Oakdale Aircraft F35 Construction

Page 3

www.oakdaleaircraft.com

BILL OF MATERIALS:

Part

Number Qty Description

2000 1 F35 Molded Fuselage

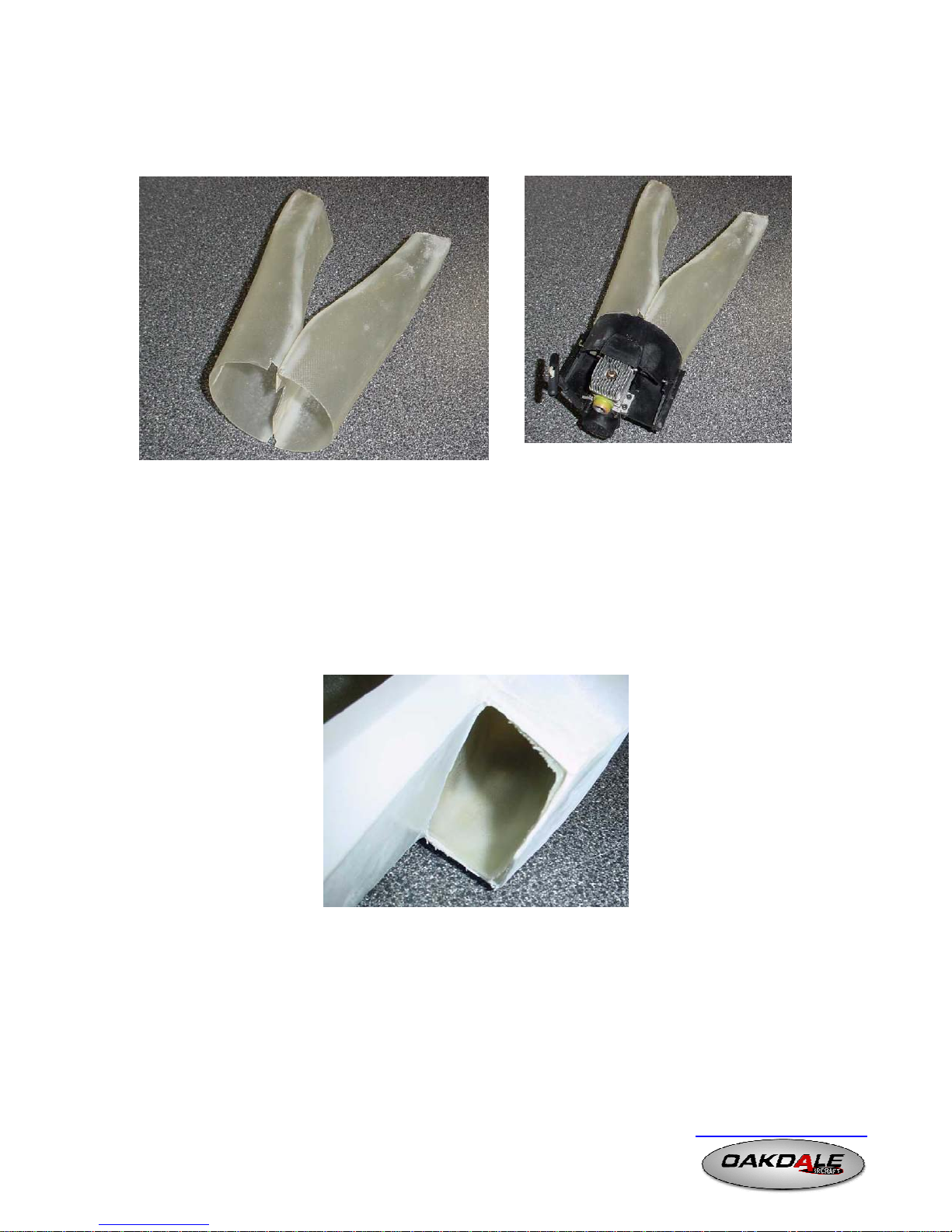

2001 1 Intake Ducting

2002 1 Exhaust Ducting

2005 1 Laser Cut Ply Set

2006 1 Laser Cut Formers

2010L 1 Foam Core, Wing, Left

2010R 1 Foam Core, Wing, Right

2011 1 Foam Core, Taileron

2012 1 Foam Core, Fin

2015 1 Vacuum Formed Clear Canopy

Hardware Pack

2021 1 Hinges (Robart)

2022 1 Wire, Main/Nose Gear-1/8"x36" (K&S)

2023 2 Main Wheels, 1-1/2” (Great Planes/Dubro)

2024 1 Nose Wheels, 1-1/4” (Great Planes/Dubro)

2025 1 Wheel Collar Set-1/8" (Dubro)

2026 8 ¼” x 1/8” Rare Earth Magnets

2027 2 Nose Wheel Steering Cable (ft) (Oakdale)

2029 4 6-32 wood screws (fan mounting) (Oakdale)

2030 1 Main Gear Straps (1/8") (Dubro)

2031 2 Pushrod (w/ clevis) (Dubro)

Balsa Pack

2040 10 1/16" x 3" x 36" Balsa Sheet

2041 1 1/8" x 3/8" x 36" Balsa Stick

2042 2 3/8" x 3/8" x 36" Balsa Stick

2043 1 1/2" x 1/2" x 36" Balsa Stick

2045 1 3/16” x 6” Spruce Dowel

2046 1 ½” x ½” x 12” Hardwood

Optional Glow Pack

2050 2 Fuel Tanks (Sullivan Oval)

2051 3 Fuel Tubing (ft) (Dubro)

2052 2 T-Fitting (Oakdale)

2053 1 Pushrod (w/ clevis) (Dubro)

2060G 1 F35 Instruction Manual

Note: Italic part numbers are included in the standard kit only