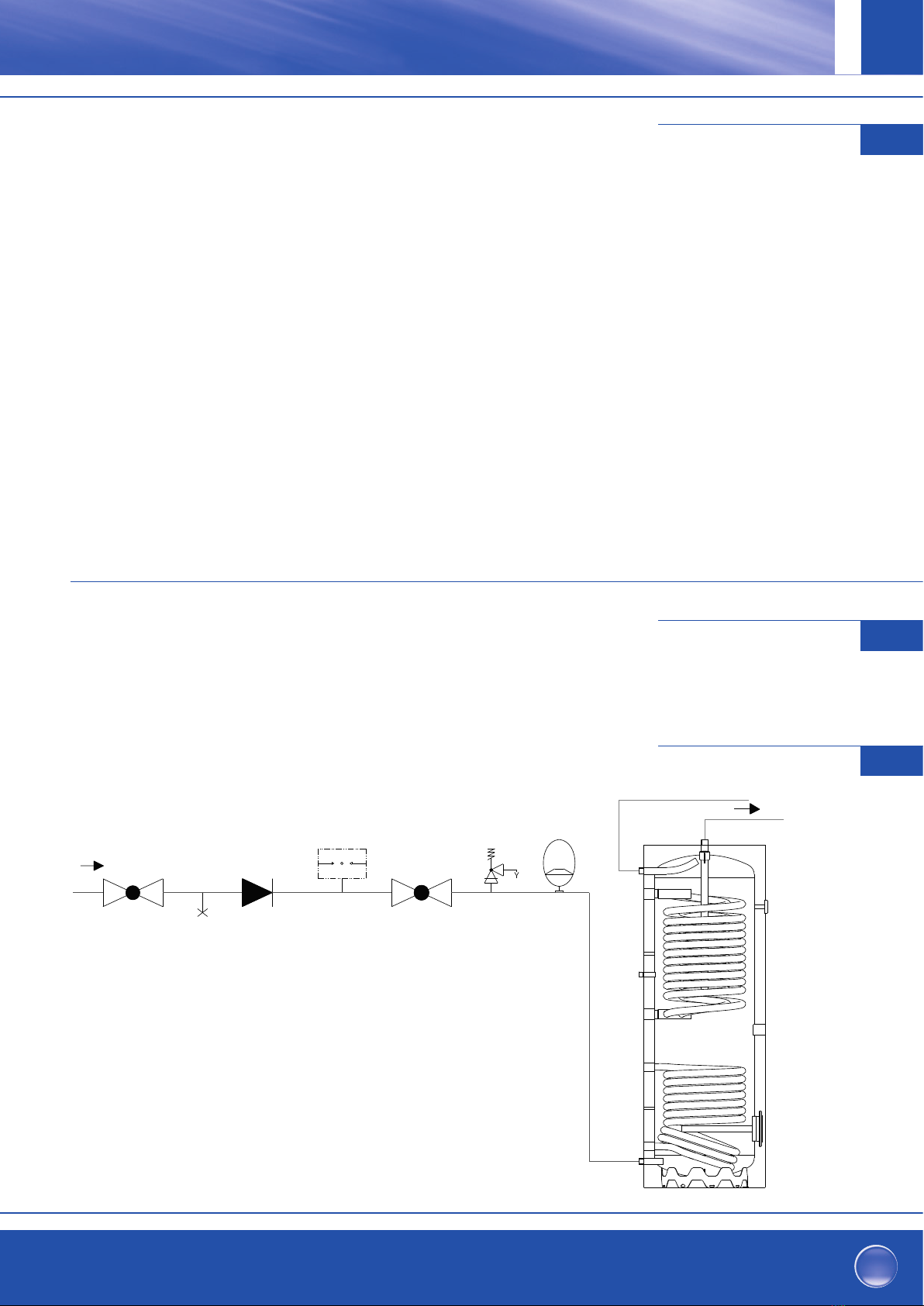

All storage tanks may only be used in closed systems. All connections are to be made

pressurised. Connections that are not required must be sealed. In order to minimise

heat losses, all lines should be insulated.

The storage tank is to be installed in such a way that it can be drained without

dismantling.

IMPORTANT: If a smooth-pipe heat exchanger is not required, it has to be sealed to

prevent the ingress of oxygen. Otherwise, due to the formation of condensing water

in conjunction with oxygen, this might lead to corrosion.

IMPORTANT: The smooth-pipe heat exchangers must not be locked on both ends if filled,

because an overpressure might otherwise occur.

IMPORTANT: Before commissioning / heating the storage tank via smooth-pipe heat

exchangers or screw-in immersion heaters, the tank must be completely filled with

drinking water. Otherwise, damages at the enamel are possible.

6

Connection3.1

Mixed installations3.2 According to technical rules, an appropriate electrical separation of the conductive

connection between the different materials has to be provided for mixed installations.

With the smooth-pipe heat exchangers flowed through by heating water, an electrical

separation in the flow and return line has to be made additionally in order to prevent

a short circuit via the mandatory grounding of the line.

Pressure shocks /

water hammers

3.3 When installing fast-closing shut-off and water-tapping valves (solenoid valves, ball

valves, single-lever mixers), it might come to short-term pressure shocks in drinking

water installations becoming noticable in the form of disturbing noises and eventually

leading to wear and break of pipes and storage tanks. When using such components,

appropriate water hammer dampers are to be provided. We assume no liability for

damages caused by pressure shocks and water hammers.

Commissioning3.4 Commissioning the storage tank is performed in the following steps:

• filling the storage tank

• opening the tapping points until the water streams out

• setting the safety valve

• heating up the storage tank after complete filling

IMPORTANT: All pre-assembled connections (e.g magnesium protective anodes and

service hatch) have to be checked for tightness before commissioning. After the first

heating up, all connections must be checked for correct seat or have to be retightened

if necessary. We assume no liability for damages caused by water.

IMPORTANT: For an optimal insulating effect, there must not be any condensing humidity

within the insulation. A damp insulation can be dried by lifting the top storage tank cover

temporarily during active operation.

Enamelled domestic water storage tanks

GB