Document UT-MT-0428 Page 5 of 35

Edition 11/03/2014 Supersedes edition 04/30/2012

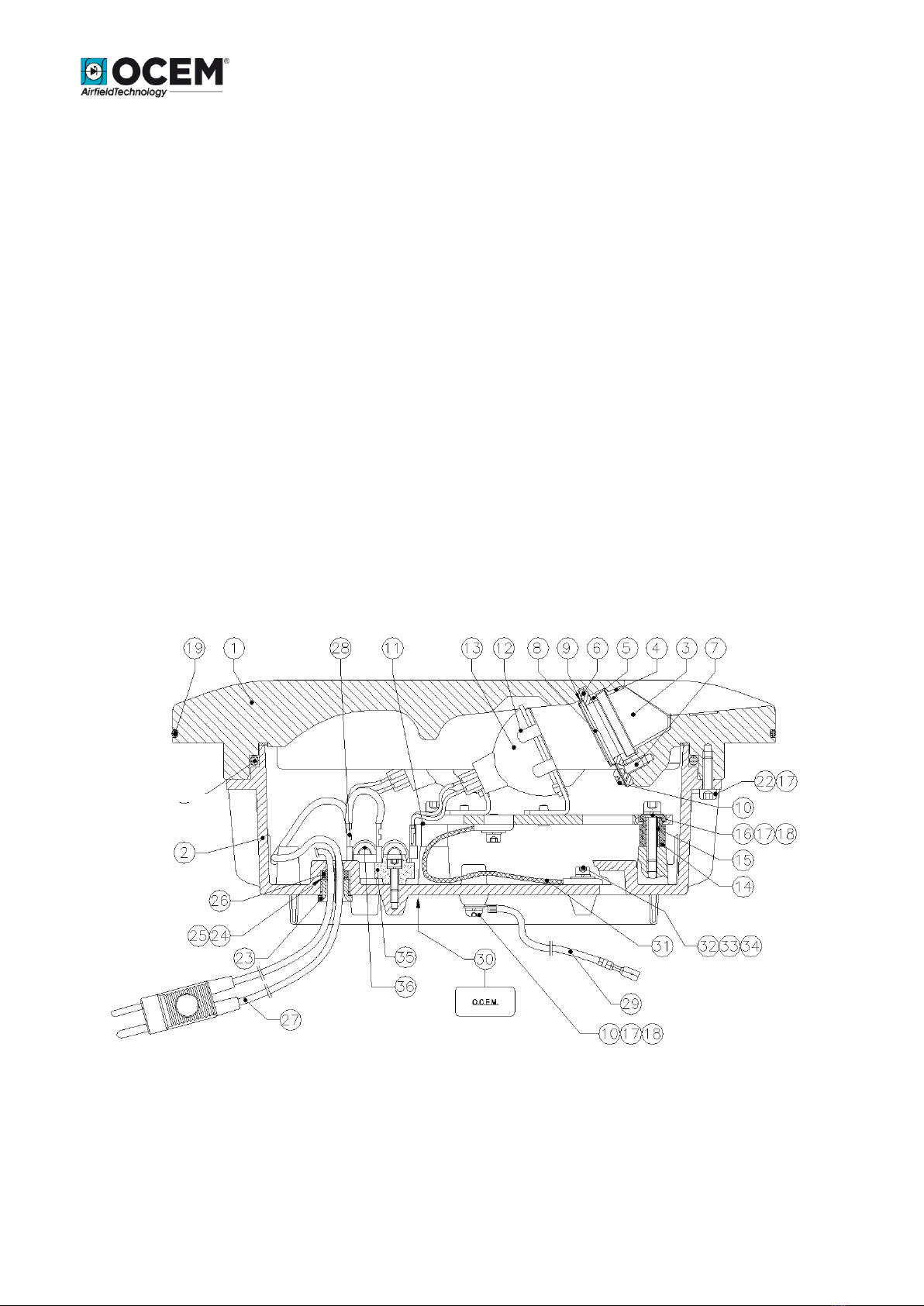

INSET RUNWAY EDGE LIGHT SLRE

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

INDEX

LIMITED PRODUCT WARRANTY......................................................................................................... 2

SAFETY INFORMATION...................................................................................................................... 2

EDITIONS ........................................................................................................................................... 4

REVISIONS.......................................................................................................................................... 4

LIST OF EFFECTIVE PAGES.................................................................................................................. 4

INDEX................................................................................................................................................. 5

INDEX OF FIGURES............................................................................................................................. 6

LIST OF ATTACHMENTS ..................................................................................................................... 7

1GENERAL.........................................................................................................................8

2MAIN FEATURES ............................................................................................................. 8

2.1 REMOVABLE LIGHT UNIT................................................................................................ 8

2.1.1 Dome..................................................................................................................... 8

2.1.2 Optical Assembly................................................................................................... 9

2.1.3 Lower Cover .......................................................................................................... 9

2.2 SHALLOW BASE ............................................................................................................ 16

3INSTALLATION .............................................................................................................. 17

3.1 Pavement Boring and Sawcutting ................................................................................ 17

3.1.1 Scheme of Light Configuration ........................................................................... 18

3.2 INSTALLING THE SHALLOW BASE ................................................................................. 19

3.3 INSTALLING THE LIGHT UNIT ON L-868 BASE, SIZE B ................................................... 23

3.4 SECONDARY WIRING .................................................................................................... 24

4MAINTENANCE ............................................................................................................. 25

4.1 MAINTENANCE PROGRAM........................................................................................... 25

4.1.1 Periodical Checks ................................................................................................ 25

4.1.2 Snowplow Operations......................................................................................... 26

4.2 REMOVING AND OPENING THE LIGHT UNIT FROM THE BASE .................................... 26

4.2.1 Removing the fixture .......................................................................................... 26

4.2.2 Opening the fixture............................................................................................. 26

4.2.3 Closing the fixture............................................................................................... 26

4.2.4 Leakage test ........................................................................................................ 27

4.2.5 Reinstalling the fixture........................................................................................ 27

4.3 PRIMS CLEANING.......................................................................................................... 28

4.3.1 Prism outside cleaning........................................................................................ 28

4.3.2 Prism inside cleaning .......................................................................................... 28

4.4 PRISM REPLACEMENT .................................................................................................. 28

4.4.1 Removing the Prism ............................................................................................ 29

4.4.2 Installing the New Prism ..................................................................................... 29

4.5 FILTER REPLACEMENT .................................................................................................. 29