CONTENTS

1CHANGE LOG....................................................................................................................................................... 3

2ABOUT THIS DOCUMENT .................................................................................................................................... 4

3ABOUT THIS PRODUCT ........................................................................................................................................ 5

3.1 VERSIONS............................................................................................................................................................... 6

4SAFETY INSTRUCTIONS........................................................................................................................................ 7

4.1 GENERAL CONSIDERATIONS........................................................................................................................................ 7

4.2 ENVIRONMENTAL CONSIDERATIONS............................................................................................................................. 7

4.3 PERSONAL CONSIDERATIONS ...................................................................................................................................... 7

5INSTALLATION..................................................................................................................................................... 8

5.1 DEVICE INSTALLATION ............................................................................................................................................... 8

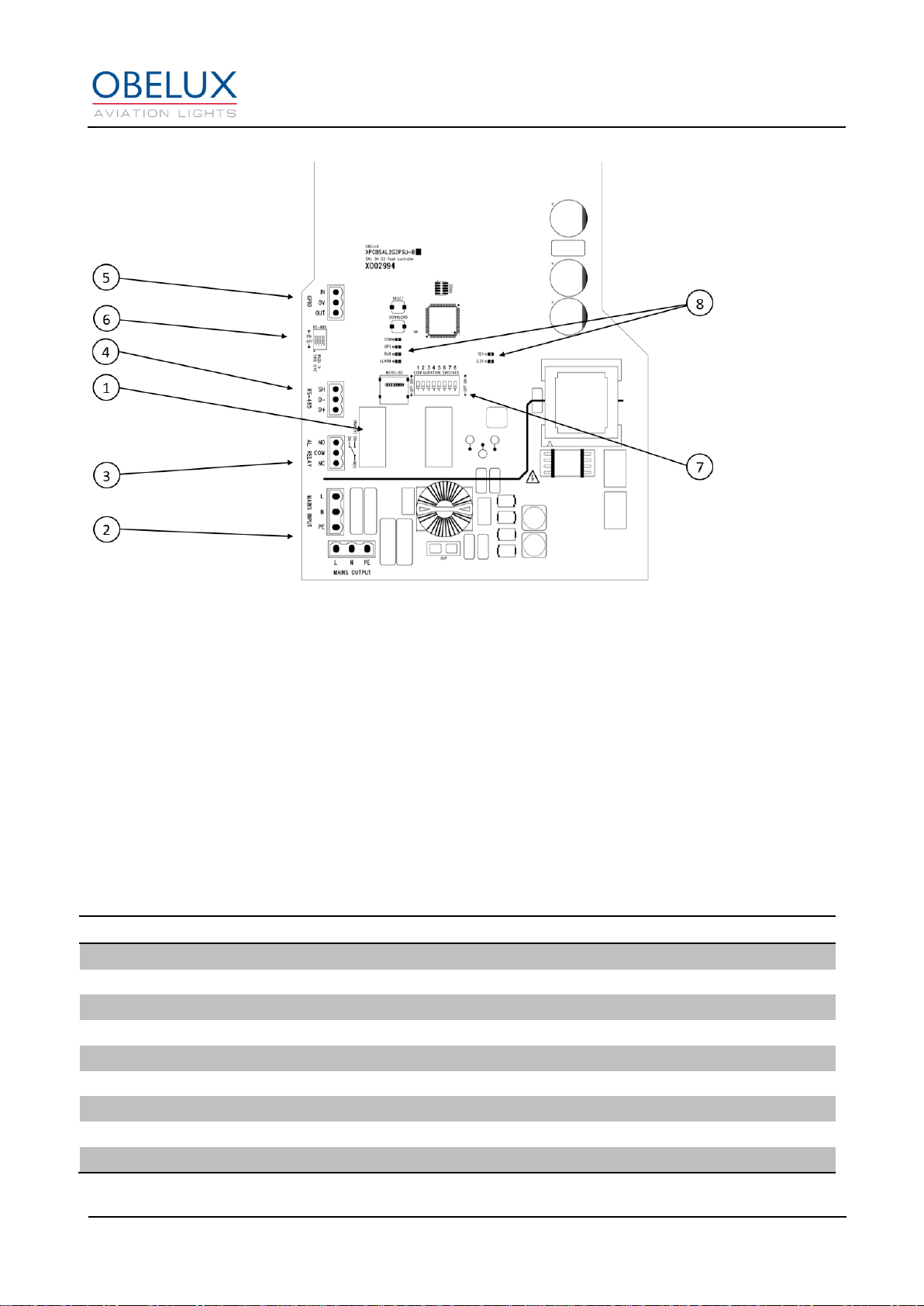

5.2 WIRING ................................................................................................................................................................. 8

5.2.1 Mains input (ACW versions and L864-MX-GA).......................................................................................... 11

5.2.2 Mains output (ACW versions) ................................................................................................................... 11

5.2.3 DC input (DC versions)............................................................................................................................... 12

5.2.4 DC output (DC versions) ............................................................................................................................ 12

5.2.5 Alarm Relay Output................................................................................................................................... 12

5.2.6 RS485 input (not available with L864-MX-GA).......................................................................................... 12

6CONFIGURATION ...............................................................................................................................................13

6.1 STAND-ALONE MODE.............................................................................................................................................. 14

6.2 MODBUS MODE .................................................................................................................................................... 16

6.3 TEST MODE........................................................................................................................................................... 17

6.4 L864-MX-GA CONFIGURATION .............................................................................................................................. 17

7OPERATION........................................................................................................................................................18

7.1 STAND-ALONE OPERATION....................................................................................................................................... 18

7.2 MODBUS OPERATION ............................................................................................................................................. 18

7.3 CAUSES FOR ALARM ............................................................................................................................................. 18

7.4 ONBOARD LEDS.................................................................................................................................................... 19

7.5 TROUBLESHOOTING................................................................................................................................................ 20

7.6 SPARE PARTS......................................................................................................................................................... 20

7.7 PACKAGING DETAILS ............................................................................................................................................... 20

8MAINTENANCE...................................................................................................................................................21

8.1 UPDATING DEVICE SOFTWARE................................................................................................................................... 21

8.2 REPLACING THE GLASS COVER ................................................................................................................................... 23

8.3 REPLACING MAIN CIRCUIT BOARD .............................................................................................................................. 25