5

Data Logging

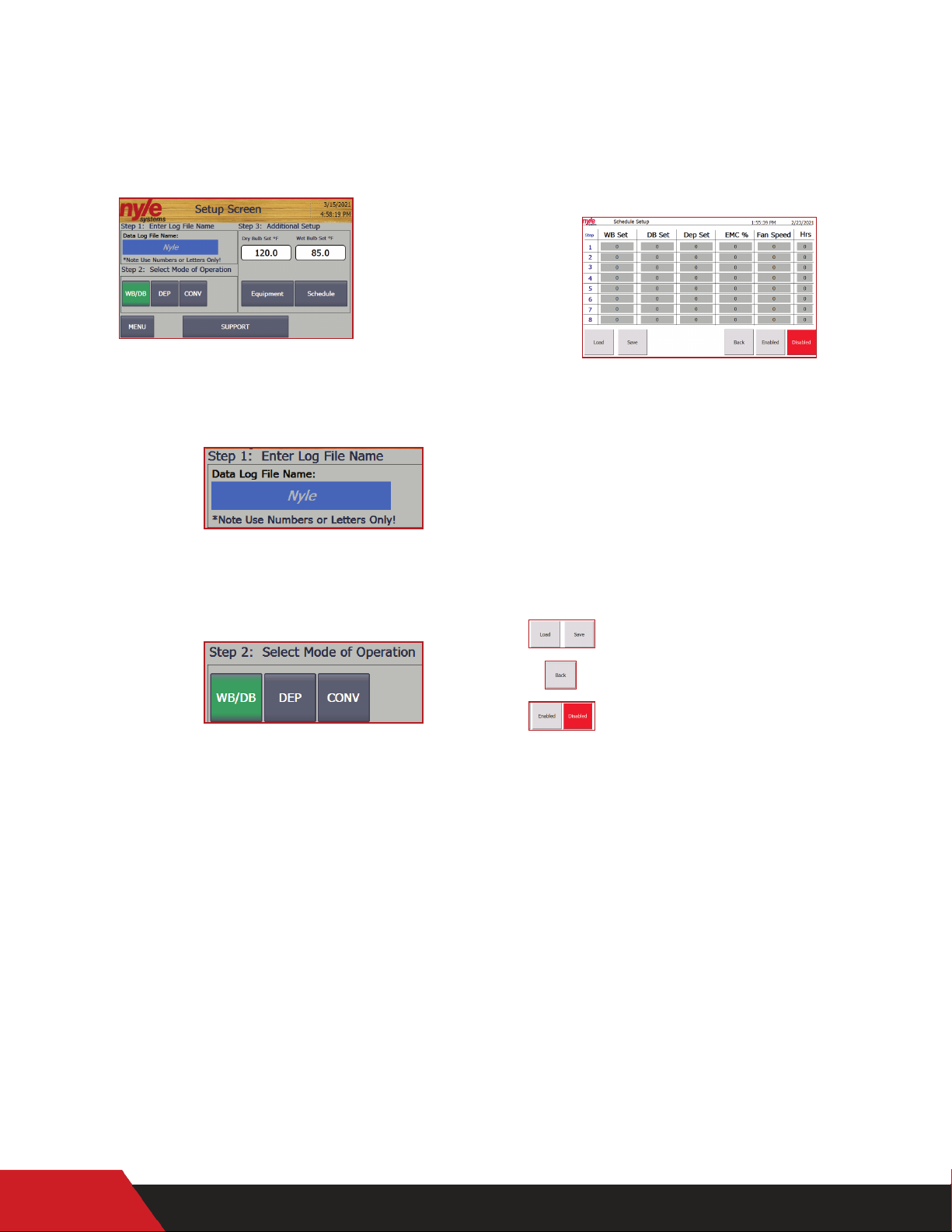

Entering a Schedule

A new schedule can be entered either manually or

by pressing the LOAD button. If no previous schedules

have been saved, the HMI will not be able to load

a schedule into the PLC control. Navigate to the

SETUP screens and then to Schedule to begin the

schedule control process.

On the main schedule screen the full 8 step schedule

that is currently loaded into the PLC will be displayed.

To change values in that schedule simply touch on

the desired set-point, enter a new value, and press

the return key. Once satised with the currently

loaded schedule, press the “Enabled” key to run via

the automatic set point changing schedule control.

Saving a Schedule

If you would like to SAVE a schedule for later use, rst

enter into the PLC as described above. Once you are

satised with the currently loaded schedule press

the“Save”button to display the save schedule interface.

You may verify the schedule about to be saved by

pressing the up and down arrows displayed on the

left of the screen. Press the arrow facing left to begin

the save process. A pop-up will appear verifying the

save command. Press “Yes” followed by “Save As” to

rename the schedule in a way that makes sense for

the schedule. See image above.

Loading a Saved Schedule

Once a schedule has been saved, it can be reused

over and over for ecient drying processes. To

load a schedule, navigate to the schedule setup

screen. Press the“Load”button to begin the loading

process. Press the left arrow once, and press on the

schedule you want to load into the PLC. Pressing

the “Back” button pushes the new schedule into

the PLC for runtime. Verify the loaded schedule

before pressing the “Enabled” key.

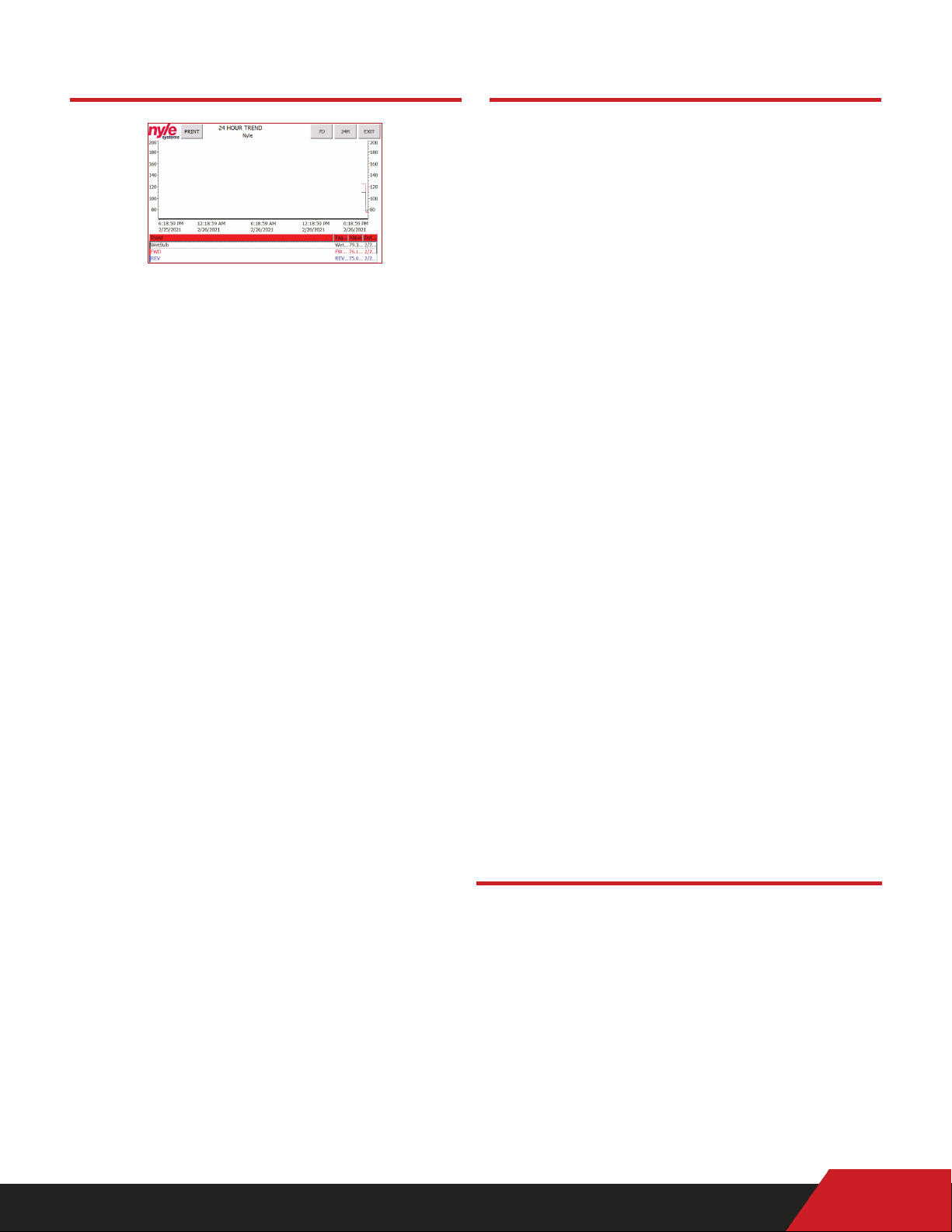

Starting a Data Log

Logging data with the NSC100 control is simple.

Just by entering a LOTID and pressing the start button

automatically begins the data logging process. The

control is capable of storing up to 2 complete cycle

logs in most cases. Once the data log storage space

has been lled up on the PLC, an operator message

will appear requiring the download and clearing of

the logs through the retrieval system.

A log bypass option is available if the data log is not

required. To access this operation press “SETUP”

and afterwards “SUPPORT”. This operator screen

will display all system real time data and the log

bypass button. Press the log bypass button to

disable the data log function.

Retrieving a Data Log

All data logs are stored on the PLC memory card as

a CSV data log le. To obtain the data logs the kiln

operator may either log into the PLC via the web

interface or pull the SD card and copy over the les

to a computer.

To retrieve the data through the web interface, enter

the IP address of the connected PLC into a web

browser connected to the same local area network.

Click “ENTER” to proceed into the default Siemens

web interface. Login using supplied login from

Nyle Systems. Click on“DATA LOGS”to view, download

and clear the data logs stored on the PLC. Each log

le will have the same name as the LOT ID that was

entered when starting the kiln cycle.

Password Change & VNC / WEB Remote

Access Conguration

The HMI screen will be congured to enable VNC

and HTTP web remote access when shipped. However,

you may need to set up remote access after an

upgrade or replacement of the HMI, follow the

steps below.

Enter the control menu by pressing the top right

corner of the screen on the clock.

Schedule Controls

Remote Access