Bison BS-20KVA User manual

Safety Precautions

Please read this operation manual carefully, which is closely related to your personal safety. This

manual contains basic safety measures that must be adopted when maintaining your engines. Make

sure that manuals are matched with your engine model before reading.

◆Daily inspection items

Develop a good habit to inspect your engine and engine room with your eyes before turning on and

after shutting down the engine, which will help you to promptly discover leakages of fuel, lubricating

oil or coolant and any other abnormality that has occurred or will occur.

◆Refueling

There are dangers of fire risks or explosions for refueling. Smoking is forbidden and do shut down the

engine. Don’t overfill the fuel tank. Make sure that the cap of fuel tank is securely tightened. Only the

fuel recommended in this manual is allowed to use. Fuel in poor quality may easily result in abnormal

operation or shutdown of engine. Engine operating with poor fuel will lead to blockage of fuel pump

and will cause engine racing. Even worse, engine maybe destroyed and personal injuries maybe

caused.

◆Engine operation

Don’t operate the engine in a place where there are explosive substances or gases because not all the

electrical and mechanical components are properly protected to prevent sparks. It is dangerous to get

close to the engine under operation. Loose cloth, hair, fingers or falling tools may be caught up in

rotating parts, giving rise to serious personal injuries. In case that protective devices are not provided

at the time of engine delivery, you must equip all the rotating parts and hot surfaces with protective

devices to ensure personal safety.

◆Carbon monoxide poisoning

It is only allowed to operate the engine in a well-ventilated environment. If engine is running in an

enclosed space, proper ventilation must be ensured to discharge exhaust gas outdoors from engine

emission and crankcase. Lock the starting switch (Without starting switch lock for the instrument box,

the engine room must be locked or a lockable main switch must be used) to prevent that engine is

turned on by people without permission.

◆Maintenance and service

This manual includes instructions regarding how to perform general maintenance and services safely

www.bezpeka-shop.com

and correctly. Please read this manual carefully before you start with any work. You can obtain more

detailed information in this respect from your distributor. Do not proceed with any work you are not

certain about. Please contact with your distributors and ask them to extend help.

◆Fire and explosion

(1) Fuel and lubricating oil

All the types of fuel, most types of lubricating oil and many chemical products are flammable. Please

read and observe instructions marked on the packages. All the operations related to the fuel system

must be performed after the engine is cooled because fuel splashed on hot surfaces or electrical parts

may cause fire. All the rags immersed in fuel and lubricating oil as well as other flammable materials

must be safely stored in a fire-proofing place. Under certain conditions, rags immersed in the

lubricating oil may be ignited spontaneously. Smoking is strictly forbidden while filling fuel or

lubricating oil, or near the fuel station and inside the engine room.

(2) Spraying liquid for engine start

Don’t start the engine equipped with air preheat device (glow plug/starting heater) using spraying

liquids or equivalents. Otherwise explosion may occur inside the air intake manifold threatening

personal safety.

◆Hot surface and high-temperature liquid

There are dangers of scalding for people operating with high-temperature engines. Pay special

attention to hot surfaces, such as exhaust pipe, turbocharger, oil pan, supercharged air pipe, starting

heater, high-temperature cooling liquids, and high-temperature lubricating oil inside tubes.

◆Chemical products

Most types of chemical products, such as anti-freezing liquids, anti-rust agents, oil seal greases and

degreaser agents are harmful for people’s health. Please read and observe instructions marked on the

packages. Some chemical products, for example, oil seal greases are flammable and harmful for human

body once these substances are inhaled by people. Place chemical products and other hazardous

substances out of reach of children. Please dispose used and residual chemical products in accordance

with regulations for the benefits of environment protection.

◆Cooling system

Don’t open the cap of cooling liquid for high-temperature engines to avoid any scalding as a result of

spraying of steam or high-temperature cooling liquids. If you inevitably open the filling cap or switch

of cooling liquid or you must remove the cooling liquid tubes, please unscrew the cap slowly and

carefully to discharge the pressure before fully opening the filling cap. Pay attention that high-temperature

www.bezpeka-shop.com

cooling liquids may easily give rise to scalding.

◆Lubricating system

Don’t touch high-temperature lubricating oil with your skin to prevent any scalding. Make sure that

pressure has been discharged from the system before you start to work with the lubricating system.

Don’t start or operate the engine when the filling cap of lubricating oil is not closed to avoid the danger

of lubricating oil ejection.

◆Electric welding

Firstly, remove the battery positive and negative cable. Then, disconnect all the cables connecting to

the charging generator. The electric welding clamp must be fixed to the components to be welded while

approaching to the welding point as close as possible. Don’t fix the electric welding clamp on the

engine or have current go through any bearing. Once the welding task is completed, be sure to securely

connect the cables for charging generator and control module before connections of battery cables.

www.bezpeka-shop.com

Preface

BS-30KVA/BS-50KVA Series diesel engines are evolved and developed on the basis of

BS-30KVA/BS-50KVA Series vehicle diesel engines according to the requirements for

electricity-application diesel engines, including models of naturally aspirated types, supercharged

types and supercharged inter-cooling types. The power for this series of diesel engines is defined in

accordance with the ISO standard power specified in section 5.1.2 of GB/T 2820.2-2009

“Reciprocating internal combustion engine driven alternating current generating sets-Part2:

Engines”.This manual introduces various technical specifications, operation instructions and

maintenance methods for BS-30KVA/BS-50KVA Series diesel engines applicable for generator

sets.

Correct operation and maintenance are crucial for safety operation and long service life of diesel

engines. Please read this manual carefully before any operation. Operate and maintain diesel engines

in consistent with the requirements. Refer to part list and service manual for the adjustment, service

and spare part replacement of diesel engines.

Diesel engines you purchase may slightly differ with what has been listed in this manual due

to constant product improvement. For accurate information, please inform the factory of model,

delivery number (purchase order) and serial number marked on the nameplate whenever you want to

purchase the parts.

www.bezpeka-shop.com

Content

1.MAJOR TECHNICAL PARAMETERS OF DIESEL ENGINE

2.OUTLINE DRAWING OF DIESEL ENGINE

2.1 OUTLINE DRAWING OF 4DW81-23D, 4DW81-28D, 4DW91-29D AND 4DW91-38D

2.2 OUTLINE DRAWING OF 4DW92-35D AND 4DW92-42D

2.3 OUTLINE DRAWING OF 4DW93-42D AND 4DW93-50D

2.4 OUTLINE DRAWING OF 4DX21-45D AND 4DX21-53D

2.5 OUTLINE DRAWING OF 4DX22-50D AND 4DX22-60D

2.6 OUTLINE DRAWING OF 4DX23-65D

3.ENGINE MODELAND ITS DEFINITIONS

4.RATED POWER

5.THE OPERATING ENVIRONMENT OF DIESEL ENGINE

6.THE COOLING SYSTEM OF DIESEL ENGINE FOR GENERATORS

7.AIR INLETAND EXHAUST SYSTEM OF DIESEL ENGINE

8.THE FUEL SUPPLY SYSTEM OF DIESEL ENGINE

9.THE SPEED GOVERNING SYSTEM OF DIESEL ENGINE

10. ENGINE OPERATION

10.1 PREPARATION BEFORE ENGINE START

10.2 GETTING PREPARED BEFORE STARTING THE ENGINE

10.3 STARTING THE ENGINE

10.4 ENGINE OPERATION

10.5 ENGINE SHUT-DOWN

11. MAINTENANCE OF DIESEL ENGINE

12. TROUBLESHOOTING OF COMMON FAILURES

...........................................................................................................................................

.............................................................................................................................................

..............................................................................................................

..........................................................................................................................

.......................................................................................................................................

..........................................................................................................

......................................................................................................

.............................................................................................................

..................................................................................................................................................................................

...............................................................................................................................................................................

.............................................................................................................................................................................

................................................................................................................................................

..........................................................................................................................

.........................................................................................................................................................................

.........................................................................................

..................................................................................................................................................................................................

...........................................................................................................

...........................................................................................................

..................................................

...........................................................................................................

.............................................................................................................

.............................................................................................................

.................................................................................................................................................

1

9

9

11

13

15

17

19

22

22

23

24

26

27

27

30

30

31

32

32

33

33

35

www.bezpeka-shop.com

...................................................................................................................................................................

......................................................................................................................................................................

..............................................................................................................................................................................

......................................................................................................................................................................................

...................................................................................................................................................................................

.................................................................................................................

(1) DIESEL ENGINE CANNOT BE STARTED PROPERLY

(2) ABNORMAL OIL PRESSURE

(3) SMOKE IN EXHAUST GAS

(4) INSUFFICIENT POWER

(5) ABNORMAL NOISE

(6) SEVERE VIBRATION

(7) ENGINE OVERHEAT

(8) EXCESSIVELY LARGE OIL CONSUMPTION

(9) SHARPLY INCREASE OF ENGINE SPEED

(10) SHUT-DOWN BY ITSELF

(11) ENGINE SPEED FLUCTUATED WITHIN A CERTAIN RANGE

APPENDIX 1 ALTITUDE AND AIR DENSITY

APPENDIX 2 POWER MODIFIED RATIO OF DIESEL ENGINE

....................................................................................................................................................................................

.........................................................................................................................................................................

...................................................................................................................................

...............................................................................................

.....................................................................................................

........................................................................................................................................

.........................................................................................................................................

35

36

37

38

39

40

40

40

41

41

41

42

42

www.bezpeka-shop.com

1

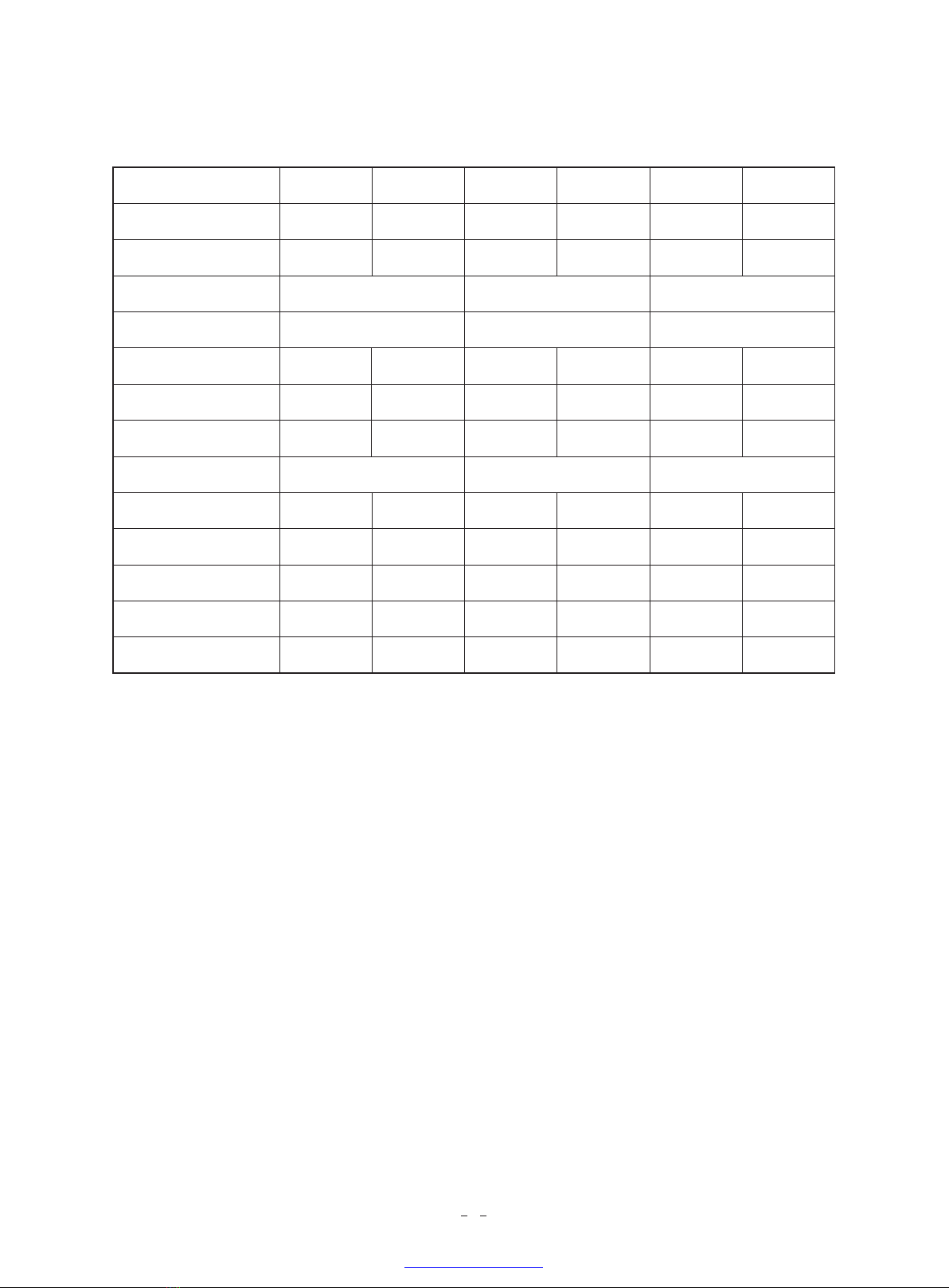

Chapter 1. Diesel Engine Data

Engine Model

Type

Aspiration

Cooling mode

Bore × Stroke (mm×mm)

Compression ratio

Displacement (L)

Dry weight

(basic configuration)(kg)

Prime power

(without fan)(kW)

Fuel system

Emission

Average effective pressure

(MPa)

Speed regulation rate in

steady state

Fuel supply advance angle

Valve clearance in cold state

(mm)

Lubricating oil capacity

(with filter) (L)

Lubricating oil consumption

(L/h)

Fuel consumption of prime

power (g/kW.h)

Fuel consumption ratio of

prime power (g/kW.h)

Permissible max. air intake

resistance (kPa)

Amount of exhaust emission

(m3/min)

Exhaust temperature after

turbine (℃)

Heat dissipation of exhaust

gas(kW)

Max. permissible back

pressure of exhaust pipe(kPa)

Air consumption (m3/min)

Applicable power station

(kW)

Max. Standby power (kW)

4DW81-23D 4DW91-29D 4DW92-35D 4DW92-39D 4DW93-42D

In-line, four-cylinder, four-stroke

Water-cooling

Naturally

aspirated Naturally

aspirated Supercharged Supercharged Supercharged

and inter-cooling

85×95

18:1

2.156

220

17

18.7

12

5%/3%

StageⅡ

0.63

17°CA±1°CA

0.3±0.03

7.8

0.04

4.08

240

1.6

3.7

4.7

470

16.0

6.7

90×100

18:1

2.545

220

21

23

16

5%/3%

StageⅡ

0.66

17°CA±1°CA

0.3±0.03

8

0.05

4.94

235

1.9

3.7

5.5

500

20.2

6.7

90×100

17.5:1

2.545

240

26

29

20

5%/3%

StageⅡ

0.82

17°CA±1°CA

0.3±0.03

8

0.05

5.98

230

2.2

3.7

6.4

450

21.0

6.7

90×100

17.5:1

2.545

240

29

32

22

3%

StageⅡ

0.91

17°CA±1°CA

0.3±0.03

8

0.05

6.67

230

2.5

3.7

7.1

460

23.9

6.7

90×100

17.5:1

2.545

240

31

34

24

5%/3%

StageⅡ

0.97

17°CA±1°CA

0.3±0.03

8

0.05

6.98

225

2.7

3.7

7.8

420

23.9

6.7

Mechanical/

electronic governor Mechanical/

electronic governor Mechanical/

electronic governor Mechanical/

electronic governor Mechanical/

electronic governor

1. Major technical parameters of diesel engine (1500rpm)

www.bezpeka-shop.com

2

Heat dissipation of engine

(kW)

Heat dissipation of coolant

(kW)

Heat dissipation of

inter-cooler (kW)

Speed ratio of fan

Water pump flow rate-lift

(L/s-mH2o)

Recommended battery

capacity(Ah)

Water temperature sensor

parameter

Oil pressure sensor parameter

(MPa)

Flywheel teeth number

Diameter of fan(mm)

Power of fan(kW)

Engine

Generator

Air heater parameter

1.3

13.1

-

170/113

400

1

12V 3.5kW

14V 750W

12V 430W

100×1

109

97℃±2℃

1.6

16.1

-

170/113

400

1

12V 3.5kW

14V 750W

12V 430W

100×1

109

97℃±2℃

2.3

18.9

-

200/113

430

1.5

12V 3.5kW

14V 750W

12V 430W

100×1

109

97℃±2℃

2.6

20.8

-

200/113

-

1.5

12V 3.5kW

14V 750W

-

100×1

109

-

-

2.7

22.1

4.1

200/113

430

2

12V 3.5kW

14V 750W

12V 400W

100×1

109

97℃±2℃

0.08 0

-0.01MPa 0.08 0

-0.01MPa 0.08 0

-0.01MPa 0.08 0

-0.01MPa

2257rpm 60-≥4.5m 2655rpm 71-≥6.3m

www.bezpeka-shop.com

3

Major technical parameters of diesel engine (1500rpm)

102×118

17.5:1

3.86

350

33

36

24

5%/3%

Stage Ⅱ

0.68

14°±1°CA

0.4±0.05

12.5

0.06

7.43

225

2.9

8.3

500

30.4

102×118

17.5:1

3.86

350

39

43

32

3%

Stage Ⅱ

0.81

14°±1°CA

0.4±0.05

12.5

0.06

8.78

225

3.1

9.3

550

31.6

102×118

17.5:1

3.86

380

37

41

30

5%/3%

Stage Ⅱ

0.77

12°±1°CA

0.4±0.05

13

0.05

8.14

220

3.0

8.7

450

28.5

102×118

17.5:1

3.86

380

48

53

38

3%

Stage Ⅱ

0.99

12°±1°CA

0.4±0.05

13

0.05

10.56

220

3.9

11.3

460

37.9

102×118

17.5:1

3.86

380

48

53

38

5%/3%

Stage Ⅱ

0.99

12°±1°CA

0.4±0.05

13

0.05

10.08

210

4.0

11.6

430

36.1

102×118

17.5:1

3.86

380

57

64

46

3%

Stage Ⅱ

1.18

12°±1°CA

0.4±0.05

13

0.05

11.97

210

4.8

13.8

440

44.0

Engine Model

Type

Aspiration

Cooling mode

Bore × Stroke (mm×mm)

Compression ratio

Displacement (L)

Dry weight

(basic configuration)(kg)

Prime power

(without fan)(kW)

Fuel system

Emission

Average effective pressure

(MPa)

Speed regulation rate in

steady state

Fuel supply advance angle

Valve clearance in cold state

(mm)

Lubricating oil capacity

(with filter) (L)

Lubricating oil consumption

(L/h)

Fuel consumption of prime

power (g/kW.h)

Fuel consumption ratio of

prime power (g/kW.h)

Permissible max. air intake

resistance (kPa)

Amount of exhaust emission

(m3/min)

Exhaust temperature after

turbine (℃)

Heat dissipation of exhaust

gas(kW)

Max. permissible back

pressure of exhaust pipe(kPa)

Air consumption (m3/min)

Applicable power station

(kW)

Max. Standby power (kW)

4DX21-45D 4DX21-53D 4DX22-50D 4DX22-65D 4DX23-65D 4DX23-78D

In-line, four-cylinder, four-stroke

Water-cooling

Naturally

aspirated Naturally

aspirated Supercharged Supercharged Supercharged

and inter-cooling Supercharged

Mechanical/

electronic governor Mechanical/

electronic governor Mechanical/

electronic governor

Electronic

governor Electronic

governor Electronic

governor

3.7

6.7

www.bezpeka-shop.com

4

2.5

25.2

-

3.3

26.1

-

3.3

26.7

-

4.2

34.5

-

4.2

34.5

6.0

5.1

41.6

7.1

Heat dissipation of engine

(kW)

Heat dissipation of coolant

(kW)

Heat dissipation of

inter-cooler (kW)

Speed ratio of fan

Water pump flow rate-lift

(L/s-mH2o)

Recommended battery

capacity(Ah)

Water temperature sensor

parameter

Oil pressure sensor parameter

(MPa)

Flywheel teeth number

Diameter of fan(mm)

Power of fan(kW)

Engine

Generator

Air heater parameter

185/110 185/110 185/110

2523r/min 162≥5.4 2000r/min 152-≥5.4 2000r/min 152-≥5.4

128 128 128

420 450 - 520 -

1.3 1.3 2 2 3 3

24V 4.5kW

1000W 28V 6000r/min

24V 4.5kW

1000W 28V 6000r/min

24V 4.5kW

1000W 28V 6000r/min

24V 600W 24V 600W - 24V 600W -

120×2

97℃±2℃- 97℃±2℃- 97℃±2℃-

- - -

0.08-0.01MPa

+0.01 0.08-0.01MPa

+0.01 0.08-0.01MPa

+0.01

www.bezpeka-shop.com

Engine Model

Type

Aspiration

Cooling mode

Bore × Stroke (mm×mm)

Compression ratio

Displacement (L)

Dry weight

(basic configuration)(kg)

Prime power

(without fan)(kW)

Fuel system

Emission

Average effective pressure

(MPa)

Speed regulation rate in

steady state

Fuel supply advance angle

Valve clearance in cold state

(mm)

Lubricating oil capacity

(with filter) (L)

Lubricating oil consumption

(L/h)

Fuel consumption of prime

power (g/kW.h)

Fuel consumption ratio of

prime power (g/kW.h)

Permissible max. air intake

resistance (kPa)

Amount of exhaust emission

(m3/min)

Exhaust temperature after

turbine (℃)

Heat dissipation of exhaust

gas(kW)

Max. permissible back

pressure of exhaust pipe(kPa)

Air consumption (m3/min)

Applicable power station

(kW)

Max. Standby power (kW)

4DW81-28D 4DW91-38D 4DW92-42D 4DW92-45D 4DW93-50D

In-line, four-cylinder, four-stroke

Water-cooling

Naturally

aspirated Naturally

aspirated Supercharged Supercharged Supercharged

and inter-cooling

85×95

18:01

2.156

220

20

22

15

5%/3%

StageⅡ

0.62

17°CA±1°CA

0.3±0.03

7.8

0.04

4.80

240

1.9

3.7

5.6

450

19.1

6.7

90×100

18:01

2.545

240

28

31

22

5%/3%

StageⅡ

0.73

17°CA±1°CA

0.3±0.03

8

0.05

6.44

230

2.3

3.7

6.6

500

24.1

6.7

90×100

17.5:1

2.545

240

31

34

25

5%/3%

StageⅡ

0.81

17°CA±1°CA

0.3±0.03

8

0.05

7.13

230

2.6

3.7

7.6

450

25.0

6.7

90×100

17.5:1

2.545

240

33

36

26

3%

StageⅡ

0.86

17°CA±1°CA

0.3±0.03

8

0.05

7.59

230

2.8

3.7

8.1

450

27.2

6.7

90×100

17.5:1

2.545

240

37

41

30

5%/3%

StageⅡ

0.97

17°CA±1°CA

0.3±0.03

8

0.05

8.14

220

3.2

3.7

9.4

450

28.5

6.7

Mechanical/

electronic governor Mechanical/

electronic governor Mechanical/

electronic governor Electronic governor Mechanical/

electronic governor

Major technical parameters of diesel engine (1800rpm)

5

www.bezpeka-shop.com

6

Heat dissipation of engine

(kW)

Heat dissipation of coolant

(kW)

Heat dissipation of

inter-cooler (kW)

Speed ratio of fan

Water pump flow rate-lift

(L/s-mH2o)

Recommended battery

capacity(Ah)

Water temperature sensor

parameter

Oil pressure sensor parameter

(MPa)

Flywheel teeth number

Diameter of fan(mm)

Power of fan(kW)

Engine

Generator

Air heater parameter

1.5

15.4

-

170/113

400

1.3

12V 3.5kW

14V 750W

12V 430W

100×2

109

97℃±2℃

2.2

21.7

-

170/113

400

1.3

12V 3.5kW

14V 750W

12V 430W

100×2

109

97℃±2℃

2.7

22.1

-

200/113

430

1.8

12V 3.5kW

14V 750W

12V 430W

100×2

109

97℃±2℃

2.9

23.4

-

200/113

-

1.8

12V 3.5kW

14V 750W

-

100×2

109

-

-

3.3

26.7

4.8

200/113

430

2.2

12V 3.5kW

14V 750W

12V 400W

100×2

109

97℃±2℃

0.08 0

-0.01MPa 0.08 0

-0.01MPa 0.08 0

-0.01MPa 0.08 0

-0.01MPa

2708rpm 73-≥6.5m 3186rpm 86-≥9.0m

www.bezpeka-shop.com

7

Major technical parameters of diesel engine (1800rpm)

Engine Model

Type

Aspiration

Cooling mode

Bore × Stroke (mm×mm)

Compression ratio

Displacement (L)

Dry weight

(basic configuration)(kg)

Prime power

(without fan)(kW)

Fuel system

Emission

Average effective pressure

(MPa)

Speed regulation rate in

steady state

Fuel supply advance angle

Valve clearance in cold state

(mm)

Lubricating oil capacity

(with filter) (L)

Lubricating oil consumption

(L/h)

Fuel consumption of prime

power (g/kW.h)

Fuel consumption ratio of

prime power (g/kW.h)

Permissible max. air intake

resistance (kPa)

Amount of exhaust emission

(m3/min)

Exhaust temperature after

turbine (℃)

Heat dissipation of exhaust

gas(kW)

Max. permissible back

pressure of exhaust pipe(kPa)

Air consumption (m3/min)

Applicable power station

(kW)

Max. Standby power (kW)

4DX21-53D 4DX21-61D 4DX22-60D 4DX22-75D 4DX23-82D 4DX23-90D

In-line, four-cylinder, four-stroke

Water-cooling

Naturally

aspirated Naturally

aspirated Supercharged Supercharged Supercharged

and inter-cooling Supercharged

and inter-cooling

Mechanical/

electronic governor Mechanical/

electronic governor Mechanical/

electronic governor

Electronic

governor Electronic

governor Electronic

governor

102×118

17.5:1

3.86

350

39

43

30

5%/3%

Stage Ⅱ

0.67

14°±1°CA

0.4±0.05

12.5

0.06

8.78

225

3.5

3.7

10.1

500

37.7

6.7

102×118

17.5:1

3.86

350

45

50

35

3%

Stage Ⅱ

0.79

14°±1°CA

0.4±0.05

12.5

0.06

10.13

225

3.9

3.7

11.8

620

43.9

6.7

102×118

17.5:1

3.86

380

45

50

35

5%/3%

Stage Ⅱ

0.78

12°±1°CA

0.4±0.05

13

0.05

9.90

220

3.7

3.7

10.6

450

34.7

6.7

102×118

17.5:1

3.86

380

55

60

44

3%

Stage Ⅱ

0.95

12°±1°CA

0.4±0.05

13

0.05

12.10

220

4.5

3.7

13.0

480

45.4

6.7

102×118

17.5:1

3.86

380

60

66

48

5%/3%

Stage Ⅱ

1.04

12°±1°CA

0.4±0.05

13

0.05

12.60

210

5.0

3.7

14.5

450

46.3

6.7

102×118

17.5:1

3.86

380

66

72

56

3%

Stage Ⅱ

1.14

12°±1°CA

0.4±0.05

13

0.05

14.19

215

5.7

3.7

16.3

500

54.7

6.7

www.bezpeka-shop.com

8

Heat dissipation of engine

(kW)

Heat dissipation of coolant

(kW)

Heat dissipation of

inter-cooler (kW)

Speed ratio of fan

Water pump flow rate-lift

(L/s-mH2o)

Recommended battery

capacity(Ah)

Water temperature sensor

parameter

Oil pressure sensor parameter

(MPa)

Flywheel teeth number

Diameter of fan(mm)

Power of fan(kW)

Engine

Generator

Air heater parameter

185/110 185/110 185/110

3027r/min 165-≥8.9 3027r/min 165-≥8.9 3027r/min 165-≥8.9

1000W 28V 6000r/min 1000W 28V 6000r/min 1000W 28V 6000r/min

0.08-0.01MPa

+0.01 0.08-0.01MPa

+0.01 0.08-0.01MPa

+0.01

3.0

27.3

-

3.4

31

-

4.0

29.3

-

4.8

35.8

-

5.3

39.0

7.5

5.8

42.9

8.4

420

2.2

24V 4.5kW

420

2.2

24V 4.5kW

450

2.6

24V 4.5kW

-

2.6

24V 4.5kW

520

3.6

24V 4.5kW

-

3.6

24V 4.5kW

24V 600W

120×2

128

97℃±2℃

24V 600W

120×2

128

-

-

24V 600W

120×2

128

97℃±2℃

-

120×2

128

-

-

24V 600W

120×2

128

97℃±2℃

-

120×2

128

-

-

www.bezpeka-shop.com

9

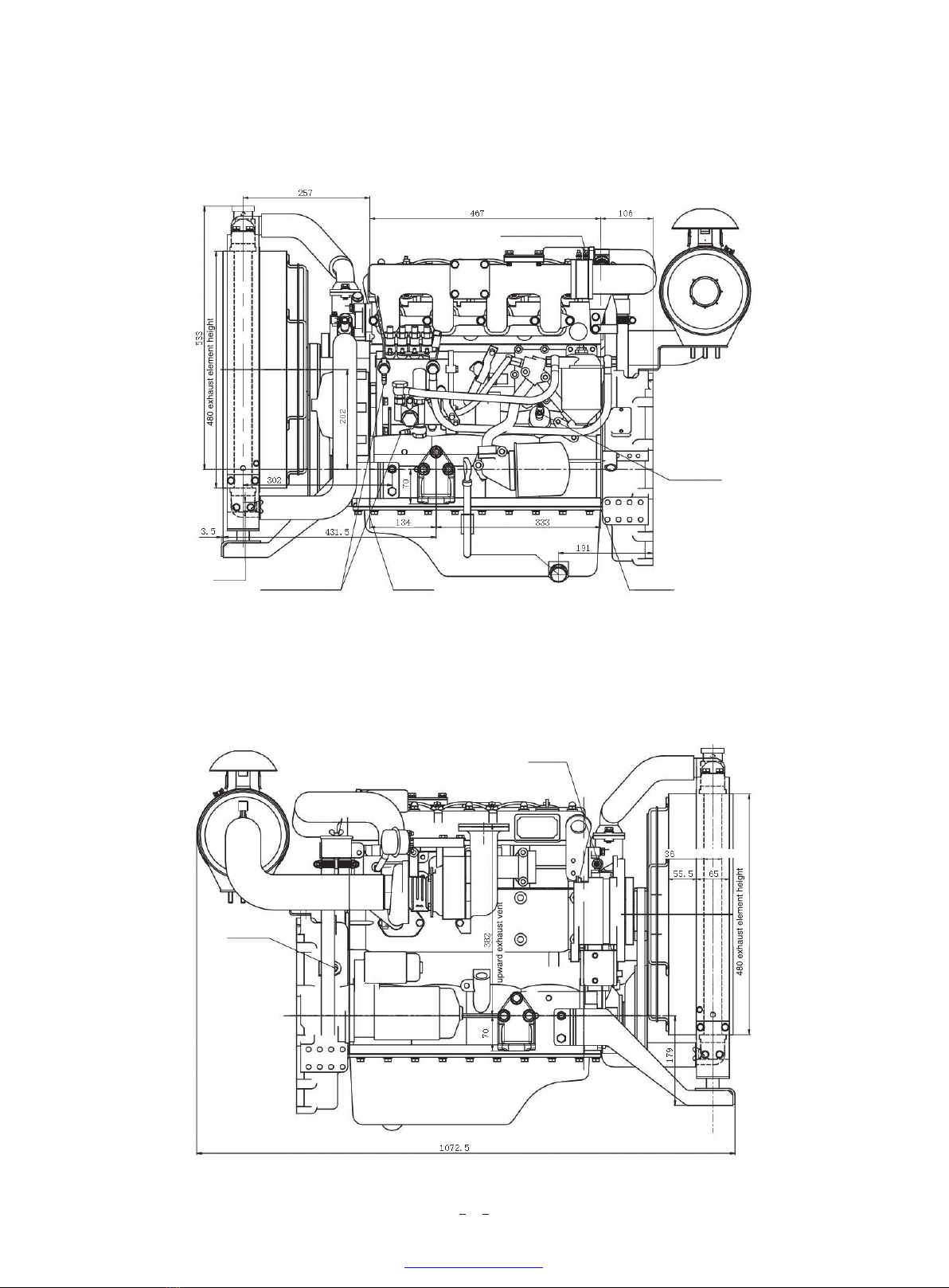

2、Outline Drawing of Diesel Engine

2.1 Outline drawings of 4DW81-23D, 4DW81-28D, 4DW91-29D and 4DW91-38D

fuel filter

observation

hole

oil pressure sensor

NPT1/4

NPT1/4

M20×1.5

oil filter

oil drainage plug screw

Φ8external diameter of fuel inletΦ8

external diameter of fuel return

M10×1

water drainage valve

speed sensor interface

M18×1.5

rear end surface

of engine block

water temperature

sensor interface

NPT3/8

alternator

respirator

(element thickness)

front end surface

of engine block

www.bezpeka-shop.com

11

2.2 Outline drawings of 4DW92-35D and 4DW92-42D

water temperature sensor

NPT3/8

speed sensor

element thickness

rear end surface

of engine block

front end surface

of engine block

binding post of air heater M5

external diameter of

fuel inlet and return vent Φ8

water drainage valve

M10×1

oil pressure sensor

NPT1/8

NPT1/4

oil drainage plug screw

M20×1.5

www.bezpeka-shop.com

This manual suits for next models

5

Table of contents

Other Bison Engine manuals