2

Operating Instructions and Parts Manual 26100, 26101, 26102, 26103, 26104, 26105 and 26106

3/17

2017 OEMTOOLS™

AIR COMPRESSOR

IMPORTANT SAFETY INSTRUCTIONS

Save these instructions.

Improper operation or maintenance of this product

could result in serious injury and property damage.

Read and understand all warnings and operation

instructions before using this compressor.

1. Only persons familiar with these rules of safe

operation should use the air compressor.

2. Read the instruction manual carefully before

attempting to assemble, disassemble or operate

your system. Be thoroughly familiar with the

controls and the proper use of the equipment.

3. Review and understand all safety instructions and

operating procedures in this manual.

4. Review the maintenance methods for this compressor

(See “Maintaining Your Compressor” section).

5. Inspect your work area. Keep work area clean and

well lit.

6. Cluttered areas and benches invite accidents.

Floors must not be slippery from wax or dust.

7. Operate compressor in a well-ventilated area free

from flammable liquids and vapors.

8. Operate compressor in a ventilated area so that

compressor may be properly cooled and the

surrounding air temperature will not be more than

100°F.

9. Never use a compressor in a wet environment.

10.Protect material lines and air lines from damage or

puncture. Keep hose and wires away from sharp

objects, chemical spills, oil, solvents and wet floors.

11. A minimum clearance of 18 inches between the

compressor and a wall is required because objects

could obstruct airflow.

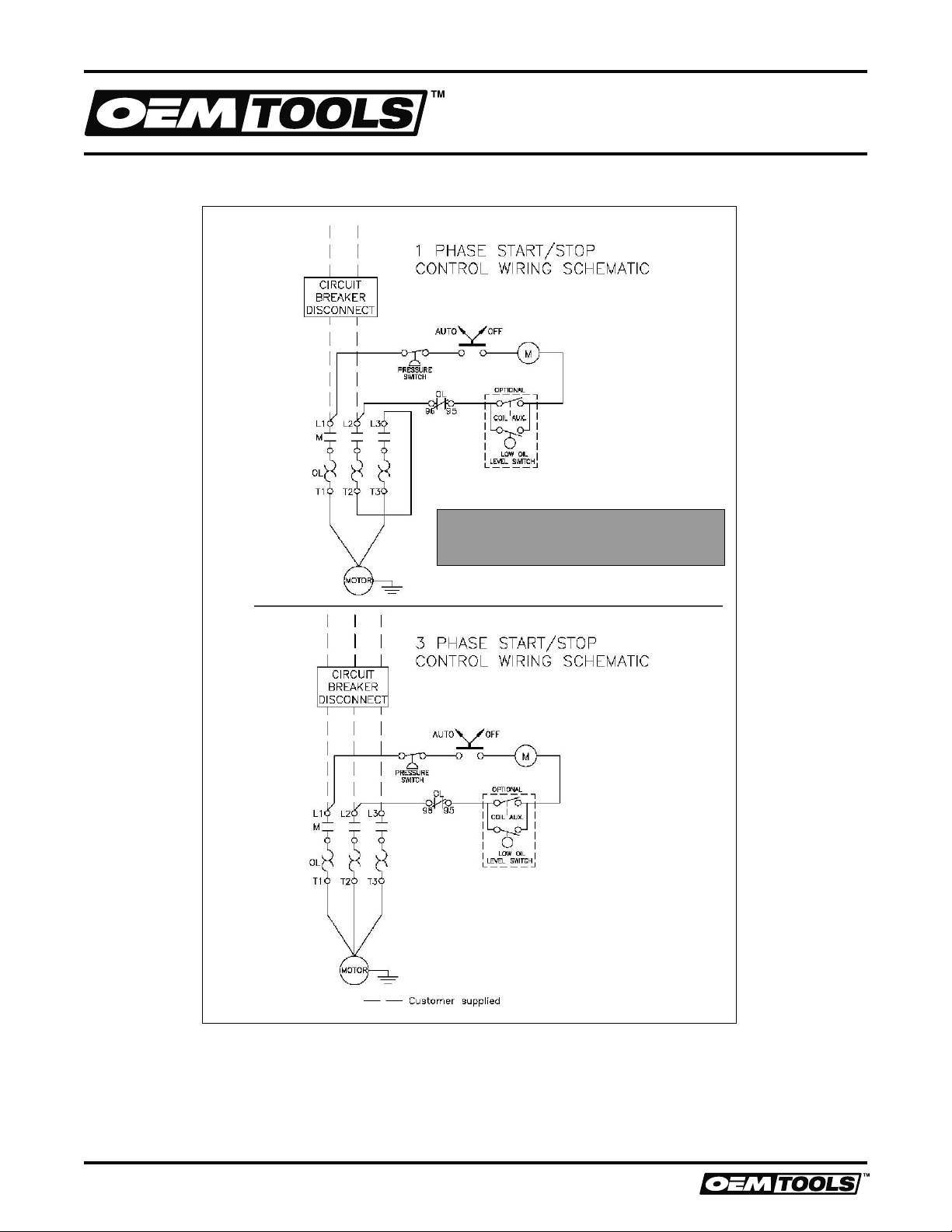

12.The compressor should be located where it can be

directly wired to a circuit breaker. The compressor

should be wired by a qualified electrician.

13.Never store flammable liquids or gases in the

vicinity of an operating compressor.

14.DO NOT locate the compressor air inlet near steam,

paint spray, sandblasting areas or any other source

of contamination. The debris could damage the

motor and pump.

15.Wear safety glasses (meeting ANSI Z87.1 or in

Canada CSA Z94.3-99) and use hearing protection

when operating the unit. Everyday glasses are not

safety glasses.

16.Wear shoes to prevent shock hazards.

17.Tie back long hair.

WARNING

18.Keep fingers away from running compressor. Fast

moving and hot parts may cause injury and/or

burns.

WARNING

19.Be careful when touching the exterior of

compressor, pump, motor and air lines; they may

become hot enough to cause injury.

WARNING

20.Never operate the compressor without a belt guard.

The compressor can start automatically without

warning. Personal injury or property damage could

occur from contact with moving parts.

CAUTION

21.The compressor may be hot even if the unit is

stopped.

WARNING

22.Use of a mask or respirator per chemical

manufacturers’ instructions may be necessary if

there is a chance of inhaling toxic fumes. Read

mask and respirator instructions carefully. Consult

a safety expert if you are not sure about the use of

certain masks or respirators.

BEFORE USING THE AIR COMPRESSOR

Air compressors are utilized in a variety of air

system applications. Because air compressors and

other components (hoses, connectors, air tools,

spray guns, etc.) make up a high pressure pumping

system, the following safety precautions should be

observed at all times.

INSPECT YOUR COMPRESSOR

1. To reduce the risk of injury from accidental starting,

turn switch off and disconnect the power before

checking it.

2. If any part is missing, bent or broken in any way, or

any electrical part does not work properly, keep the

compressor off and disconnected.

3. Check hoses for weak or worn condition before

each use, making certain all connections are

secure. DO NOT use if defect is found.

WARNING

DO NOT operate compressor if damaged during

shipping, handling or use. Damage may result in

bursting and cause injury or property damage.

WARNING

This compressor is not designed for and should not be

used in breathing air applications.

WHEN INSTALLING OR MOVING THE COMPRESSOR

This compressor is extremely top heavy. The

compressor must be bolted to the floor with vibration

pads before operating to prevent equipment damage,

injury or death. DO NOT tighten bolts completely as

this may cause stress to the tank welds.