ABOUT THE ENGINE

STANDARD ACCESSORIES

Make sure that the propeller is well balanced. An

unbalanced propeller and/or spinner can cause serious

vibration which may weaken parts of the airframe or

affect the safety of the radio-controlled system.

Since the engine is intended to be started with an electric

starter, the addition of a spinner assembly for centering

the starter sleeve is desirable. Use a heavy-duty, well

balanced spinner either of metal or plastic.

Warning:

The choice of propeller depends on the design and

weight of the aircraft and the type of flying in which you

will be engaged. Determine the best size and type

after practical experimentation. As a starting point,

refer to the props listed in the accompanying table.

Slightly larger, or even slightly smaller, props than

those shown in the table may be used, but remember

that the propeller noise will increase, due to higher rpm

or if a larger-diameter / lower-pitched prop is used.

PROPELLERS

FUEL

Fuel Filter

BEFORE STARTING

It is recommended to install a good in-line filter between the

fuel tank and carburetor to prevent entry of foreign matter

into the carburetor.

To prevent the pickup from adhering to the tank wall

under suction and restricting fuel flow, slots may be filed I

the end of the weight. Alternatively, O.S. Non-Bubble

Weight is available as an optional extra.

O.S. Non-Bubble Weight

O.S. Super Filter (Fuel Can Filter)

Install a filter on the outlet tube of your refueling container to

prevent entry of foreign matter into fuel tank. O.S. ‘Super

Filters’ (large and small) are available as optional extras.

GlowPlug Igniter

Commercialy available handy glowplug heater in which

the glowplug battery and battery leads are integrated.

Fuel Pump

Alternatively, one of the purpose-made manual or

electric fuel pumps may be used to transfer fuel directly

from your fuel container to the fuel tank.

Electric Starter and Starter Battery

Required when starting the engine.

A fuel tank of approximately 350cc capacity is suggested.

This allows around 10-12 minutes flying time, dependent

upon the type of fuel used, the size of propeller and on

the amount of full-throttle to part-throttle operation

throughout the flight.

Fuel Tank

Never touch, or allow any object to come

into contact with, the rotating propeller

and do not crouch over the engine when

it is running.

Adjust the throttle linkage so that the engine stops

when the throttle stick and trim lever on the

transmitter are fully retarded. Alternatively, the

engine may be stopped by cutting off the fuel supply.

Never try to stop the engine physically.

Take care that loose clothing (ties, shirt sleeves,

scarves, etc.)do not come into contact with the

propeller. Do not carry loose objects (such as

pencils, screwdrivers, etc.) in a shirt pocket from

where they could fall through the propeller arc.

Do not start your engine in an area containing loose

gravel or sand. The propeller may throw such

material in your face and eyes and cause injury.

For their safety, keep all onlookers (especially small

children) well back (at least 20 feet or 6 meters) when

preparing your model for flight. If you have to carry the

model to the take-off point with the engine running, be

especially cautious. Keep the propeller pointed away

from you and walk well clear of spectators.

Warning! Immediately after a glowplug-ignition

engine has been run and is still warm, conditions

sometimes exist whereby it is just possible for the

engine to abruptly restart if the propeller is casually

flipped over compression WITHOUT the glowplug

battery being reconnected. Remember this if you

wish to avoid the risk of a painfully rapped knuckle!

Always check the tightness of the propeller nut and

retighten it, if necessary, before restarting the engine.

Also, check the tightness of all the screws and nuts

before restarting the engine.

If you install a spinner, make sure that it is a precision

made product and that the slots for the propeller blades

do not cut into the blade roots and weaken them.

Preferably, use an electric starter. The wearing of

safety glasses is also strongly recommended.

Discard any propeller which has become split,

cracked, nicked or otherwise rendered unsafe.

Never attempt to repair such a propeller: destroy it.

Do not modify a propeller in any way, unless you are

highly experienced in tuning propellers for specialized

competition work such as pylon-racing.

Take care that the glow plug clip or battery leads do

not come into contact with the propeller. Also check

the linkage to the throttle arm. A disconnected

linkage could also foul the propeller.

After starting the engine, carry out any needle-valve

readjustments from a safe position behind the

rotating propeller. Stop the engine before attempting

to make other adjustments to the carburetor.

This engine was designed for model aircraft. Do not

attempt to use it for any other purpose.

Mount the engine in your model securely, following

the manufacturers' recommendations, using appropri-

ate screws and locknuts.

Be sure to use the silencer (muffler) supplied with the

engine. Frequent exposure to an open exhaust may

eventually impair your hearing. Such noise is also

likely to cause annoyance to others over a wide area.

Install a top-quality propeller of the diameter and pitch

specified for the engine and aircraft. Locate the

propeller on the shaft so that the curved face of the

blades faces forward-i.e. in the direction of flight. Firmly

tighten the propeller nut, using the correct size wrench.

If you remove the glowplug from the engine and

check its condition by connecting the battery leads to

it, do not hold the plug with bare fingers.Use an

appropriate tool or a folded piece of cloth.

NOTES

Model engine fuel is poisonous. Do not

allow it to come into contact with the eyes

ormouth.Alwaysstoreitinaclearlymarked

container and out of the reach of children.

Model engine fuel is also highly flammable.

Keep it away from open flame, excessive

heat, sources of sparks, or anything else

which might ignite it. Do not smoke or allow

anyone else to smoke, near to it.

Model engines generate considerable

heat. Do not touch any part of your

engine until it has cooled. Contact with

the muffler (silencer), cylinder head or

exhaust header pipe, in particular, may

result in a serious burn.

A weakened or loose propeller may disintegrate or

be thrown off and, since propeller tip speeds with

powerful engines may exceed 600 feet(180 metres)

per second, it will be understood that such a

failure could result in serious injury, (see 'NOTES'

section relating to propeller safety).

Never operate your engine in an enclosed space.

Model engines, like automobile engines, exhaust

deadly carbon-monoxide. Run your engine only in

an open area.

It is of vital importance, before attempting to operate your

engine, to read the general 'SAFETY INSTRUCTIONS

AND WARNINGS' in the following section and to strictly

adhere to the advice contained therein.

Also, please study the entire contents of this

instruction manual, so as to familiarize yourself with

the controls and other features of the engine.

SAFETY INSTRUCTIONS AND WARNINGS ABOUT YOUR O.S. ENGINE

The advice which follows is grouped under two

headings according to the degree of damage or

danger which might arise through misuse or neglect.

WARNINGS

NOTES

These cover events which might involve serious

(in extreme circumstances, even fatal) injury.

These cover the many other possibilities, generally less

obvious sources of danger, but which, under certain

circumstances, may also cause damage or injury.

WARNINGS

Remember that your engine is not a " toy ", but a

highly efficient internal-combustion machine whose

power is capable of harming you, or others, if it is

misused. As owner, you, alone, are responsible for

the safe operation of your engine, so act with

discretion and care at all times. If at some future

date, your O.S. engine is acquired by another

person, we would respectfully request that these

instructions are also passed on to its new owner.

SIZE(DxP) 15x10-12, 16x8-10

SPINNER

MAX-120AXRING

Two versions are available, the one is without

silencer, extension adaptor and 90 degree adaptor

and the other is with all of them.

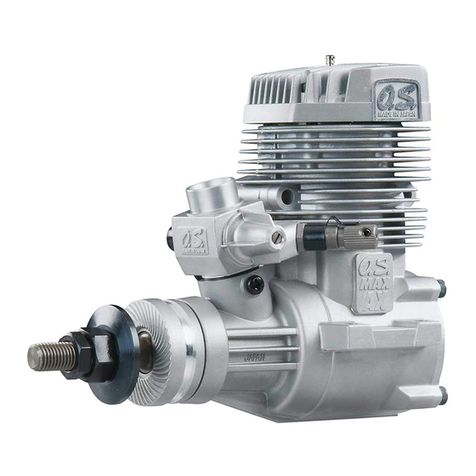

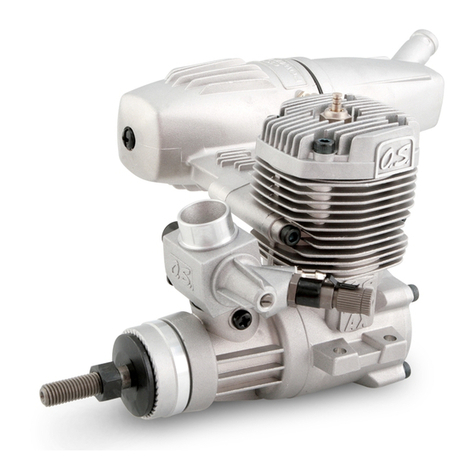

This is a high performance two stroke engine designed

for sport and scale models.

Crankcase and cylinder head are of aero-shape design

which give advantage of light weight, compact size.

The new 70D carburetor needlevalve assembly has

now been angled backward for safety.

New E-5020 silencer (POWER BOX) develops very

effective muffling. Also, the compact body enables it

to be fit with in most cowls.

Extension adaptor and 90 degree adaptor offer

various silencer installations.

Glow Plug No.8

E-5020 Silencer Extention Adapter

Needle Valve Extension Cable Set

Silencer Extention Adapter

Retaining Screw (M4x90 2pcs.)

E-5020 Silencer Assembly

Silencer Retaining Screw (M4x45 2pcs.)

E-5020 Silencer 90 Adapter

Silencer 90 Adapter Retaining

Screw (M4x20 2pcs.)

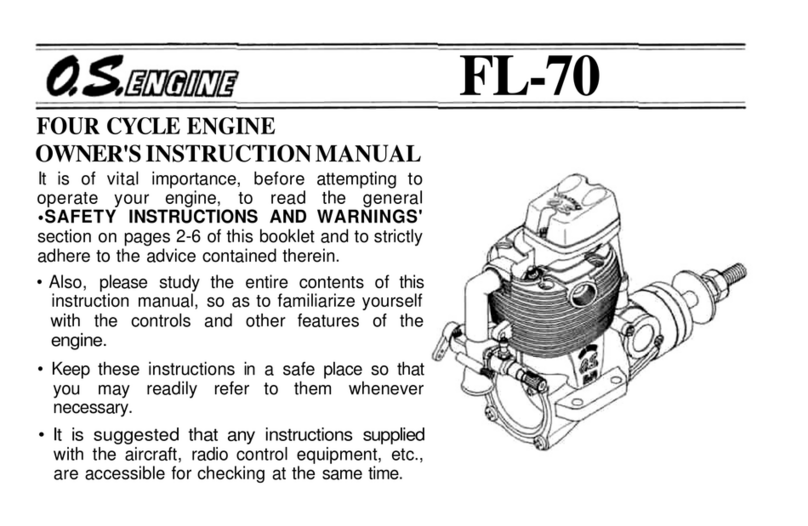

The 120AX should be operated on a methanol based fuel

containing not less than 18% (volumetric) castor oil, or a

top quality synthetic lubricant (or a mixture of both), plus

a small percentage (5-20%) of nitromethane for improved

flexibility and power. (The carburetor is adjusted a little on

the rich side at the factory for a fuel containing 20%

lubricant and 15% nitromethane.) Some commercial

fuels also contain coloring additives as an aid to fuel level

visibility. In some cases, these additives have indicated

slightly negative effects on the performance. We would

suggest that you use such fuels only if you are satisfied

that they do not adversely affect running qualities when

compared with familiar standard fuels.

When changing to a fuel brand or formula that is different

from the one to which you are accustomed, it is a wise

precaution to temporarily revert to in-flight running-in

procedures, until you are sure that the engine is running

entirely satisfactorily.

2 CYCLE ENGINE

600917300000