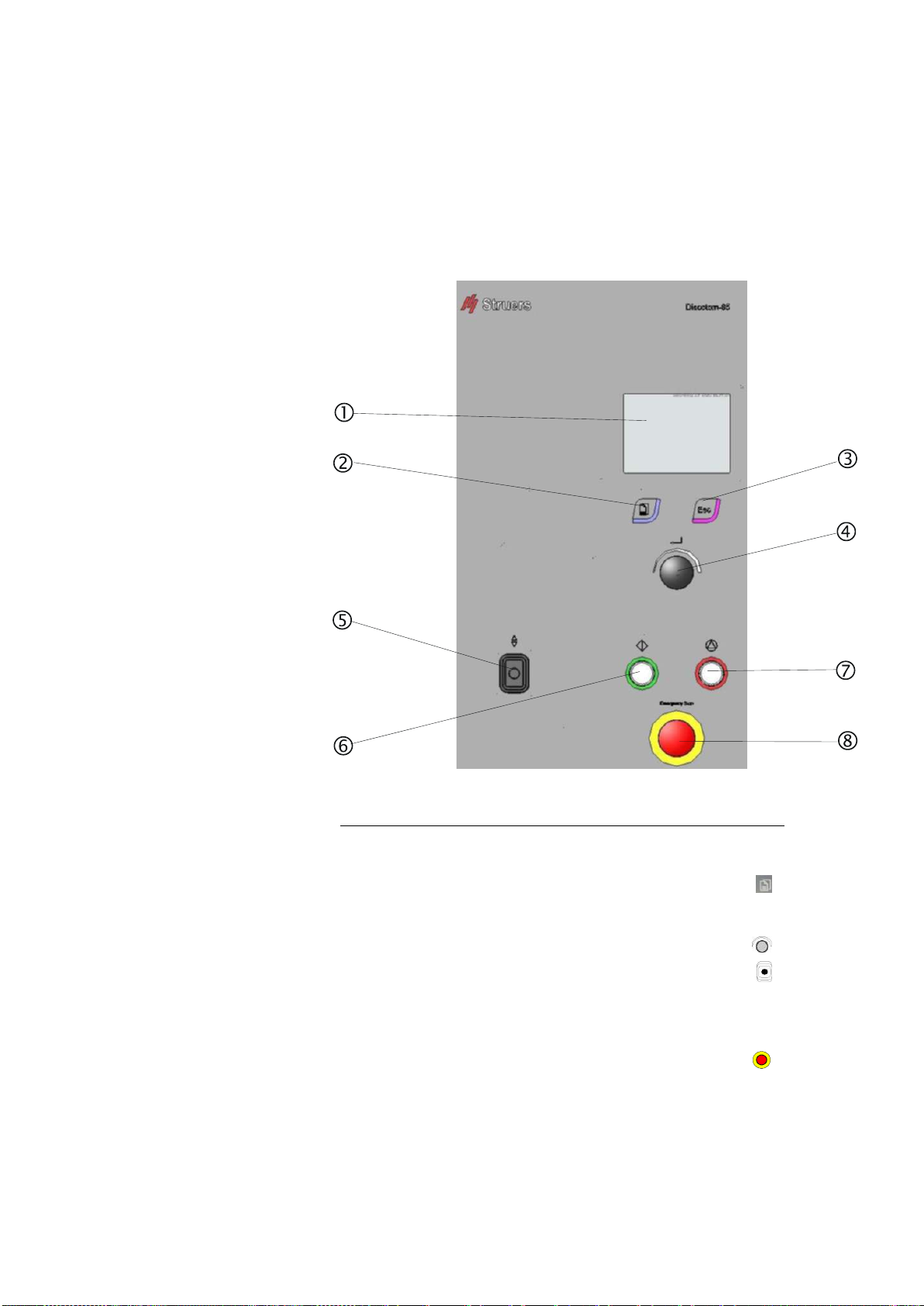

2. Basic Operation

Control name Symbol

DISPLAY

MENU KEY..............................................................................

ESCAPE ..............................................................................ESC

MULTI-FUNCTION KNOB .....................................................

JOYSTICK .............................................................................

START....................................................................................

STOP......................................................................................

EMERGENCY STOP..............................................................

Using the Controls

Front Panel Controls

of Discotom

Discotom-60 /-65

Instruction Manual

11

Name Item Function

Name Item Function

DISPLAY

The Discotom’s display.

JOYSTICK

Move up-or down to position

the Y- table.

MENU KEY

Menu dependent multi-function

key. See the bottom line of the

individual screens.

START

Starts the machine and

recirculation unit and/or band

filter.

ESCAPE Moves one step backward in

menus. If modified parameters

have not been stored, changes

are lost.

STOP

Stops the machine and

recirculation unit and/or band

filter.

MULTI-

FUNCTION

KNOB

Push knob to select function.

Turn knob to adjust settings.

Push knob to store modified

settings.

EMERGENCY

STOP

Push the red button to stop.

Pull the red button to release.

Front Panel Controls

Discotom-60 /-65

Instruction Manual

12

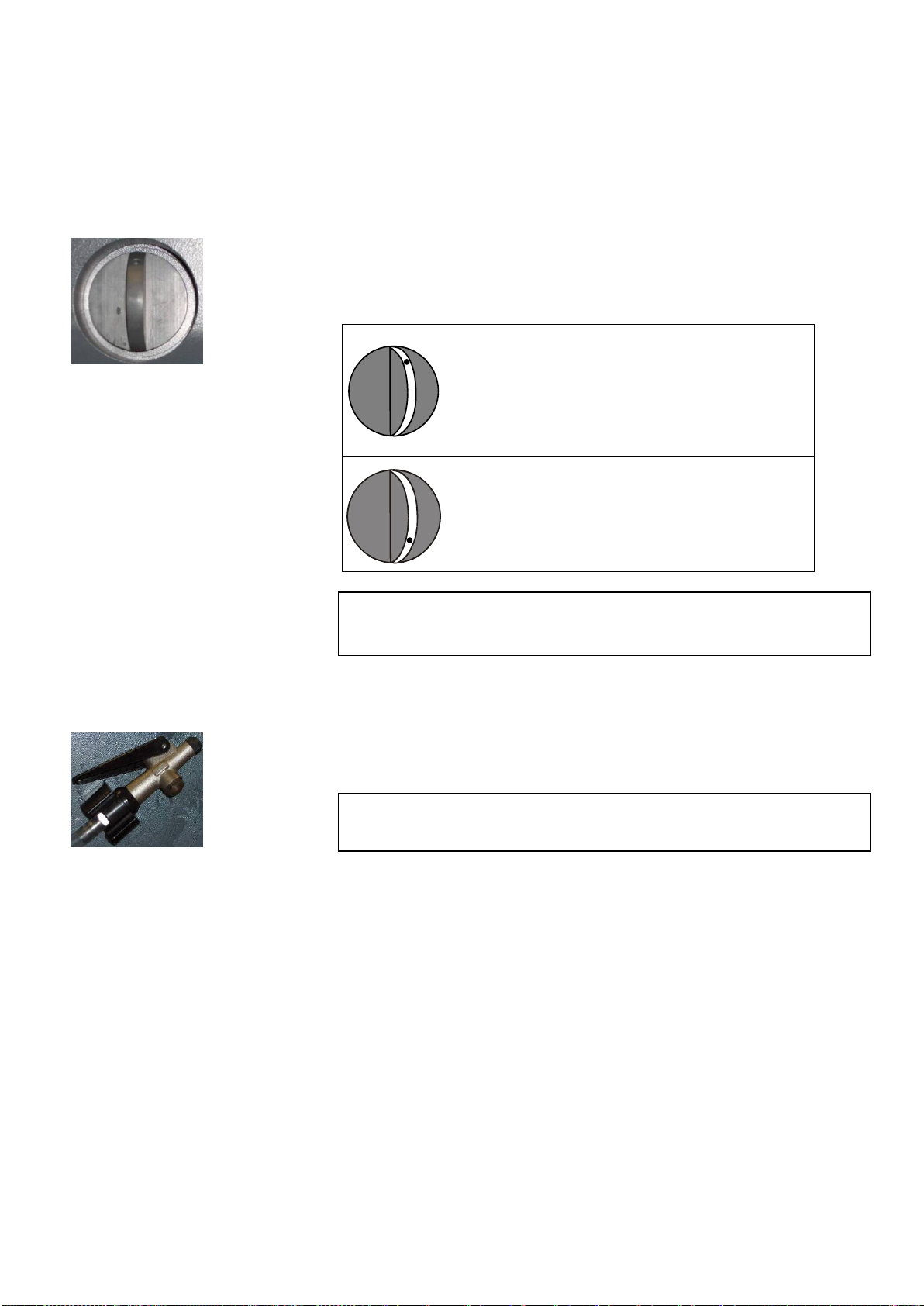

The cooling valve switches the flow of cooling fluid between the

cutting chamber (cutting) and the flushing hose (cleaning).

During cutting the valve is placed in the vertical position to cool the

cut-off wheel. During cleaning the valve is turned clockwise to divert

cooling fluid to the flushing hose.

Turn the valve anti-

clockwise (dot to top)

for cut-off wheel

cooling.

Cutting position

Turn the valve

clockwise (dot to

bottom) for cleaning. Cleaning position

Press down the lever, on the top of the flush hose, to open the

hose’s on/off valve and to adjust the flow of water.

For instructions on how to use the flushing hose when cleaning the

Discotom, see “Cleaning”.

The flush hose nozzle may collect swarf, inhibiting the flow of cooling

fluid.

To clean, unscrew nozzle head and rinse under clean water.

Cooling Valve Positions

Please Note

After cleaning, turn cooling valve back to vertical position. START can

not be activated unless the cooling valve is in the cutting position.

Flush Hose

IMPORTANT

Do not move the cooling valve to the cleaning position

until the flush hose is pointing inside the cutting chamber.

Cleaning of Flush Hose Nozzle

Discotom-60 /-65

Instruction Manual

13

When the Discotom is started for the first time, a screen display

prompts selection of a preferred language.

To change the language:

From the CUTTING menu, press MENU

button once to

select CONFIGURATION Menu.

Turn knob to navigate between parameters in the

CONFIGURATION Menu.

Push knob to select LANGUAGE. A pop-up menu

appears.

From the pop-up menu, select your preferred language

and enter the setting by pushing the knob.

Press ESC button to move from CONFIGURATION Menu

to Cutting menu.

The Y-table is a motor driven, movable table. Using the joystick (see

“Control Panel Functions”) the table can be moved backwards and

forwards. The Y-table is especially useful for cutting wide

workpieces.

Setting the Language

Moveable Table

Y-Table

Note:

When Discotom is switched on, the cutting table will move to the front

reference position (the latest position of the cutting table).

However, when Discotom has been switched on and off 10 times, the

cutting table will firstly move to the front of the cutting chamber and then to

the back. This automatic movement helps keep the two guide shafts free of

cutting swarf.

Discotom-60 /-65

Instruction Manual

14

The Cutting Display displays three types of information:

A: Cutting Mode

B: Cutting Parameters, and

C: Motor Information

The top area of the display (A) displays the selected Cutting Mode:

Manual Cutting or Automatic Cutting mode.

In Automatic Cutting mode, the middle area of the display (B)

displays information about the Cutting Parameters: Feed speed, Stop

position and Motor RPM (D-65 only).

The Cutting Parameters can be set both before and during cutting.

The set value is displayed to the left of the bar graph. The actual

value (during cutting) is displayed to the right of the bar graph.

The bottom area of the display (C) displays Motor information: Motor

load and Motor temperature. The values displayed are in relative (%)

values.

Reading the Cutting Display

Cutting Mode

Note:

In Manual Cutting mode, Cutting Parameters are not displayed.

This area of the display will be blank.

Cutting Parameters

Motor Information

B

A

C

Discotom-60 /-65

Instruction Manual

15

The Discotom has two cutting modes: Manual and Automatic.

To toggle between these two modes:

Turn knob to highlight cutting mode.

Push knob to toggle between the two cutting modes.

Changing Cutting Mode and

Cutting Parameters

Changing Cutting Mode

Discotom-60 /-65

Instruction Manual

16

In automatic cutting mode the Discotom applies the selected cutting

parameter values for: Feed speed, Stop mode and Motor RPM (D-65

only).

To adjust the values of these parameters:

Turn the knob to highlight a selected cutting parameter.

Push the knob to allow editing of the highlighted parameter. Turn

the knob to change the value of the parameter.

Push the knob to store the new value.

Actual values of the cutting parameters: Feed speed, Stop position

and Motor RPM (D-65 only) are displayed to the right of the columns

(A).

Turn the knob to change the value of the selected cutting parameter.

The arrow above the column will move to reflect the new setting (B).

Changing Cutting Parameters

Turn knob to select Cutting

Parameter.

Push knob to allow editing of Cutting

Parameter.

Turn knob to adjust value.

Push knob to store new value.

B

A

This manual suits for next models

1

Table of contents

Languages:

Other Struers Cutter manuals