3

Important information on the safe installation and operation of this

product. Read this information before operating the product. For your

personal safety, read these instructions. Do not operate the product

if you do not understand how to use it safely. Save these instructions

for future reference.

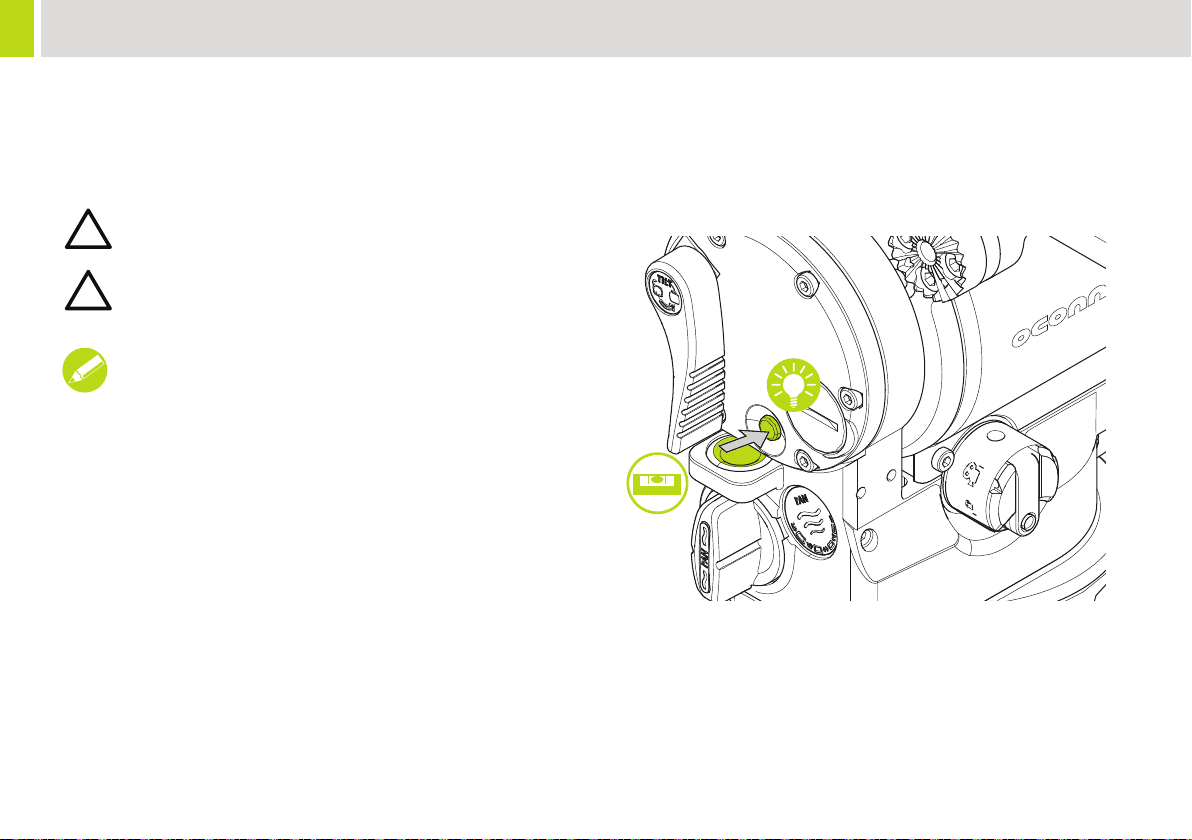

Warning Symbols Used in These Instructions

Safety cautions are included in these instructions. These safety

avoid possible damage to the product

Health and Safety

!

WARNING!

warning triangle symbol.

Where there is a risk of damage to the product,

associated equipment, process or surroundings,

comments appear supported by the word ‘CAUTION’.

!

WARNING! Risk of personal injury or injury to

others. All personnel must be fully trained and

adhere to correct manual handling techniques and

Health & Safety regulations. It is the responsibility

of the local organisation to enforce safe working

practices at all times.

Mounting and Installation

WARNING!

WARNING!

extending tripod legs.

WARNING! Risk of nger entrapment.

head to a tripod that cannot support the combined mass of

the head and its full payload.

WARNING! Toppling hazard. Do not leave unattended.

Keep out of reach of children.

WARNING! The product must always be secured.

CAUTION! Always lock the vertical and horizontal brakes

when the camera is mounted but not in use or when

CAUTION! Hold the camera securely when mounting

CAUTION! Always hold the pan bar when making

head.

CAUTION! Only attach camera accessories to the pan

bar. Do not attach heavy items to the pan bar.

CAUTION! Always remove the camera before

transporting.

WARNING!

payload the tilt lock must be engaged.

Maintenance

WARNING!

accessories, the carrying out of non-approved alterations

of the product. It may also invalidate the terms and

conditions of the product warranty.

Caution! When replacing the battery, use only the same

or an equivalent type of battery recommended for use with

the product.

Safety / About This Guide