7

Contents

Preface ...............................2

Features and benefits of your new 120EX . . . . . . . . . 2

The EX-Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Other Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety - Read This First . . . . . . . . . . . . . . . . . . 4

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . 5

Further Information . . . . . . . . . . . . . . . . . . . . . 6

Contents..............................7

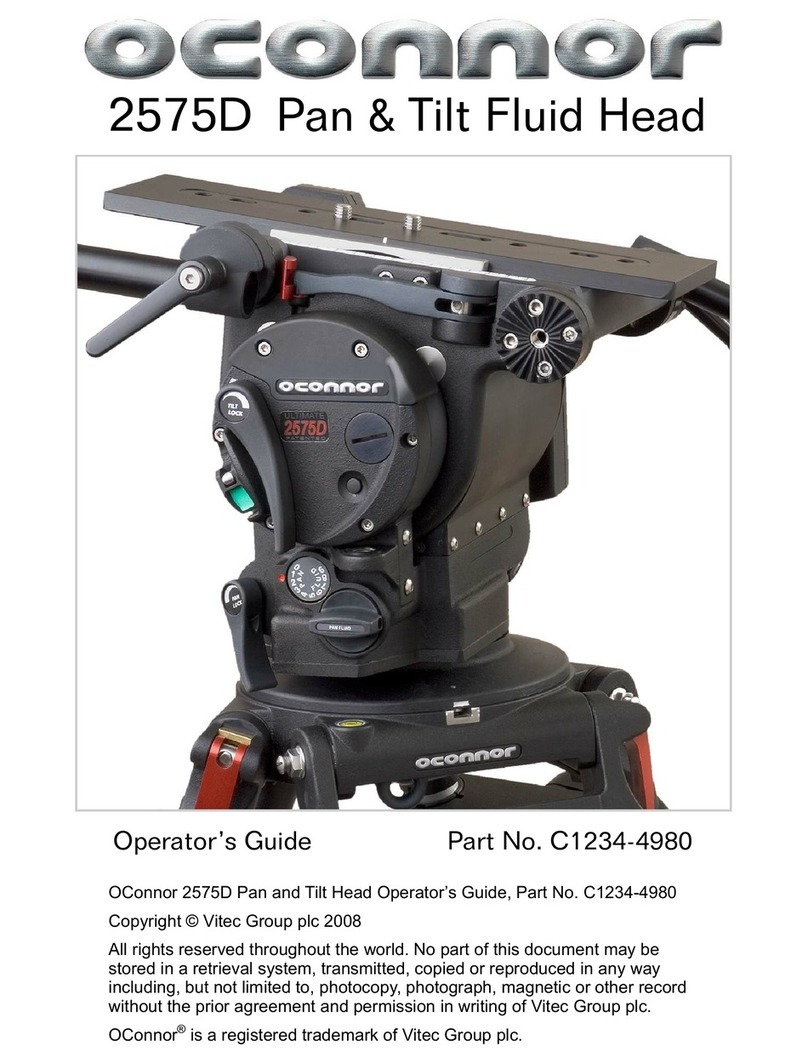

Introduction ...........................9

Extended Capacity Balance . . . . . . . . . . . . . . . . . . . 10

Digital Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Ultra Smooth Fluid Drag . . . . . . . . . . . . . . . . . . . . . . 10

Pan And Tilt Locks . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Tilt Lock Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Illuminated Bubble Level . . . . . . . . . . . . . . . . . . . . . . 11

Handle Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Camera Mounting Platform . . . . . . . . . . . . . . . . . . . . 11

Mitchell Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operation ............................12

Installing The Head . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Handles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Eyepiece Leveler . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Mounting A Camera . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Balancing The Head . . . . . . . . . . . . . . . . . . . . . . . . . 14

Fore And Aft Balance . . . . . . . . . . . . . . . . . . . . . . . 14

Payload Weight And C of G Height Adjustment. . . . . 16

Locking The Platform. . . . . . . . . . . . . . . . . . . . . . . . . 16

Pan And Tilt Locks . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Pan And Tilt Fluid Drag . . . . . . . . . . . . . . . . . . . . . . . 17

The Balance Display . . . . . . . . . . . . . . . . . . . . . . . . . 17

Low Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Operator's Guide - OConnor 120EX Pan and Tilt Head

www.ocon.com OConnor Engineering