Introduction

Thank you for your purchase of a C185A air source

heat pump water heater! With this purchase, you now

own one of the most ecient and reliable large-vol-

ume water heaters available in the world today. This

unit will produce potable hot water from a highly ef-

cient and capable heat pump, helping end users

reach their carbon reduction, electrication, eciency,

and operating cost reduction goals.

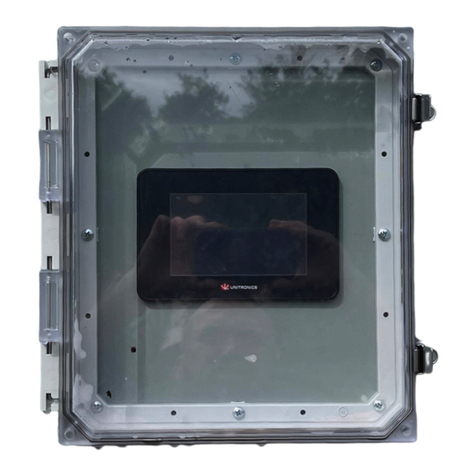

The C-Series heat pumps use R-134a refrigerant, are

available in single-pass or multi-pass congurations,

and are capable of providing single-pass water heat-

ing to appropriate external storage vessels with up to

160°F water, and can perform at outdoor tempera-

tures as low as 40°F (35°F with optional CWP/Active

Defrost accessory). Models are available for 230V

and 460V 3-phase power, include internal power qual-

ity monitoring, and all units are ready to be integrated

into BMS systems with the purchase of an additional

BMS Gateway accessory. C-Series air source units

can also be congured with axial fans for ductless ap-

plications, or blower fans for ducted applications.

Nyle’s C-Series units are not intended for primary

space conditioning. When installed in suitable condi-

tioned spaces, they can provide supplemental cooling

and/or dehumidication benets.

C185A Air Source Heat Pump Water Heater

(Axial Model Shown)

Safety Information

The proper installation, use and servicing of this com-

mercial heat pump water heater is extremely import-

ant to your safety and the safety of others.

Many safety-related messages and instructions have

been provided in this manual and on your own heat

pump water heater to warn you and others of a poten-

tial injury hazard. Read and obey all safety messag-

es and instructions throughout this manual. It is very

important that the meaning of each safety message

is understood by you and others who install, use, or

service this heat pump water heater

This is the safety alert symbol. It is used

to alert you to potential personal injury

hazards. Obey all safety messages that

follow this symbol to avoid possible in-

jury or death.

DANGER

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in injury or death.

WARNING

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in injury or death.

CAUTION

CAUTION indicates a potentially hazardous situation

which, if not avoided, could result in minor or moderate

injury.

CAUTION

CAUTION used without the safety alert symbol indi-

cates a potentially hazardous situation which, if not

avoided, could result in property damage.

All safety messages will generally tell you about the type

of hazard, what can happen if you do not follow the safety

message, and how to avoid the risk of injury.

The California Safe Drinking Water and Toxic En-

forcement Act requires the Governor of California

to publish a list of substances known to the State of

California to cause cancer, birth defects, or other re-

productive harm, and requires businesses to warn of

potential exposure to such substances.

This product contains a chemical known to the State

of California to cause cancer, birth defects, or other re-

productive harm. This appliance can cause low level

exposure to some substances listed in the Act.