i

TABLE OF

CONTENTS

TABLE OF CONTENTS

Section Page

1 INTRODUCTION

General Description........................................................................................................................ 1-2

Required Working Space................................................................................................................ 1-2

Machine Specifications................................................................................................................... 1-3

Component Serial Numbers ........................................................................................................... 1-4

2 SAFETY

Machine Misuse.............................................................................................................................. 2-2

Recognize Safety Information......................................................................................................... 2-2

Understand Signal Words............................................................................................................... 2-4

Safety Precautions.......................................................................................................................... 2-4

Battery Safety ................................................................................................................................. 2-8

3 PARTS

Introduction..................................................................................................................................... 3-2

Electric Utility Vehicle (EUV)........................................................................................................... 3-5

Electrical Group .............................................................................................................................. 3-7

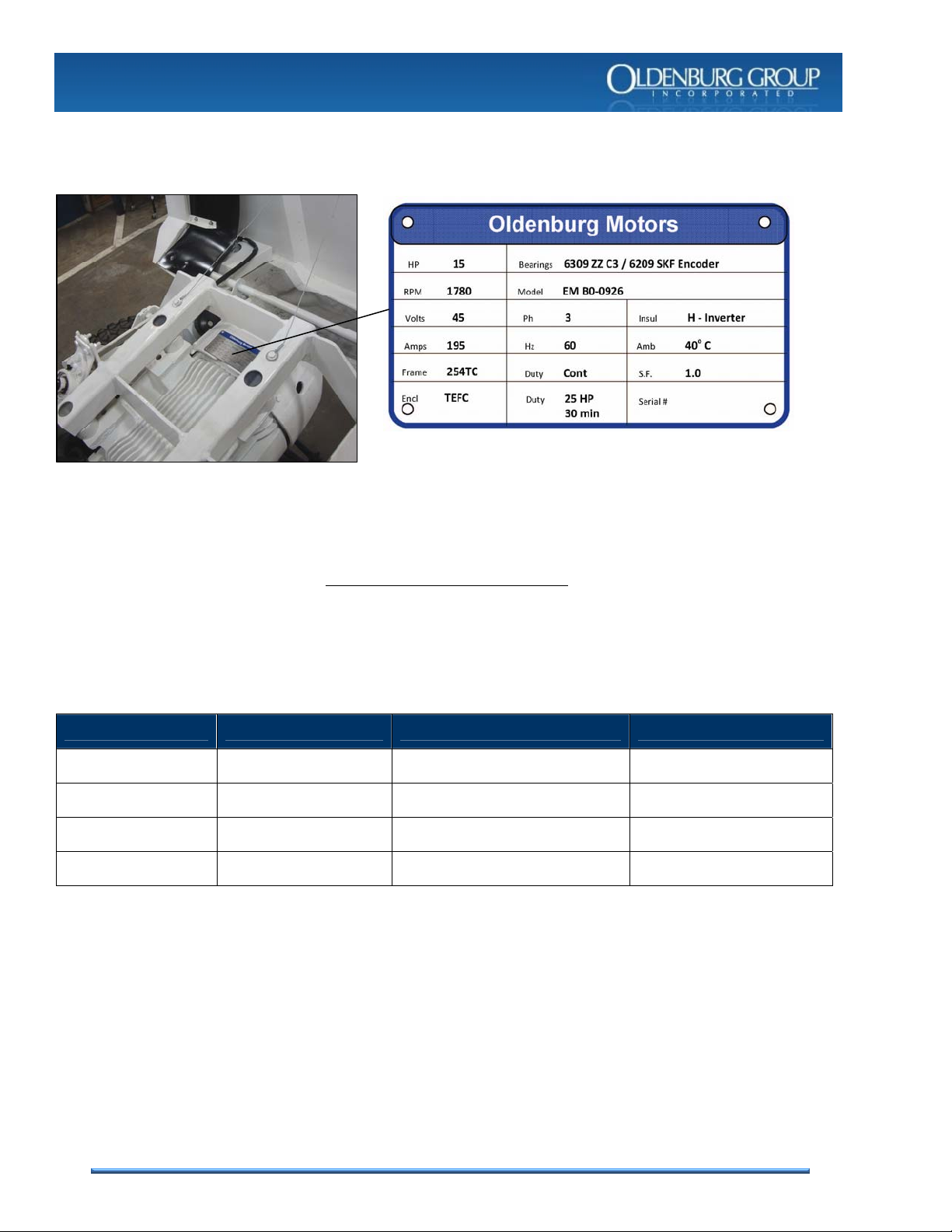

Motor Group.................................................................................................................................... 3-12

Battery Group.................................................................................................................................. 3-13

Wheel Group................................................................................................................................... 3-14

Drop Box Group.............................................................................................................................. 3-15

Axle & Suspension Group............................................................................................................... 3-16

Steering Group................................................................................................................................ 3-19

Driveline Group............................................................................................................................... 3-20

Brake Group.................................................................................................................................... 3-21

Options............................................................................................................................................ 3-23

4 SERVICE

Cleaning.......................................................................................................................................... 4-2

Storage ........................................................................................................................................... 4-2

General Service.............................................................................................................................. 4-3

Service Intervals ............................................................................................................................. 4-7

Service Lubrication ......................................................................................................................... 4-8

Recommended Fluids..................................................................................................................... 4-10

Torque Table................................................................................................................................... 4-10

Electrical Schematic........................................................................................................................ 4-11

Electrical Wiring Diagram................................................................................................................ 4-12