1)

2)

3)

4)

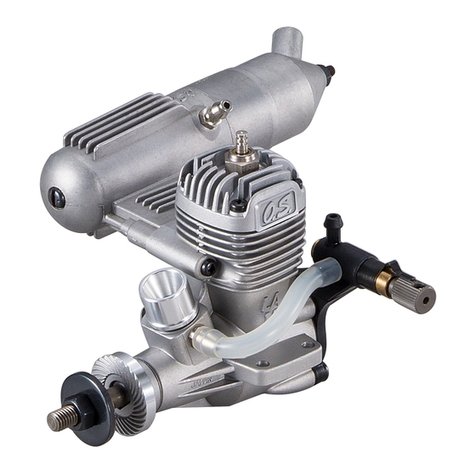

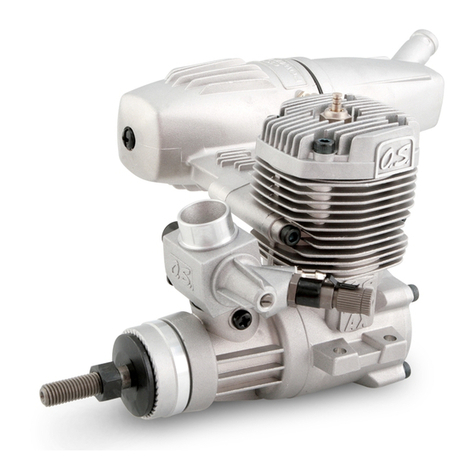

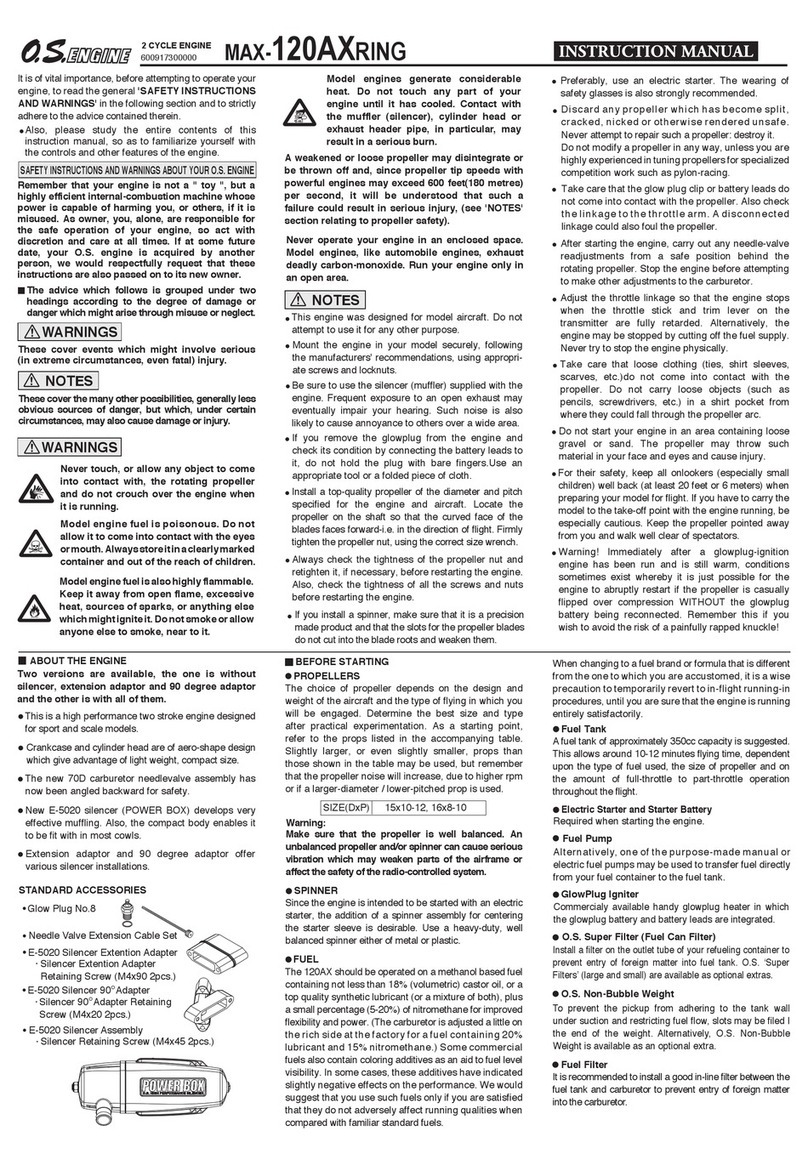

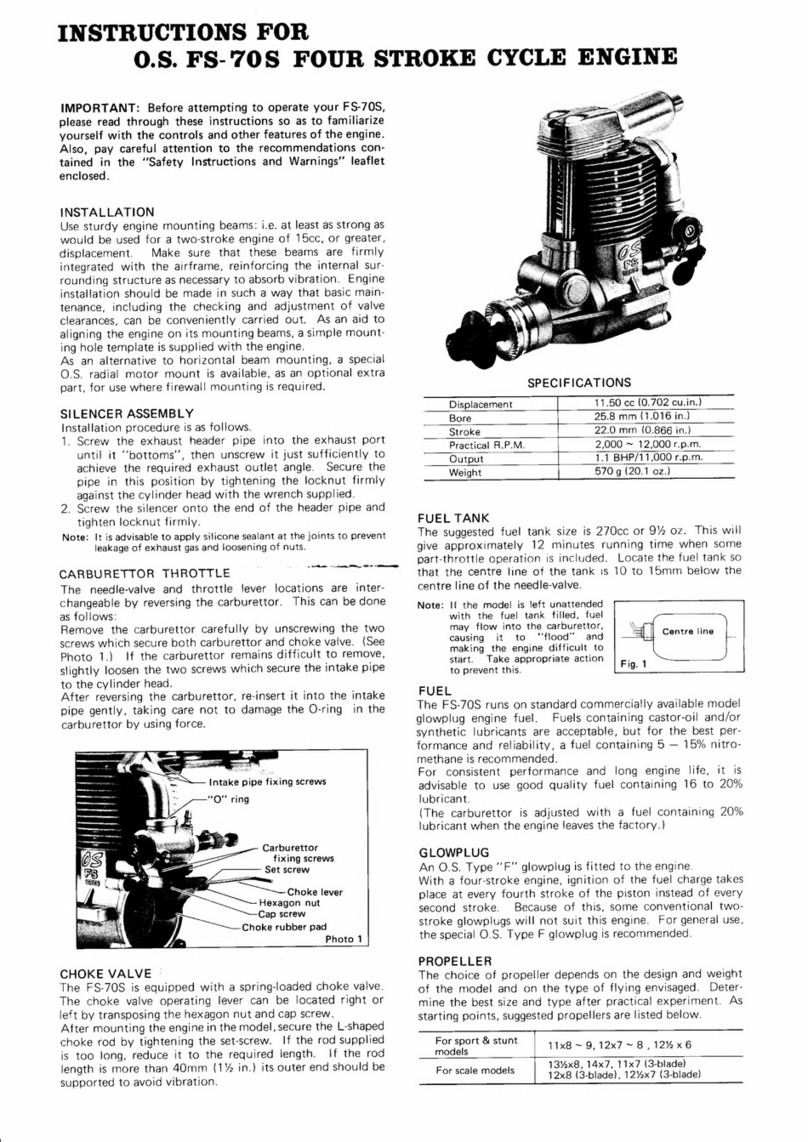

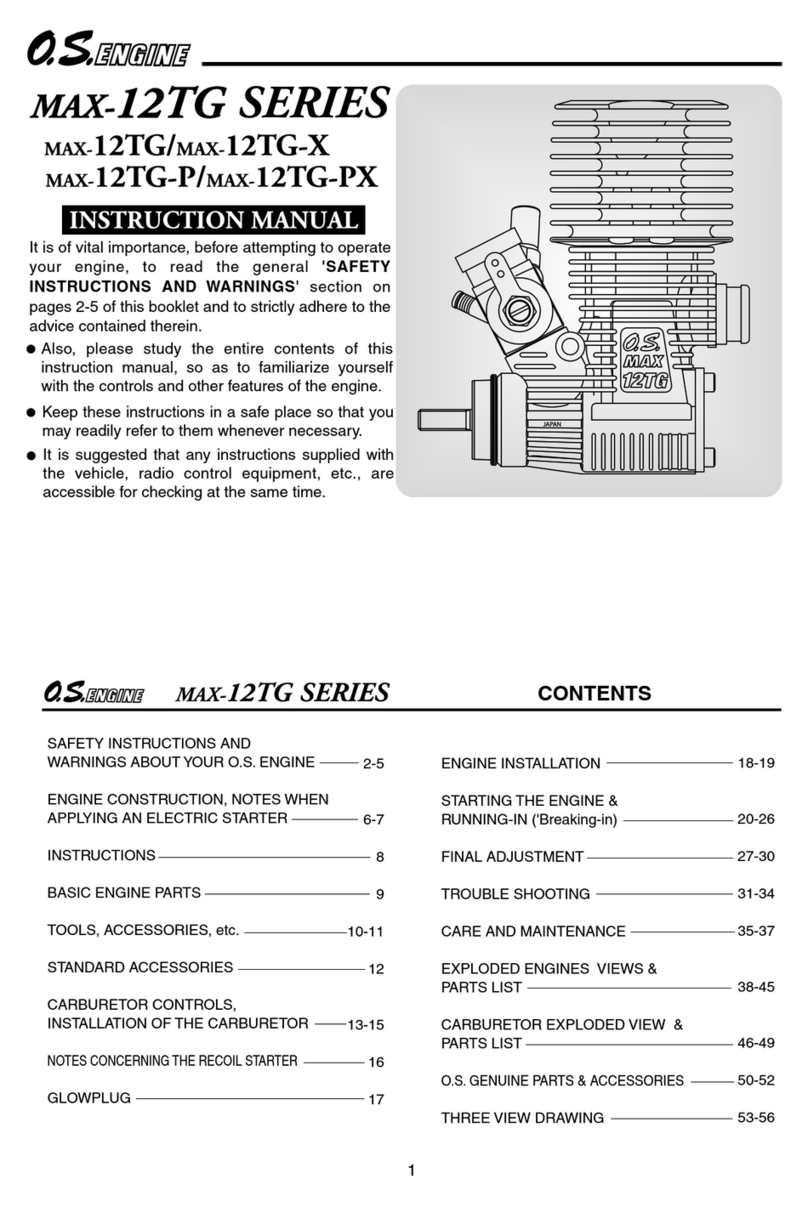

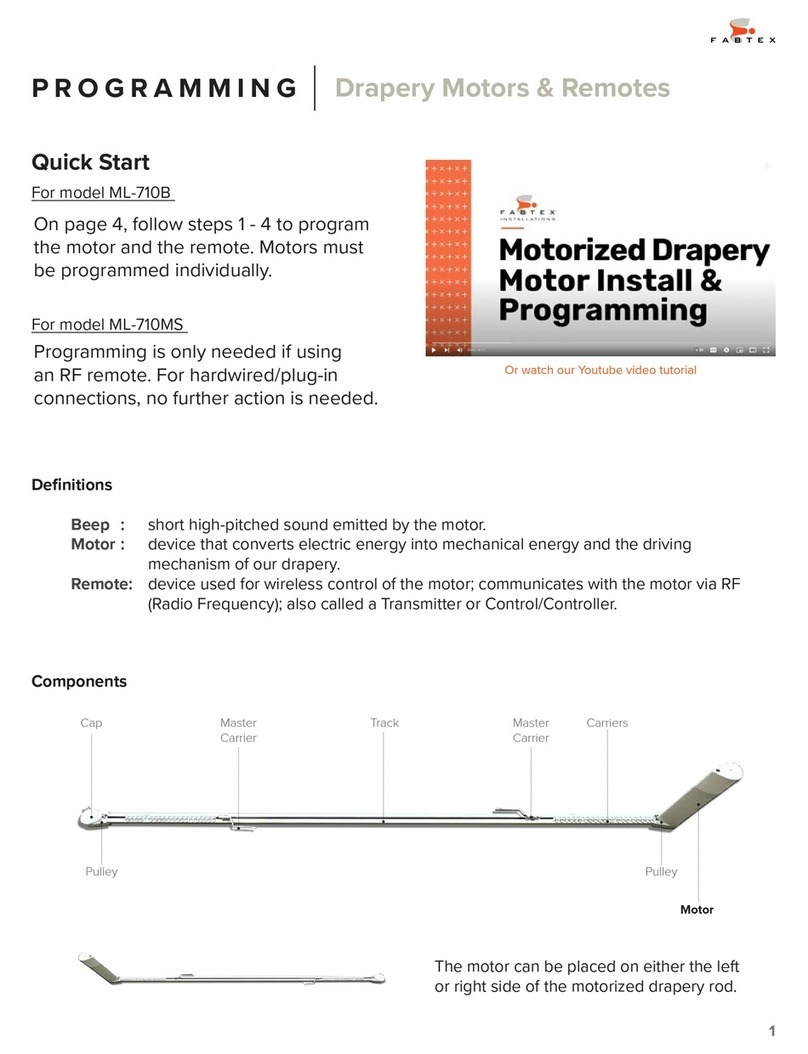

ABOUT THE ENGINE

STANDARD ACCESSORIES

Spark Plug CM-6

Ignition Module

Assembly (IG-05)

PowerBoost Pipe GT15HZ

(Included only in code #38173 GT15HZ600

W/PowerBoost Pipe)

Two stroke gasoline engine for helicopter

It is of vital importance, before attempting to operate your

engine, to read the general 'SAFETY INSTRUCTIONS

AND WARNINGS' in the following section and to strictly

adhere to the advice contained therein.

Also, please study the entire contents of this

instruction manual, so as to familiarize yourself with

the controls and other features of the engine.

SAFETY INSTRUCTIONS AND WARNINGS ABOUT YOUR O.S. ENGINE

The advice which follows is grouped under two

headings according to the degree of damage or

danger which might arise through misuse or neglect.

WARNINGS

NOTES

These cover events which might involve serious

(in extreme circumstances, even fatal) injury.

These cover the many other possibilities, generally less

obvious sources of danger, but which, under certain

circumstances, may also cause damage or injury.

Remember that your engine is not a " toy ", but a

highly efficient internal-combustion machine whose

power is capable of harming you, or others, if it is

misused or abused. As owner, you alone are

responsible for the safe operation of your engine, so

act with discretion and care at all times. If at some

future date, your O.S. engine is acquired by another

person, we would respectfully request that these

instructions are also passed on to its new owner.

Never touch, or allow any object to come

into contact with, the rotating parts.

Gasoline is poisonous. Do not allow it to

come into contact with the eyes or mouth.

Always store it in a clearly marked

container in a cool and dark place and out

of the reach of children. There is a

possibility that it may damage your health.

Model engines generates considerable heat.

Do not touch any part of your engine until it

has cooled. Contact with the muffler (silencer),

cylinder head or exhaust header pipe, in

particular, may results in a serious burn.

Observe the laws and regulations in each

country and district concerning the usage,

transportation and storage of gasoline. Ask for

details at the fire station in each district.

Never operate your engine in an enclosed space.

Model engines, like automobile engines, exhaust

deadly carbon-monoxide. Run your engine only

in an open area.

Do not operate the engine or model alone, or

there is a possibility of injury.

Carry out the mixing of the gasoline and

oil outdoors or in a well ventilated place

away from any source of fire to prevent the

possibility of a fire.

Refill the fuel tank only after the engine is

well cooled down, or there is a danger of fire.

When checking a spark plug with the power source

on, do not hold the plug, plug cap, high tension cord ,

or you will get a shock.

If you have to carry the model to the take-off point

with the engine running, be especially cautious.

Hold the rotor securely and keep well clear of

spectators.

Switch off the ignition module to stop the engine or

fully close the throttle valve via the transmitter to

shut off the fuel supply. Otherwise there is a

possibility of injury.

Immediately after the engine is stopped, the engine

may start with a crank even when the ignition switch

is off. Do not crank the engine, or there is a

possibility of injury.

Be sure to install an externally operable switch for

the ignition system battery to stop the engine if it is

started unintentionally with the radio transmitter

turned off or there is the possibility of injury.

Connect the throttle linkage so that the engine can

be stopped via radio operation.

This engine was designed for model helicopters.

Do not attempt to use it for any other purpose.

Start the engine only after installing it in the model.

Do not start the engine before installing it in the

model, or there is a possibility of injury.

Be sure to use an effective silencer (muffler).

Frequent exposure to an open exhaust may

eventually impair your hearing. Such noise is also

likely to cause annoyance to others over a wide area.

Mount the engine in your model securely, following

the manufacturers’ recommendations.

For their safety, keep all onlookers (especially small

children) well back (at least 10 meters) when

preparing your model for flight.

NOTES

Take care that loose clothing (ties, shirt sleeves, scarves

etc.) do not come into contact with the rotor. Do not carry

loose objects (such as pencils, screwdrivers, etc.) in a

shirt pocket from where they could fall through the rotor

disc.

Always check the throttle linkage.If it is disconnected,

throttle action becomes uncontrollable, which may

result in a serious accident.

Use an electric starter for this engine. The wearing of

safety glasses is also strongly recommended.

Press the rotor head down securely.

Be sure to carry out adjustments of the high speed

needle and slow speed needle after stopping the

engine.

Gasoline is highly flammable. Keep it away

from an open flame, excessive heat,

sources of sparks, or anything else which

might cause it to ignite. Do not smoke or

allow anyone else to smoke near to it.

WARNINGS

Throttle Lever

This engine is designed to be expressly run by gasoline fuel.

Carburetor is set at the factory when the engine leaves the factory.

First run the engine with this factory settings. Refer to the INITIAL OPENING

OF THE NEEDLES described later concerning the factory settings.

Use the Powerboost Pipe GT15HZ (code no. 72148000) with GT15HZ600.

Using a silencer developed for glow engines may cause overheating.

Any damages caused by a use of such silencer are not covered under

warranty.

Be aware of long flight time due to low fuel consumption.

3 Be sure to use a power source of more than 1500mAh capacity for the

receiver when more than 15 minutes of flight is expected. Also, it is suggested

to check the remaining level frequently and charge the batteries if necessary.

Do not run the engine at high rpm abruptly after

starting the engine, or you will be injured by rotating

rotor.

Be sure to use an electric starter and wear safety

goggles and gloves when starting the engine, or you

will be injured.

Since a gasoline engine uses a spark ignition system it is possible that radio

frequency noise from the ignition module can interfere with the receivers

operation if a 72MHz or 40MHz radio is used. Therefore it is recommended that

a 2.4GHz radio system be used, which is not effected by radio frequency noise.

It is recommended to use 2.4GHz transmitter/receiver.

600929900000

Use regular gasoline. (No need to use high octane gasoline.)

Mix commercially available 2 stroke engine oil with a 25:1 ratio. Pre-mixed

gasoline is also usable but do not use such as pre-mixed gasoline which

requires the needle settings far away from the factory settings, otherwise

needle settings would be very difficult.

GT15HZ600

ID.2mm×OD.4mm×150mm Length

Pump Unit PD-08 1pc.

Fluororubber Tube 1pc.

Nylon Nut M3 2pcs.

Pan Head Screw (N.+M3x18) 2pcs.

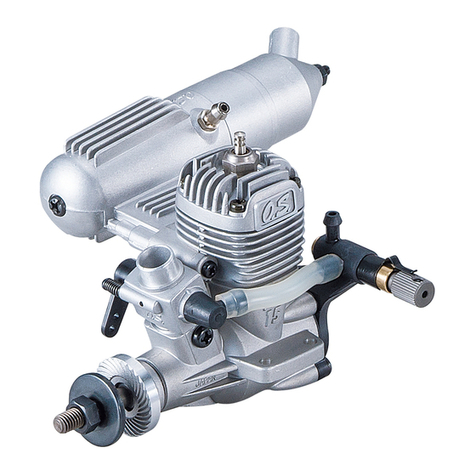

This is a 2-stroke 15cc gasoline engine GT15HZ600

expressly designed for 600 size (50 glow engine class)

R/C helicopters. Its mount size is the same as GT15HZ,

which is for 700 size (90 glow engine class) helicopters,

but the crankshaft diameter of the threaded part is the

same as standard 50 class glow engine. Therefore you

can fit a fan pulley and a clutch of 600 size helicopter

directly to the crankshaft without modifications.The new

61HA carburetor achieves linear power transition with a

combination of pump unit PD-08. #72520000

conversion kit enables a direct fit to ALIGN T-REX 600N

helicopter. The conversion kit consists of Main frames,

a bottom frame, a pinion gear, a set of engine mount,

ball bearings, and collars.

5) Use the exclusive silencer

The cooling fan cover for T-REX 700 DFC (ALIGN

code no. H7NB011XXW) and the optional metal

engine fan (ALIGN code no. HN6060) for T-REX

600N are necessary to fit GT15HZ600 to ALIGN

T-REX 600N helicopter.