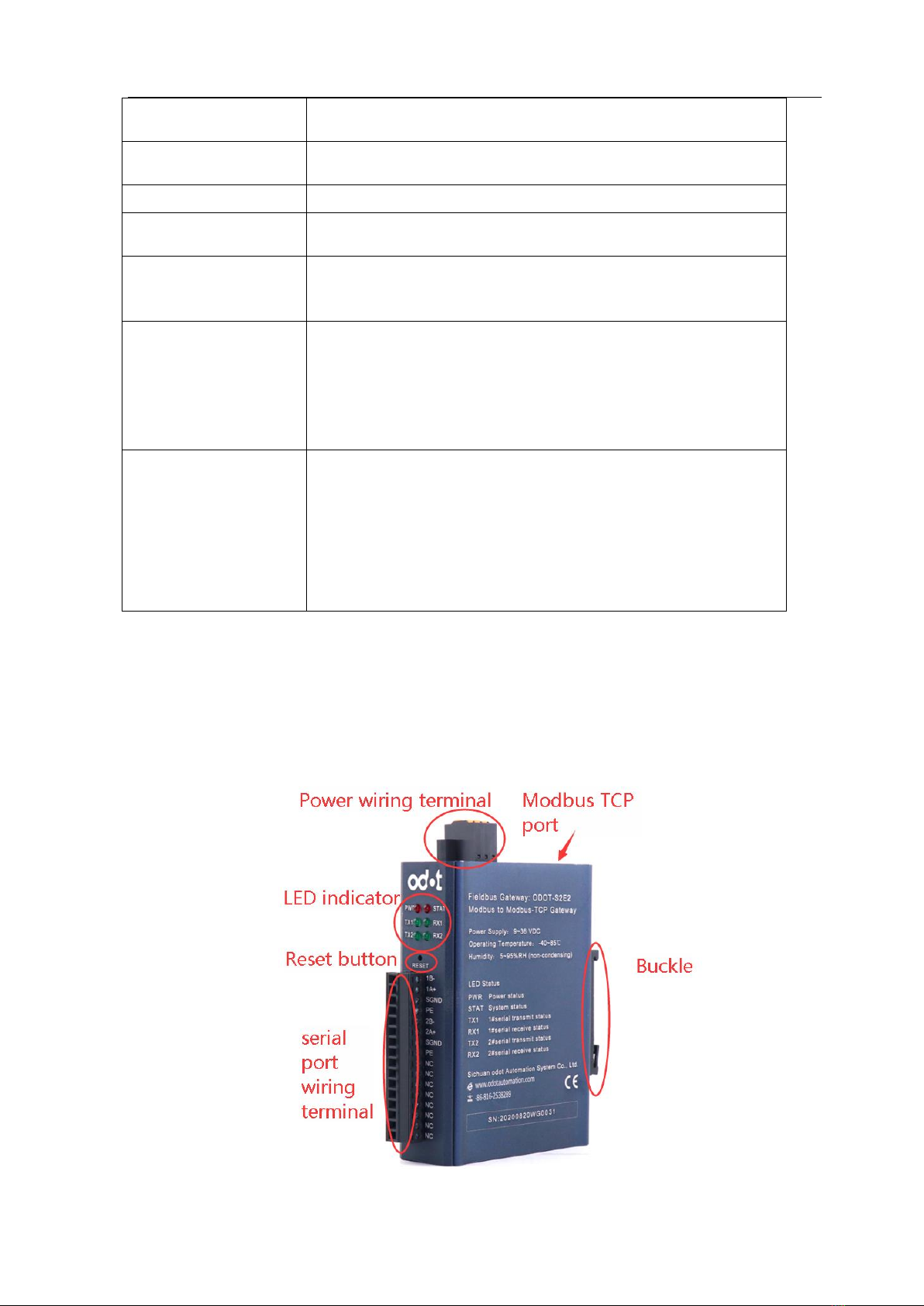

1. Product Overview

1.1 Product Functions

This product is a Modbus RTU/ASCII to Modbus TCP protocol converter developed

by Sichuan ODOT Automation System Co., Ltd based on market demand and years of

experience.

All slave devices that have RS485/RS422 interfaces and support Modbus RTU/ASCII

can connect to the Modbus TCP network through this gateway and communicate with TCP

clients. So as to realize the connection of low-speed serial devices to the high-speed

Ethernet to realize high-speed data transmission. The gateway has two different working

modes, "transparent" and "mapping", which can achieve maximum system compatibility.

1.2 Functional Characteristics

◆9-36V wide voltage input, anti-reverse connection protection. DC-DC isolated

power supply, 3000V isolation voltage.

◆2KV network port isolation protection, 10M/100Mbps rate adaptive, automatic

MDI/MDIX flip.

◆Small size, only 30mm thickness, saving installation space.

◆Support address mapping mode to realize fast response to TCP client request.

◆Support up to 5 TCP client access.

◆The mapping mode supports function codes:

0x01,0x02,0x03,0x04,0x05,0x06,0x0F,0x10.

◆The transparent transmission mode supports all public function codes and custom

function codes.

◆6KB large data buffer area, larger data transfer volume.

◆RS485 dual serial port refreshes in real time, with short scanning period and strong

load capacity.

◆The master and slave modes of RTU and ASCII are optional, which is highly

adaptable.

◆The watchdog can be enabled and the watchdog time can be set.