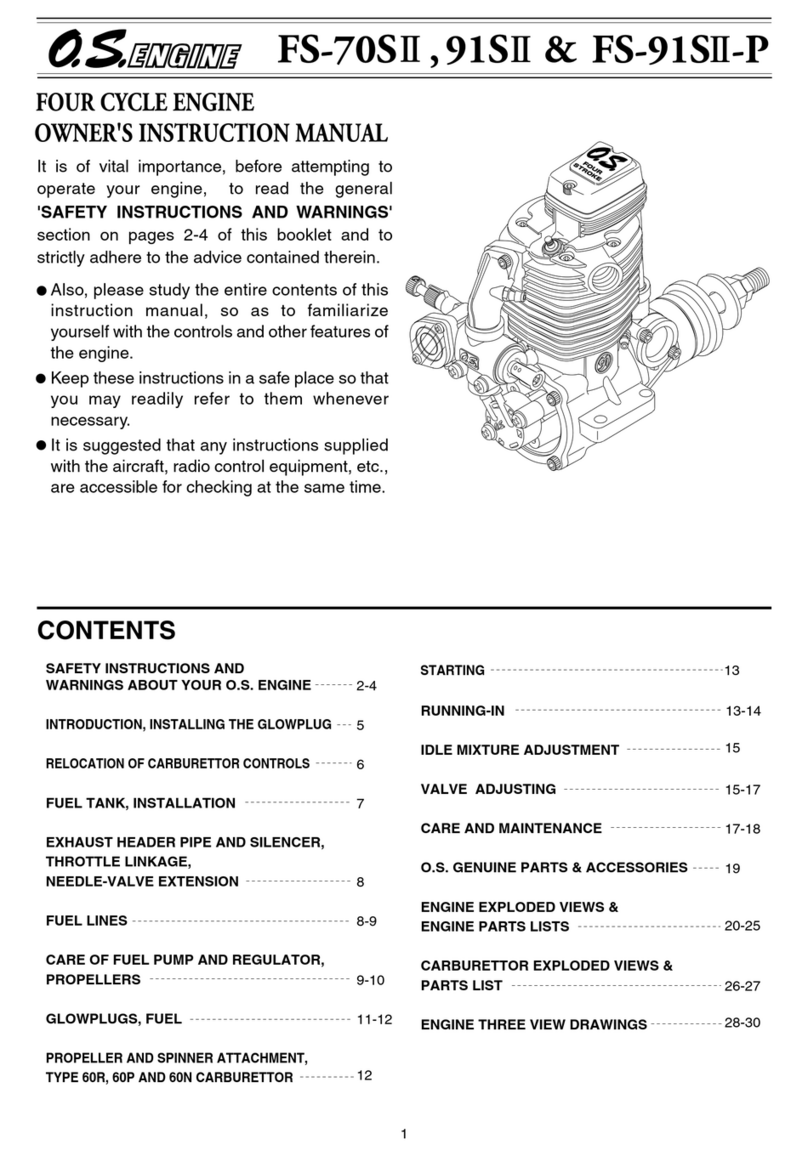

O.S. engine FS-70S User manual

Other O.S. engine Engine manuals

O.S. engine

O.S. engine Max-50SX-H Ring Setup guide

O.S. engine

O.S. engine MAX-25XZ User manual

O.S. engine

O.S. engine OMA-6030-220 Setup guide

O.S. engine

O.S. engine fs-70II Setup guide

O.S. engine

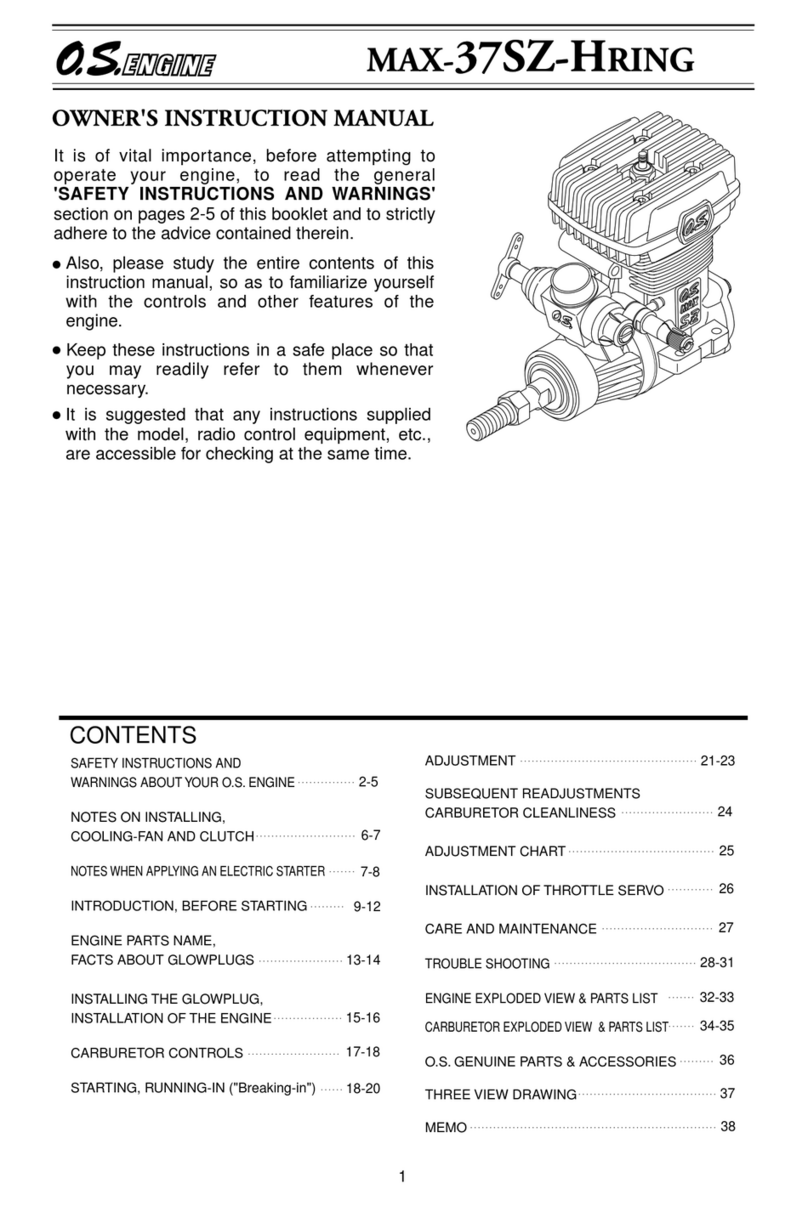

O.S. engine MaX-37SZ-HRING Setup guide

O.S. engine

O.S. engine FSA-72 Setup guide

O.S. engine

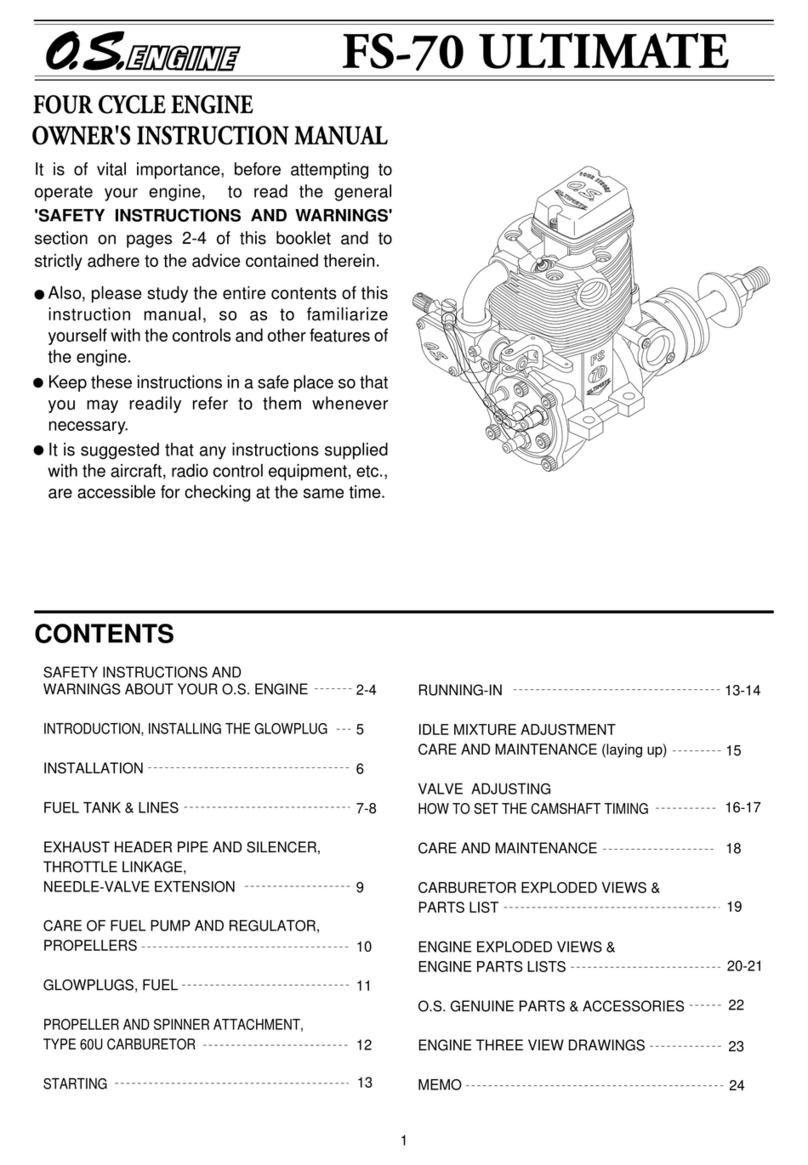

O.S. engine FS-70 Ultimate Setup guide

O.S. engine

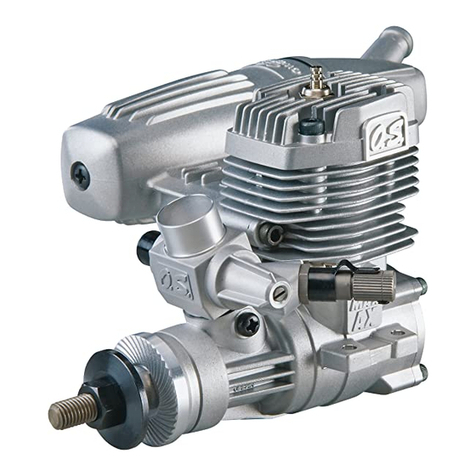

O.S. engine MAX-25AX & MAX-35AX User manual

O.S. engine

O.S. engine MAX-90FSR User manual

O.S. engine

O.S. engine MAX-12CV-R Setup guide

O.S. engine

O.S. engine O.S. Motor OMH-5825-520 Setup guide

O.S. engine

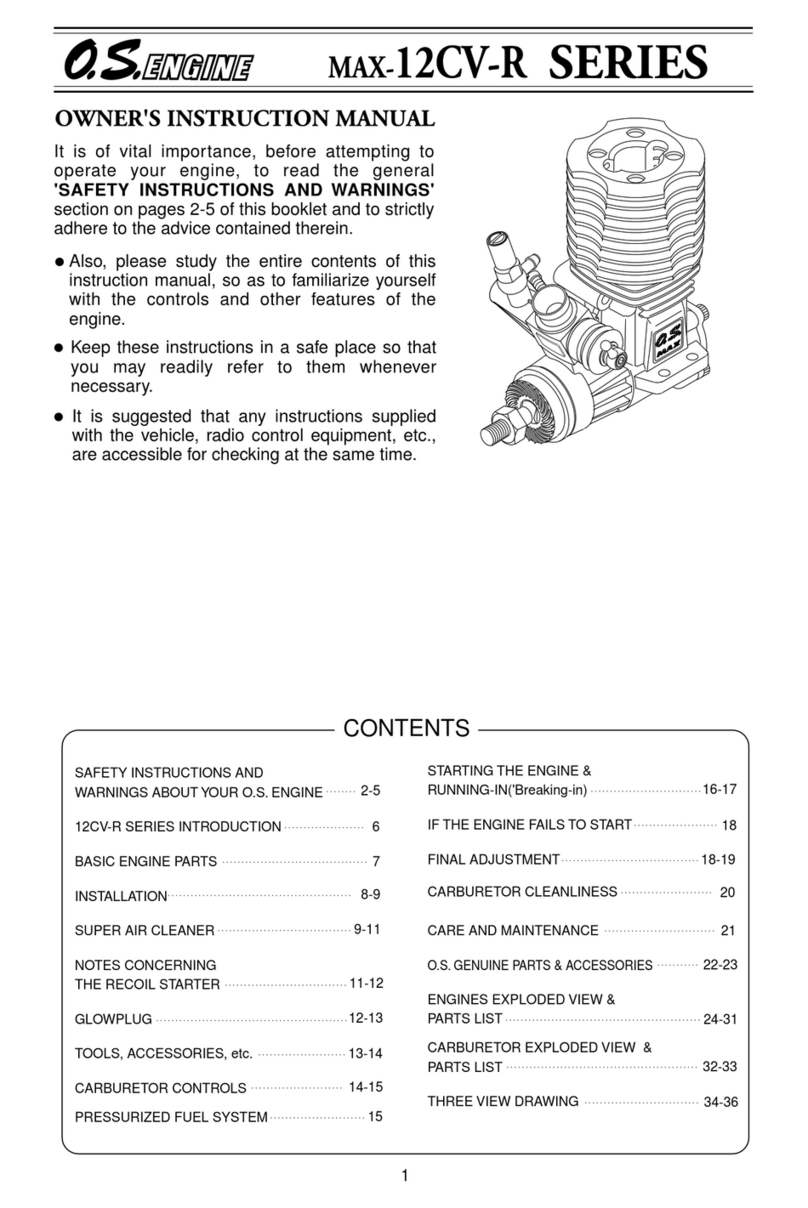

O.S. engine MAX-12CV Series Setup guide

O.S. engine

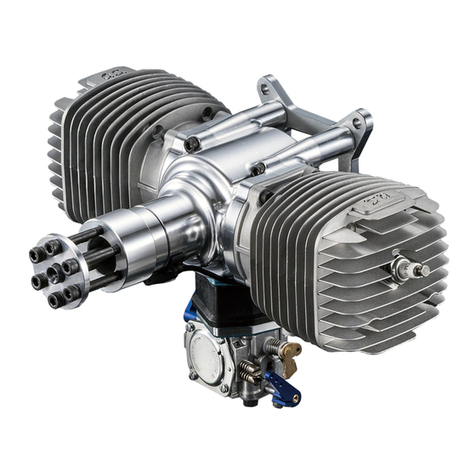

O.S. engine GT120THU User manual

O.S. engine

O.S. engine MAX-15CV-R Series User manual

O.S. engine

O.S. engine max 21 RZ-M User manual

O.S. engine

O.S. engine FS-200S Setup guide

O.S. engine

O.S. engine MAX-75AX-BE User manual

O.S. engine

O.S. engine MAX-50SX Setup guide

O.S. engine

O.S. engine GGT15 Setup guide

O.S. engine

O.S. engine GT120T User manual

Popular Engine manuals by other brands

Idex

Idex MICROPUMP EagleDrive DEMSE Installation, operation and warranty information

Desert Aircraft

Desert Aircraft DA200 owner's manual

Yamaha

Yamaha F150A Service manual

W&H

W&H EM-19 Instructions for use

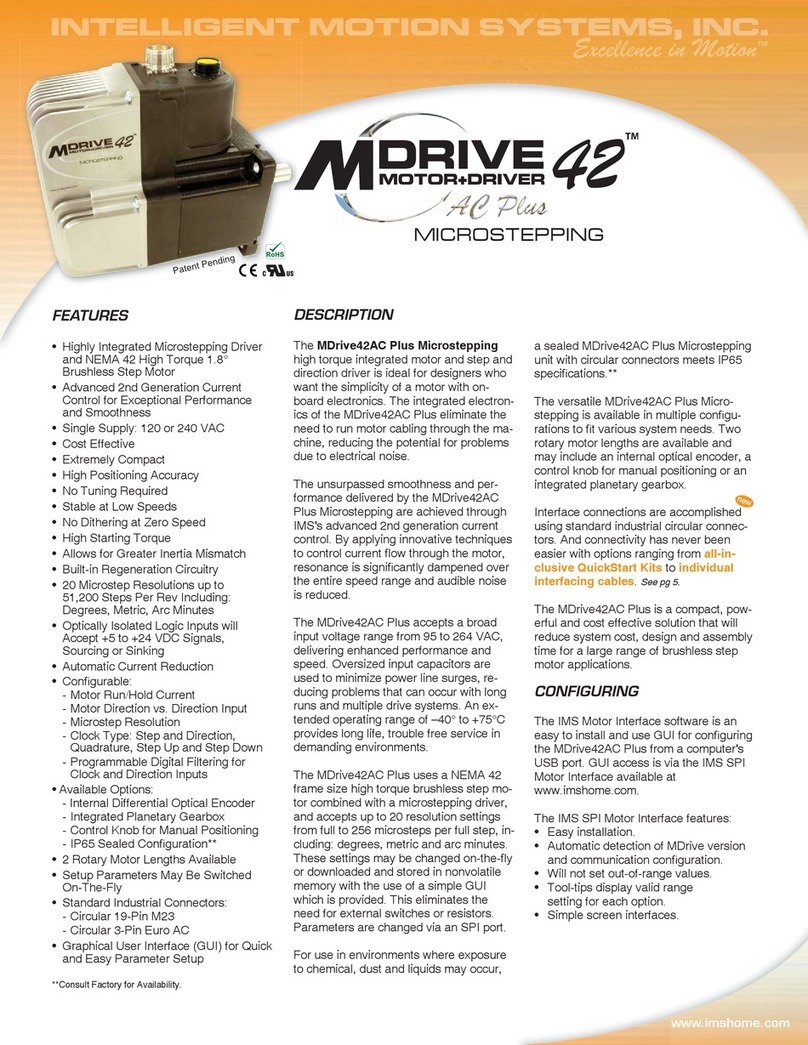

Intelligent Motion Systems

Intelligent Motion Systems MDrive42AC Plus Microstepping Product data

Perkins

Perkins 4008-30 SD8 Systems Operation, Testing and Adjustment