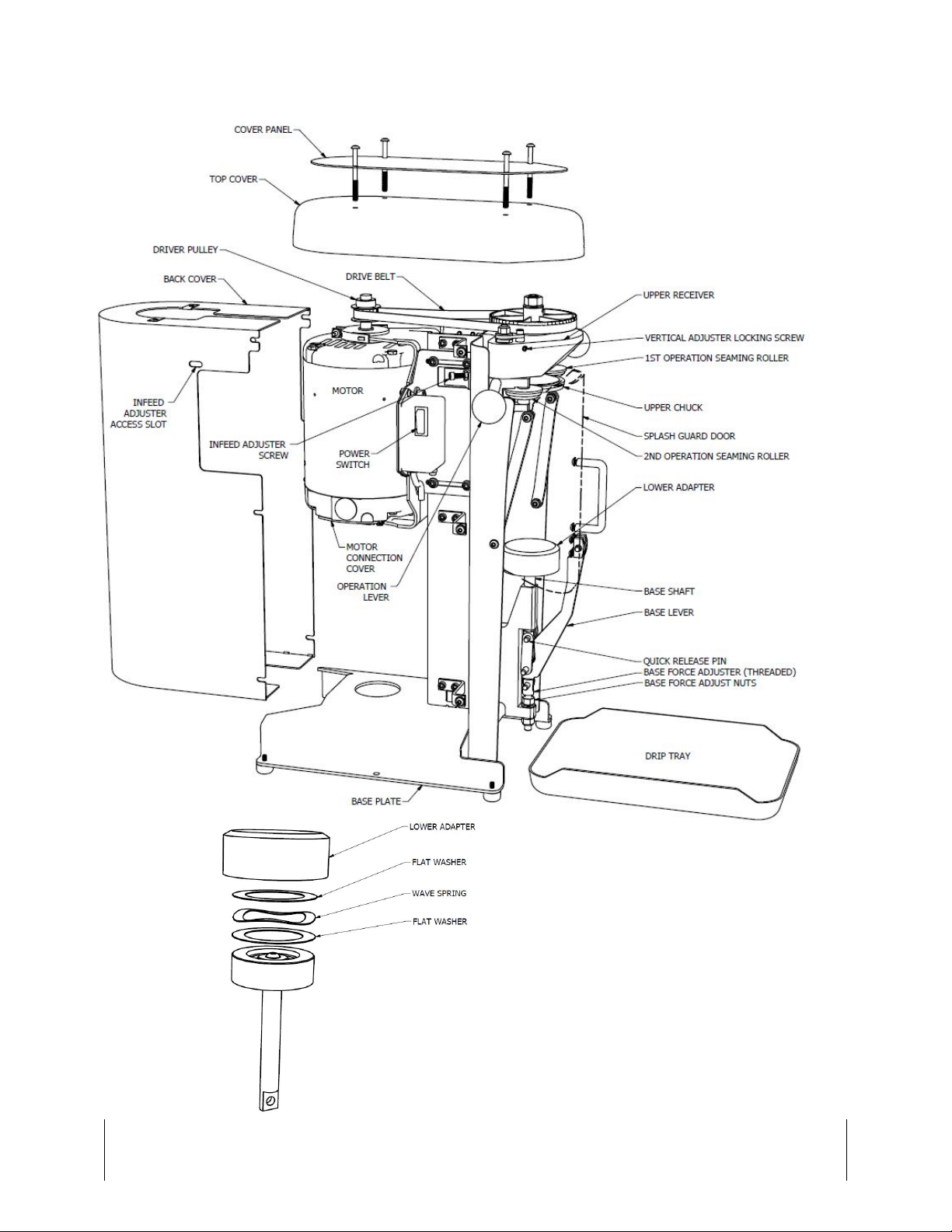

CAPABILITIES

The MODEL 7 Oktober Can Seamer is designed to seam aluminum beverage cans.

Aluminum beverage cans come in many different sizes, and the model 7 can be

configured to seal many of them. Cans with the same “end” size (can top) can

generally be sealed using the same “tooling” set (upper chuck, seaming rollers,

base assembly). Tooling sets are available for end sizes 200, 202, 206, 209, and

300. Each seamer includes one tooling set. Changing tooling sets requires re-

calibration. Each set comes with one or two standard lower adapters. Other

lower adapters are also available, including custom adapters.

Tooling Sets:

A: Size 200 ends. Comes with lower adapter for 250ml cans.

B: Size 202 ends. Comes with lower adapters for 12oz and 16oz cans.

C: Size 202 ends. Comes with lower adapters for 330ml and 500ml cans.

D: Size 202 ends. Comes with lower adapters for 19.2oz and 16oz cans.

E: Size 206 ends. Comes with lower adapters for 24oz cans.

F: Size 209 ends. Comes with lower adapters for 1000ml cans.

G: Size 300 ends. Comes with lower adapters for 32oz cans.

GETTING STARTED

Your seamer comes calibrated and ready to go so you shouldn’t need to adjust

anything. If you do have an issue, check the troubleshooting list at the end of the

manual. There are a few things that may need to be adjusted due to shipping

issues, etc.

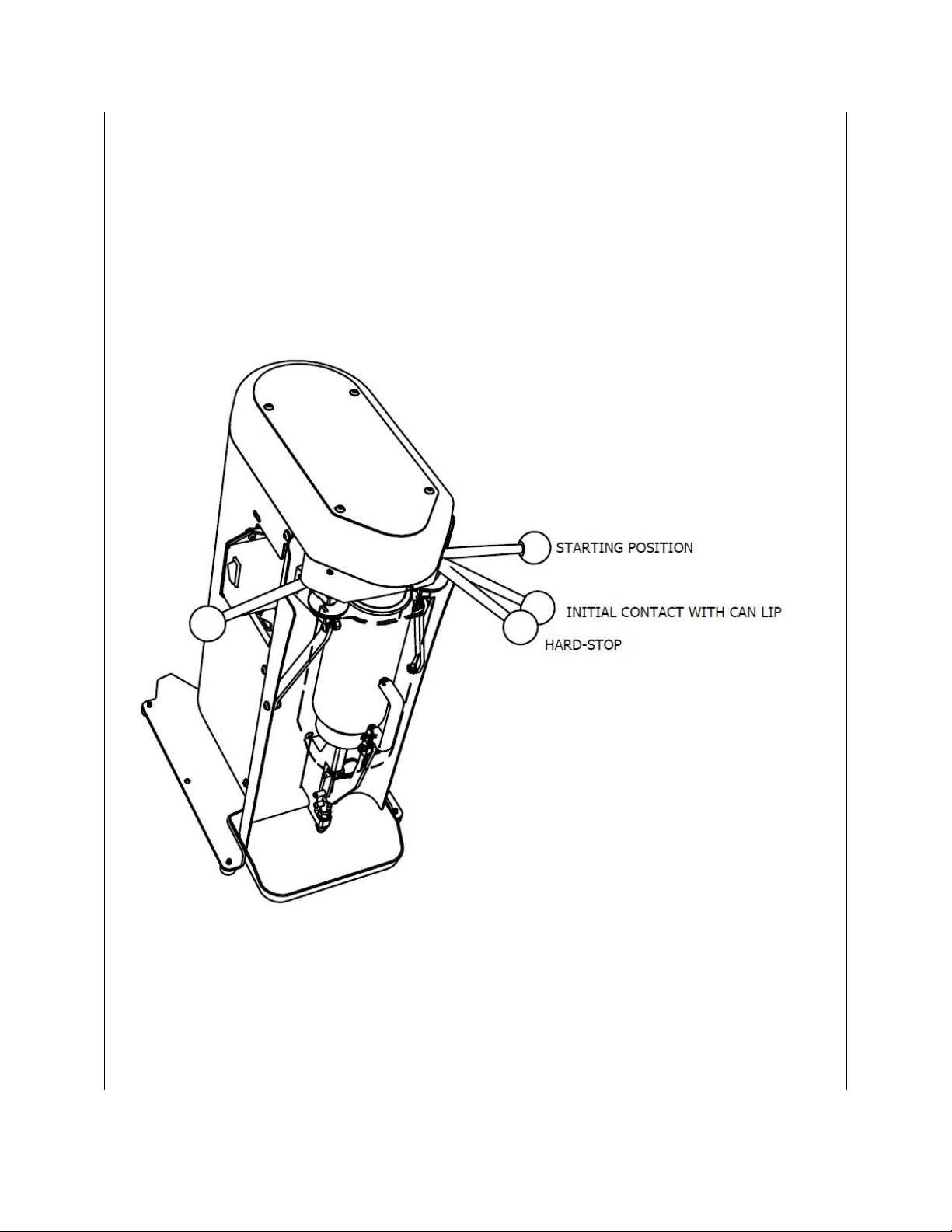

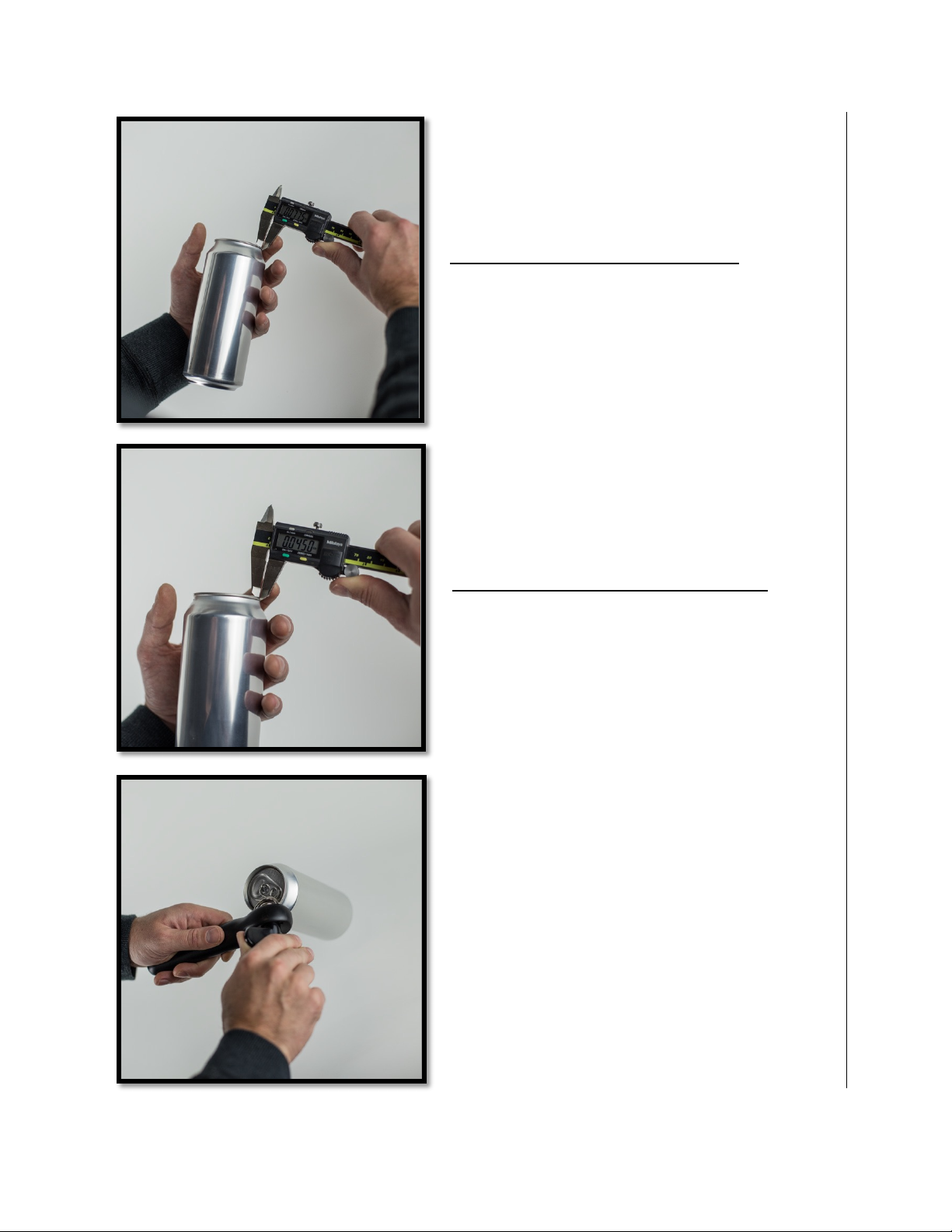

Seaming (check out the how-to videos on our website!)

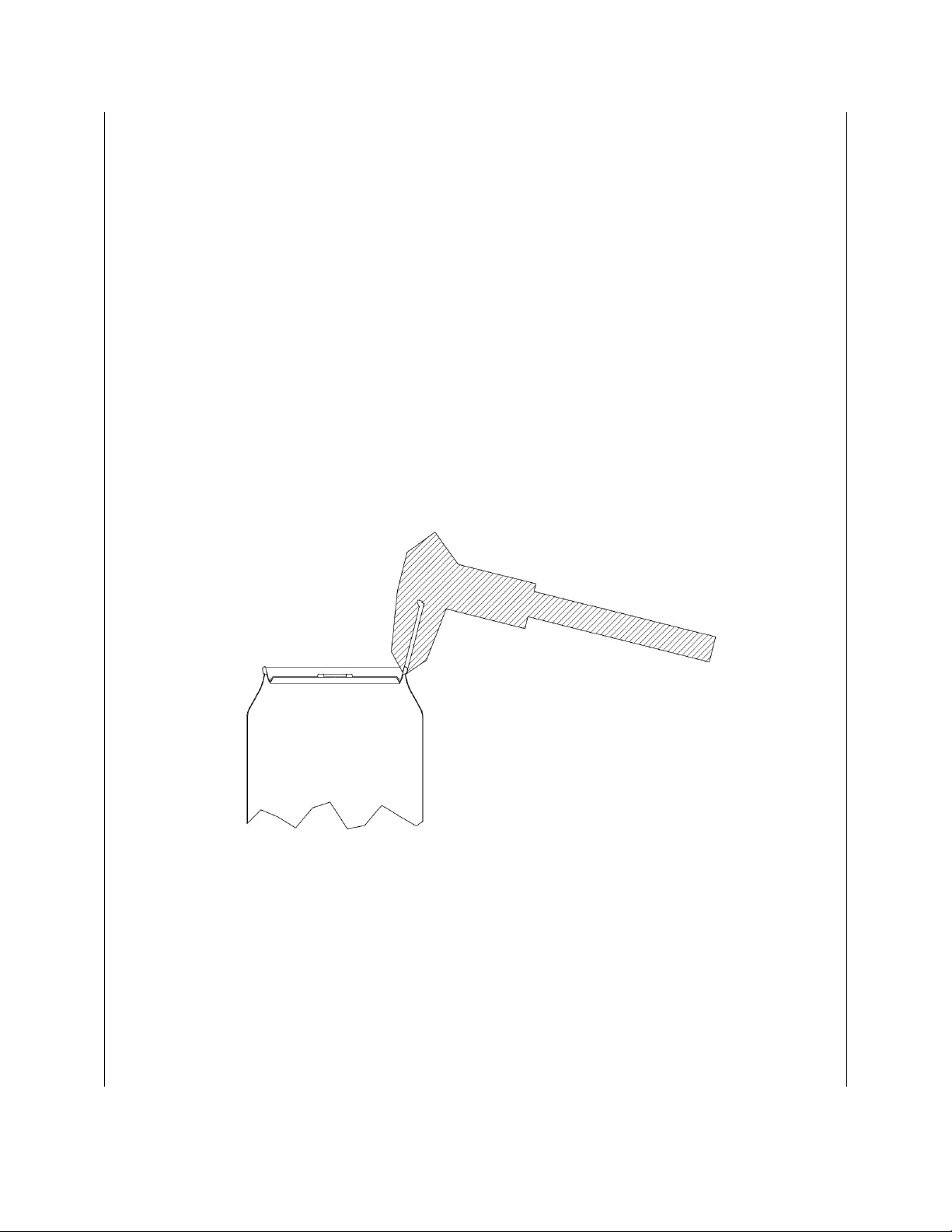

Seaming is super simple. The basic idea is to rotate the right handle until it

contacts a hard-stop, back it off to its starting position, then do the same for the

left handle. The can spins fast enough that the speed the operation levers rotate

can vary, but you also don’t want to slam the handles. Keep in mind that it

doesn’t take much force to seam a can. As soon as the lever has hit its hard-stop

the operation is completed. Make sure to read through the detailed instructions