RUNNING-IN ("Breaking-in")

ADJUSTMENT

CARE AND MAINTENANCE

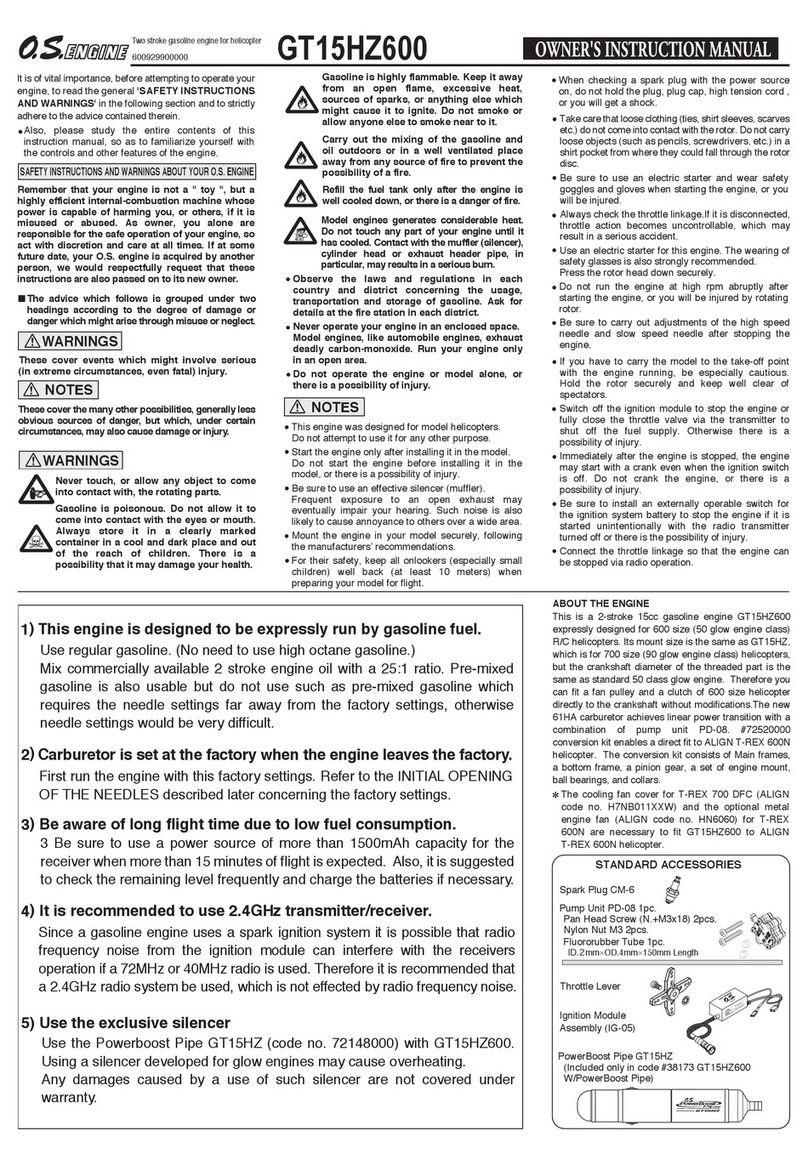

Please pay attention to the matters described

below to ensure that your engine serves you well

in regard to performance, reliability and long life.

As previously mentioned, it is vitally important to

avoid operating the engine in conditions where dust,

disturbed by the propeller, may be deposited on the

engine and enter its working parts.

Remember to keep your fuel container closed to

prevent foreign matter from contaminating the fuel.

Install a fuel filter to prevent foreign matter in the fuel

container from entering the fuel tank. O.S. Super

Filters (L) and (S) are available as optional extras.

Install an in-line fuel filter between the tank and

carburetor to prevent foreign matter in the tank from

entering the carburetor.

If these precautions are neglected, restriction of fuel

flow may cause the engine to cut out, or the fuel/air

mixture to become too lean causing the engine to

overheat.

Clean these filters periodically.

The use of modern high-performance alcohol based

model engine fuels, while promoting cooler running,

improved anti-detonation combustion and increased

power, have the disadvantage of causing corrosion

due to the acid by-products of combustion.

The use of nitromethane in the fuel can also

contribute to the problem.

Do not close the needle-valve and mixture control

valve too far as this will cause a lean setting and

over heating of the engine. This can, in turn, create

nitromethane oxide leading to internal rusting of the

engine. Always adjust the needlevalve slightly on the

rich side of peak rpm.

Do not leave unused fuel in the engine at the

conclusion of a day’s flying. Accepted practice is to

cut off the fuel supply while the engine is still running

at full throttle, then expel as much fuel residue as

possible by turning the engine over 5-10 seconds

with the electric starter.

Finally, inject some after-run oil through the glowplug

hole and turn the engine over several times by hand.

Stopping the engine

Fully pull down the throttle trim on the transmitter.

Starting

Preparation of starting

7.

8.

9.

In case the engine does not stop.

Hold the rotor head, and pinch the fuel line to stop the

fuel supply. If it still does not stop, pull off the fuel line

from the carburetor. It is necessary to readjust the

throttle linkage so that the carburetor rotor is fully

closed when the throttle stick and throttle trim on the

transmitter are fully pulled Down.

NOTE:

If the throttle response is poor or the engine stops

due to a temporarily over-rich mixture immediately

after the engine is started, pinch the fuel line for

one or two seconds until the engine r.p.m.

increase and the engine runs steadily.

SUBSEQUENT READJUSTMENTS

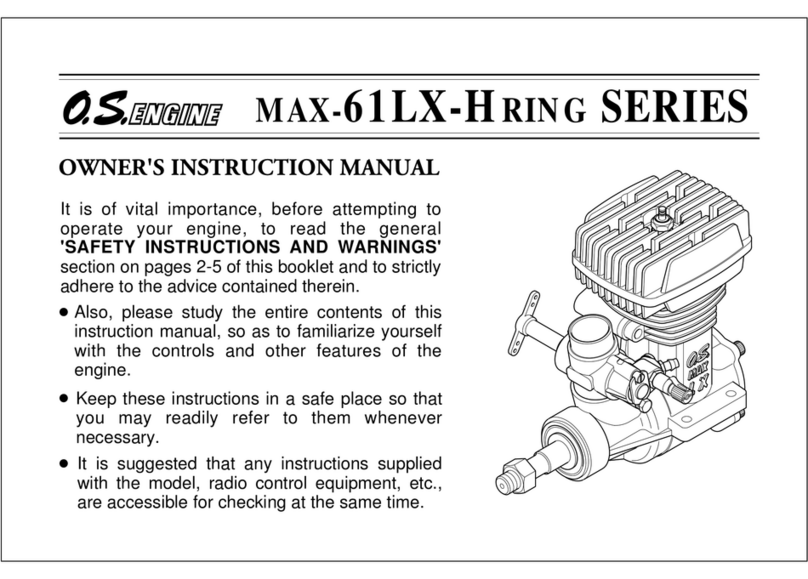

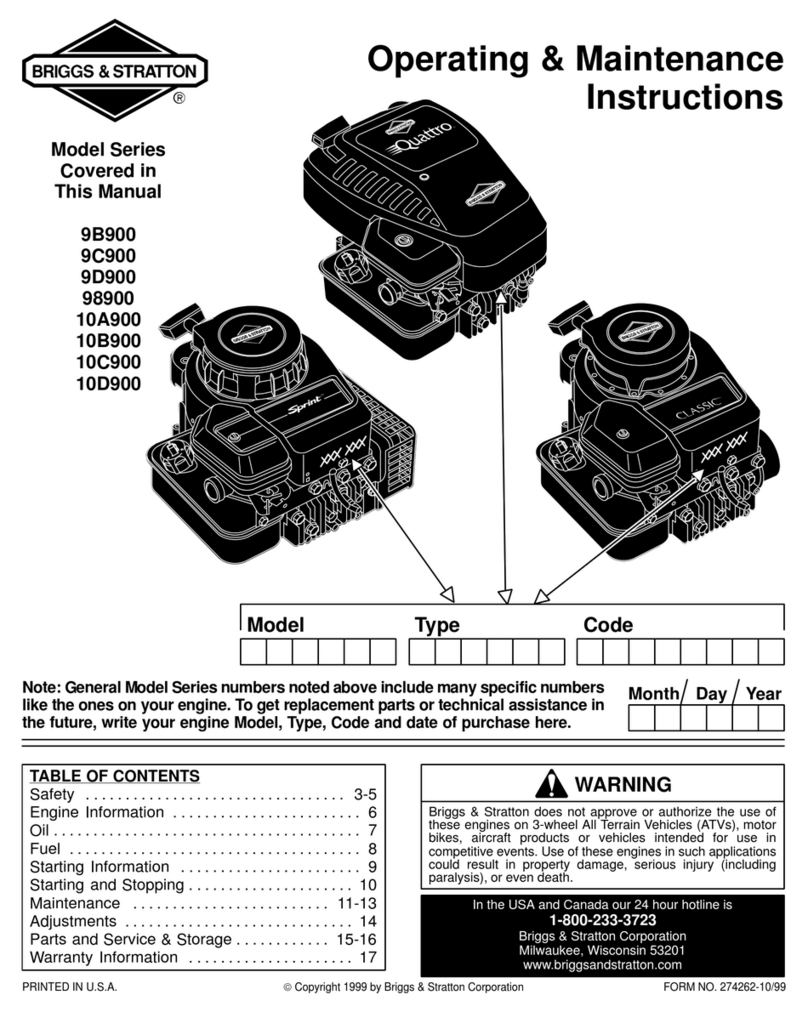

CARBURETOR CLEANLINESS

Remove this with

an 8mm wrench

Dirt and foreign matter

mostly accumulate here

6. Priming

5. Inserting the starter shaft

Insert the starting shaft into the shaft

cup securely.

Without energizing the glowplug,

open the throttle a little from the idle

position. Turn the engine over using

the starter until the fuel is seen to

reach the carburetor.

Connect the battery to the glowplug and start the

engine by applying the starter. When started, switch

off the starter and withdraw the starting shaft after

making sure the rotation of the starter shaft stops.

Hold the rotor head by hand so that

rotor cannot rotate when the engine

is Started. Also, steady the model

with a foot on the landing gear skid.

Make sure that the transmitter throttle

stick is at the fully closed position and

the throttle trim at center position, and

make sure that idle-up switch on the

transmitter is off.

All internal-combustion engines benefit, to some

degree, from extra care when they are run for the first

few times known as running-in or breaking-in.

This allows the working parts to mate together under

load at operating temperature.

However, because O.S. engines are made with the aid

of the finest modern precision machinely and from the

best and most suitable materrials, only a very short

and simple running-in procedure is required and can

be carried out with the engine installed in the model.

For the first few flights with a new engine i.e. while the

engine is being run-in set the needle-valve for a

slightly rich mixture not excessively rich as this may

result in poor throttle response and cause the engine

to stop.

About 1.5 turn open from the nomal setting will usually

suffice.

The following adjustments are approximately correct

when using a fuel containing 18-25% lubricant and

10-30% nitromethane.

Bear in mind that fuels containing relatively large

percentages of power-boosting nitromethane operate

at richer mixture settings than are needed for mild

fuels and will, therefore, require the Needle Valve to be

readjusted accordingly. The type and percentage of

lubricant used is also a factor here, as noted later in

these instructions.

This carburetor is not equipped with a throttle stop

screw. Instead, idle speed is adjusted by means of

the throttle trim lever on the transmitter.

This enables the full r.p.m. range, from idle to full

power, to be controlled by the throttle stick, and then

allows the engine to be stopped, from the

transmitter, by closing the throttle completely with

the trim lever.

As a safety measure, first check the transmitter

controls, including the throttle stick and trim lever

positions, and hold the main rotor securely before

starting the engine.

Warm the engine by allowing it to idle for about 30

seconds. If the engine stops, advance the throttle

trim lever slightly to increase the idle rpm. Then

open the throttle sufficiently to 'float' the model

above the ground.

Set up the throttle linkage as follows:

With the transmitter throttle trim lever fully retarded,

adjust the throttle servo linkage so that the throttle

rotor is (a) fully open when the transmitter throttle

stick is fully advanced and (b) fully

closed (i.e.

engine stopped) when the stick is fully

retarded. The

idle speed is then set by advancing the throttle trim

lever to the point where the engine runs, steadily

and reliably,at the desired idle speed.

lf, at this time, the engine is slow to pick up and produces

an excess of exhaust smoke, the mixture is too rich.

Correct this condition by turning the Mixture Control

Screw clockwise. lf the mixture is extremely rich,

engine rpm will become unstable : opening the throttle

will produce a great deal of smoke and rpm may drop

suddenly or the engine may stop.

This condition may also be initiated by an excessively

prolonged warming-up period.

lf, on the other hand, the mixture is too Iean, this wiIl

be indicated by a marked lack of exhaust smoke and

a tendency for the engine to cut out when the throttle

is opened. ln this case, turn the Mixture Control Screw

counter-clockwise to enrich the mixture.

Turn the Mixture Control Screw 5 degrees at a time.

Hover the model and actuate the throttle to observe

response over the medium speed range. lf the

engine smokes excessiveIy and throttle response is

poor, the mixture is too rich ; in which case, land the

model and turn the Needle Valve clockwise. Do not

close the NeedIe Valve too much, keeping it a little

on the rich side at this stage.

lf, on the other hand, hovering is not stable and

response to the throttIe is over-sensitive, or if the

engine tends to overheat, this indicates that the

mixture is too lean and should be corrected by

turning the Needle Valve counter-clockwise.

Having provisionally set the idle mixture, the next

step is to adjust the mixture for hovering flight.

When satisfactory hovering flight has been achieved,

land the modeI again and re-check the engine's idle

qualities.

Now adjust the Needle Valve to achieve the best

performance when the model is flying at full throttle.

lf, at full throttle, acceleration is poor, the exhaust

unduly smoky and the model fails to reach expected

straight line speed, the mixture is too rich and the

Needle Valve setting will need to be reduced. lf,

however, after smoothly acceIerating to satisfactory

high-speed straight and level flight, power is lost

when the model is puIled up into a climb, the mixture

is too lean. ln this case, land the model immediately

and readjust Needle Valve to a richer setting.

After about 10 seconds of idling, open the throttle to

'float' the model. lf the transition is smooth, the idle

mixture is O.K. If the symptoms of either rich or Iean

running are observed, readjust the Mixture Control

Screw accordingly.

For helicopters, good throttle response at medium r.p.m.

(e.g.hovering speeds) is most important, since this is a

power range widely used in helicopter flight. The

optimum fuel/air mixture strength at medium speeds is

dependent on obtaining balanced adjustment of both the

Needle Valve and the Mixture Control.

lf both controls are already at their optimum setting,

some modification to these settings may be necessary

to achieve satisfactory mid-range throttle response, but

such readjustments should onIy be made within the

range where idle reliability and high-speed performance

are not unduly compromised. Readjustments should

therefore be carried out as follows:

Now re-check hovering performance and, if necessary,

fine-tune the mixture for hovering flight.

lf the mid-range throttle response is not rapid and

positive (indicating a rich mid-range mixture), turn the

Needle Valve 2 or 3 clicks clockwise, or turn the Mixture

Control Screw 1-3 degrees cIockwise.

lf, on the other hand, the response to mid-range

throttle movement is too sensitive (indicating a lean

mid-range mixture), turn the Needle Valve 2 or 3 clicks

counter-clockwise or turn the Mixture Control Screw

1-3 degrees counter-clockwise.

Throttle response at hovering speeds is aIso affected by

the reIationship of the main rotor pitch angle to throttle

opening. If the optimum mid-range throttle response

cannot be obtained by the carburettor adjustments

described above, try adjusting the helicopter's pitch

control characteristics.

The correct functioning of the carburetor depends on

its small fuel orifices remaining clear. The minute

particles of foreign matter that are present in any fuel

can easily partially obstruct these orifices and upset

mixture strength so that engine performance becomes

erratic and unreliable. It is recommended that fuel is

passed through a filter when the tank is filled and that

a good in-line filter is installed between the fuel tank

and carburetor and, furthermore, that this filter is

frequently cleaned to remove foreign matter that

accumulates on the filter screen. Finally, occasionally

remove the needle-valve holder from the carburetor as

shown in Photo and extract any remaining foreign

matter that may have lodged in the location shown in

Photo, right.

Once the engine has been run-in and the carburetor

controls properly set up, it should be unnecessary to

alter the mixture settings, except to make minor

adjustments to the Needle Valve occasionally, to take

account of variations in climatic conditions.

The use of a different fuel, however, particularly one

containing more, or less, nitromethane and / or a

different type or proportion of lubricating oil, is likely to

call for some readjustment of the Needle-Valve.

Remember that, as a safety measure, it is advisable to

increase the Needle Valve opening by an extra

half-turn counter-clockwise, prior to establishing a new

setting. The same applies if the silencer type is

changed. A different silencer may alter the exhaust

pressure applied to the fuel feed and call for a revised

Needle-Valve setting.

The use of a different glowplug, or changes to the

mainrotor and its pitch angles may also require

compensating carburetor readjustments.