DETAIL K2 MMT4X6O User manual

MMT4X6O man v.191129

DETAIL K2 INC.

1080 Clay Ave., Unit #2

Burlington Ont. L7L 0A1

1-888-277-6960

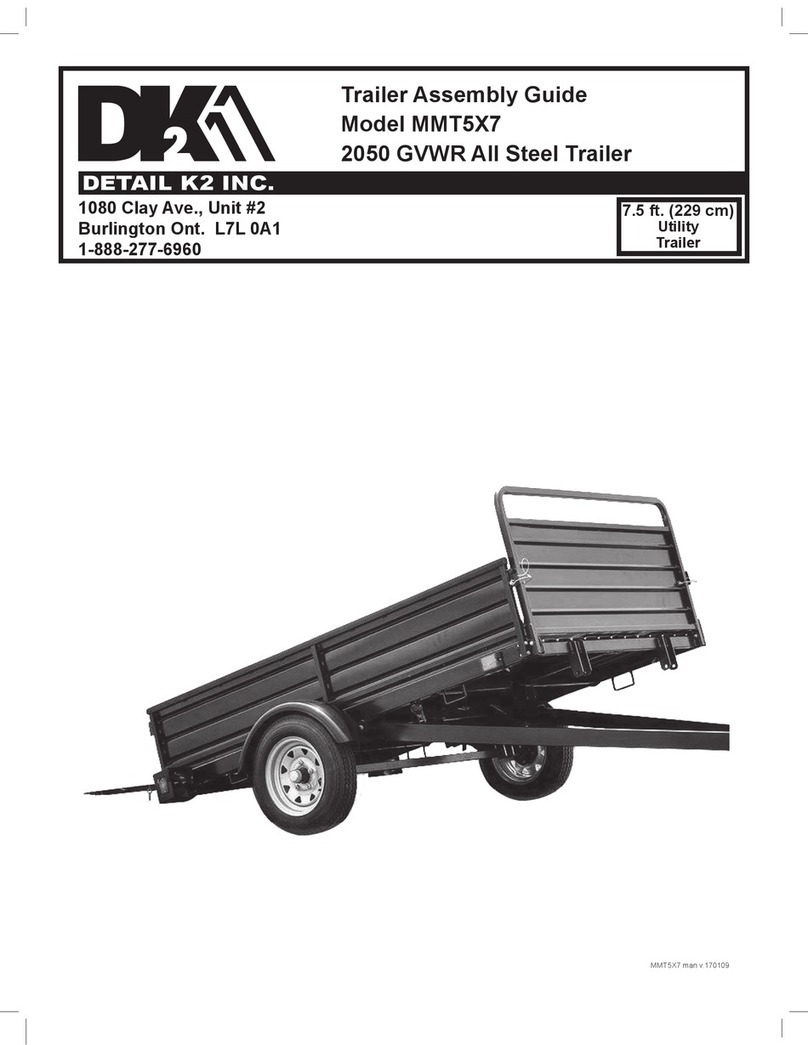

Trailer Assembly Guide

Model MMT4X6O

1600 GVWR All Steel Trailer

6 ft. (182 cm)

Utility

Trailer

En.a2 MMT4X6O man

ENGLISH

STEP 1

Open and unpack all items. Leave lots of working space as you will need to ip the

trailer over later in the assembly.

The trailer frame is shipped upside down as shown. Leave the frame on the cardboard

and use it as your work surface.

v.191129 En.a3

ENGLISH

STEP 2

Place springs as shown, with the spring eye oriented towards the front of the trailer.

Place the 2 pc. L brackets between front cross member and the rst cross member and

use the M12 x 25 mm bolts to fasten L brackets onto the frame.

L Bracket

Front

Positioning Pin

Back

En.a4 MMT4X6O man

ENGLISH

STEP 3

Insert the two M14 x 95 mm bolts from inside through the springs, nuts, washers and

fender L-brackets, then tighten just until spring is secure. Do not over-tighten, since the

brackets will need adjustment to the fenders later and it may collapse spring channel.

Place the tongue tube between the two drawbar reinforcment brackets by using M14 x

85 mm bolts.

Install the coupler and safety chains using the M10 x 80 mm bolts and M10 lock nuts

provided.

The front bolt passes though the end link of the safety chain as it is inserted through

the tongue tubes. Tighten both bolts.

v.191129 En.a5

ENGLISH

STEP 4

Place the Axle on the top pf the Spring. Align depression on Axle with protrusions on

Spring.

On each end of the Axle, place Spring Plates under Spring and insert M12 x 90 U-bolt

downward over the Axle and through the mounting hole in the Spring Plate. Adjust the

Spring Plates slightly to allow the holes to line up.

Secure the Axle with M12 washers and M12 Nylock nuts.

NOTE: Insert the raised point on the spring into the concave on the axle.

Make sure that the axle is in the right position.

En.a6 MMT4X6O man

ENGLISH

STEP 5

Install the tires. Snug all ten wheel nuts provided.

The wheel nuts will need to be torqued after the trailer is ipped over and the

wheel can be better held.

NOTE: Tapered ends of wheel nuts face inward toward wheel.

v.191129 En.a7

ENGLISH

STEP 6

Pre-Wiring

The wire harness are pre-assembled under the frame. The pre-assembled wiring

harness is pre-mounted on the trailer and must be connected to the harness that goes

to the front of the trailer tongue.

NOTE: Make sure all connections are accessible for light mounting when

trailer is ipped over.

Mount the light assemblies onto the side of the rear portion of the frame using the M6

square neck bolts, M6 washers and M6 nylock nuts. Plug the light connector into the

wire harness. Mount the side marker onto the side of the front portion of the frame

using the self-tapping screws. Plug the light connector into the wire harness.

Marker Light Quick-Connect Tail Light Quick-Connect

Marker Light Quick-Connect

Q

u

i

c

k

-

C

o

n

n

e

c

t

En.a8 MMT4X6O man

ENGLISH

STEP 7

Flip the trailer over and install the fenders

CAUTION! Rolling the trailer over will require assistance. The trailer at

this point weighs an estimated 300 lb. (136.3 kg).

The fenders now need to be assembled. Secure each fender by fastening the nuts and

bolts provided with the fender to the fender brackets on the frame. Tighten the 8 nuts

securely.

Shown from below in drawing with axle and wheels removed for clarity.

v.191129 En.a9

ENGLISH

STEP 8

Install lights.

Install the lights and complete the wiring.

Mount the side marker onto the side of the front portion of the frame using the self-

tapping screws. Plug the light connector into the wire harness..

NOTE: Use Dielectric grease on each connector for corrosion prevention

En.a10 MMT4X6O man

ENGLISH

STEP 8 (CONTINUED)

Attach rear light brackets and install light assemblies. Connect light assembly to wiring

harness

The driver’s-side tail light is the one with the clear lenses on the bottom, the licence

plate bracket needs to be installed on the driver’s side as well at the same time.

Attach all necessary wiring and fasten lights to side of trailer.

NOTE: Use Dielectric grease on each connector for corrosion prevention

v.191129 En.a11

ENGLISH

STEP 9

Put Gate pin through Bush and Spring, then tighten with nut.

En.a12 MMT4X6O man

ENGLISH

FINAL STEPS

IMPORTANT

MUST TORQUE WHEEL NUTS TO 80 lb.

Connect to vehicle to conrm all lights are working correctly.

Inspect trailer once more to make sure all steps were completed

properly. Remember to recheck all nuts before use to make sure

they are all properly tightened.

CAUTION: It is the trailer owner’s responsibility to periodically check all

hardware is secure and fastened properly

MMT4X6O man v.191129

DETAIL K2 INC.

1080 Clay Ave., Unit #2

Burlington Ont. L7L 0A1

1-888-277-6960

6 ft.

Utility

Trailer

Read the owner’s manual over carefully before you begin using your trailer.

Owner’s Manual

Model MMT4X6O

1600 GVWR All Steel Trailer

En.m2 MMT4X6O man

ENGLISH

The following pages contain the assembly diagrams and complete parts list

IMPORTANT SAFETY CHECK LIST

Trailers are generally not used everyday. Your trailer may sit for extended periods of time between uses making it very

important to check all components thoroughly before each use. Following these simple instructions will maximize the life of

your trailer and help you safely transport your cargo.

DO NOT ABUSE THE TRAILER. Trailer performance is best if you follow the guidelines set forth in this

manual. Do not force the trailer to do a job it’s not designed for. Know your trailer; learn its applications

and limitations.

1. Make sure the towing vehicle as well as the hitch is capable of towing the trailer. Check your vehicle owner’s manual

for trailering ratings.

2. Inspect the trailer and all of its parts before each use.

3. Check the operation of all lights. Operating lights are mandatory on a trailer.

4. Check to ensure Wheel Bolts are tight. Torque to 80 ft.-lbs. Re-tighten after the rst 50 miles or 80 kilometers.

5. Check the tire pressure. Maximum 80 PSI (552 KPA) when carrying the maximum rated load.

6. Re-pack the wheel bearings every 2000 miles or 3200 kilometers or a minimum of once every year.

7. Check that the trailer coupler is fastened securely onto the trailer ball. The trailer ball must be a 2” ball.

8. Make sure the safety chain is attached to the trailer and the towing vehicle.

9. If your trailer has an optional side kit, make sure all bolts and pins are in place before transporting your trailer.

10.Do not exceed the Gross Vehicle Weight Rating (G.V.W.R.) which is shown on the trailer serial / certication label.

11.Balance and secure the load on the trailer. See “Trailer Loading” section in this manual.

12.Lubrication of the coupler, springs and the tilt mechanism should be done periodically to stop corrosion and keep parts

moving freely.

DANGER

yKEEP CHILDREN AWAY. Be sure children are kept a safe distance from the trailer operating area.

yNEVER SIT OR RIDE ON THE TRAILER. Serious injury or death could occur.

yEXERCISE EXTREME CAUTION WHEN TILTING THE TRAILER. There are many areas of the trailer where injury

can occur if used improperly. The trailer may tilt quickly and unexpectedly during the loading and unloading process.

The tilt option should not be used for heavy loads.

yRamps should be used for loading heavy items.

yDO NOT drive with the trailer in the tilted position.

yDO NOT load more than one all-terrain vehicle on to this trailer.

yIf the trailer is incorrectly attached to the vehicle, it could pull away from the vehicle and fall o.

ySecure trailer to the towing vehicle before transportation. Make sure coupler is locked and the safety chains are

attached to the trailer and the vehicle.

ySecure your cargo into the trailer properly and in compliance to local laws.

yWhen driving do not exceed the speed limit. Braking time can be considerably longer when a vehicle is towing a loaded

trailer.

yAny modications made to the trailer or parts of the trailer will void the trailer warranty and release Detail K2 Inc. of any

responsibility for damages, injuries or accidents incurred.

Replacement Lenses

Rear Red Lens (Large) 41237

Rear Red Lens (Small) 41238

Marker Lens (Orange) 41239

yONLY USE ORIGINAL EQUIPMENT PARTS AND ACCESSORIES. Consult Detail K2 Inc. for the

recommended accessories. The use of improper accessories may cause hazards or injuries.

v.191129 En.m3

ENGLISH

LIGHTING & WIRING MAINTENANCE

WIRING LEGEND

Symbol Color Description Operation

G Green Wire Passenger Side (Right) Right Signal Brake

B Brown Wire Running Lights Tail light marker Yellow Front Side Markers

Y Yellow Wire Driver Side (Left) Left Signal Brake

W White Wire Ground Trailer Ground

yNOTE: Brake light goes out on the side that is signaling.

zLower lament (Brighter light) = Brake & Signal

zHigher Filament (Dimmer Light) = Running Lights

To test vehicle wiring;

You will need a 12v light tester. Attach the wire clamp of the tester to the ground wire on the vehicle plug.

Then touch the tester pin into one of the vehicle plug contacts. Turn on the corresponding vehicle operation i.e. Running

lights. This will illuminate the tester light if the vehicle wiring is correct. Follow this same procedure for the signal and brake

lights.

To test the Trailer wiring;

Once you have conrmed that the vehicle trailer plug is operating properly, connect the trailer plug to your vehicle.

Proceed to test each of the lights and power leads using your 12v light tester. Follow the wiring legend and diagram to test

each corresponding wire for power when trailer light is not operating.

Always be sure to check your brake, running and signal lights before each use. Make sure that all of your connections are

solid and that all wiring is in good condition.

Note: Bare, stripped or pinched wire will cause a short in the trailer, which will cause the vehicle fuse to blow. A

solid ground is required for your lights to work properly. All contacts must be to bare metal. Light covers should

be well maintained and kept clean. Be sure that your lights are always visible, not obstructed by your load.

LOADING YOUR TRAILER

A/B.Distribute the weight evenly.

C. Center the load over the axle, keeping about 10% of the weight on the tongue. (If vehicle wheels are not on a

crossbeam you will need to add wood to the oor to support each axle).

D. Center the load from side to side.

E. Always secure your cargo into the trailer properly and in compliance to local laws.

CAUTION

Do not build your trailer load higher than 3’. Higher loading will aect trailer handling due to increased wind resistance.

This may cause violent movements, accidents and serious injury.

TRAILER CAPACITY:

zNever overload your trailer. Each trailer has a maximum payload that should not be exceeded. Overloading your trailer

could cause serious damage to your trailer as well as the towing vehicle. Please refer to your trailer serial / certication

label located on the frame of the trailer for capacity details.

zThe Gross Vehicle Weight Rating (G.V.W.R.) is:

The Weight of the Trailer + The Maximum payload the trailer can carry. The trailer weight and the payload must not

exceed this (G.V.W.R.) weight rating.

zBe sure that any load carried in your trailer does not extend beyond the frame of your trailer. Never place loads on one

side only.

Tongue Weight

zThe tongue weight is 10% of the load (this does not include the weight of the trailer).

zThe load is divided so that 90% of the load is over the axle and 10% is over the tongue.

En.m4 MMT4X6O man

ENGLISH

TRAILER COUPLER

A = Locked B = Unlocked

To adjust coupler to ball;

Set coupler and tongue on to the 2” trailer ball on your vehicle.

Raise the locking lever, push up on channel lock and turn nut to tighten or loosen the coupler.

Proper adjustment is obtained when coupler is as tight as possible on the ball and locking lever can still be opened and

closed.

Before towing your trailer be sure to check the capacity of your trailer hitch on your vehicle (never exceed this or

your trailers capacity). The Detail K2 Trailer is equipped with a 2” coupler and must be used with a 2” trailer ball. Make

sure that the trailer ball is completely engaged in the coupler ball

WHEEL BEARING & HUB ASSEMBLY

NOTE: Bearings should be re-packed every 2000 miles or 3200 kilometers.

NO PARTS ARE MORE CRITICAL FOR THE DEPENDABLE PERFORMANCE OF YOUR TRAILER

THAN THE BEARINGS, RACES, AND SEALS. TO ENSURE THAT YOUR TRAILER PERFORMS

RELIABLY, YOU SHOULD INSPECT THE BEARINGS, RACES, AND SEALS AND REPACK THE

BEARINGS EVERY 12 MONTHS OR 2000 mi. (3200 km). THIS IS EASILY FOUND ON THE

INTERNET BY SEARCHING “TRAILER WHEEL BEARINGS MAINTENANCE”

A

B

Item # Description Qty.

11” Axle Bearing Kit 1

1A Bearing Cup (press t) 2

1B 1” Bearing Cone 2

1C Grease Seal 1

1D 2” Axle Dust Cap 1

Item # Description Qty.

1E 1” Axle Castle Nut 1

1F 3/16” Cotter Pin 1

2Hub (bare) with bearing race 1

3Axle c/w hubs and bearings 1

Part # _____ Axle Bearing Kit includes all parts 1A to 1E.

Note: Part 1A Bearing Race is press-t into the Hub and may not need to be replaced when changing bearings.

v.191129 En.m5

ENGLISH

Re-packing Wheel Bearings

1. Loosen wheel bolts (Do not remove!).

2. Support trailer so the wheel is o the ground. (jack stack – oor jack – block)

3. Remove nuts and wheel.

4. Disassemble hub

5. Clean hub and pack bearings with wheel bearing grease.

6. Re-install bearings, nut and cotter pin.

CAUTION: DO NOT over tighten nut. The hub must turn freely and without play.

7. Re-attach bolts and wheel. (Torque to 80 lbs.)

TRAILER LICENSING

The Detail K2 kit trailer MUST BE CERTIFIED after assembly by a local garage which is approved and holds a license to

provide safety certicates for roadway vehicles.

In order to register your trailer with the Department of Motor Vehicles or Ministry of Transportation and obtain a license

plate you will need to have either the NVIS form in Canada or the Manufacturers Certicate of Origin in the US lled

out and signed by the dealer transferring ownership to you. This form is found in your trailer manual package. Take this

form along with the bill of sale (cash register receipt) and safety certicate to your local Department of Motor Vehicles or

Ministry of Transportation licensing oce. Once you pay the appropriate fees you will be issued a title or registration and

license plate to be attached to the trailer.

US Residents

To Contact National Highway Trac Safety Administration

If you believe that your vehicle has a defect, which could cause an accident, personal injury or death, immediately inform

the National Highway Trac Safety Administration (NHTSA) in addition to notifying Detail K2

If NHTSA receives similar complaints, or nds safety defects existing in a group of vehicles it may open an investigation or

order a recall and remedy campaign. However, NHTSA cannot become involved in individual problems between you, your

dealer, or Detail K2.

To contact NHTSA, you may either call the Auto Safety Hotline toll-free at 1-800-424-9393 (or 366-0123 in Washington,

DC area) or write to: NHTSA, U.S. Department of Transportation, Washington, DC 20590.

En.m6 MMT4X6O man

ENGLISH

PARTS LIST

Part No. Description Qty.

MMT4X6O-1 Drawbar 1

MMT4X6O-2 Body 1

MMT4X6O-3 Back gate 1

MMT4X6O-4 Axle 1

MMT4X6O-5 Wheel 2

MMT4X6O-6 3-leaf spring 2

MMT4X6O-7 Fender 2

MMT4X6O-8 Fender L bracket front & rear 4

MMT4X6O-9 Drawbar reinforcment bracket 2

MMT4X6O-10 Left light housing 1

MMT4X6O-11 Right light housing 1

MMT4X6O-12 Tail light with harness 2

MMT4X6O-13 License holder 1

MMT4X6O-14 Coupler 1

MMT4X6O-15 Safety chain 1

MMT4X6O-16 Side marker 2

MMT4X6O-17 Side marker bolts 4

MMT4X6O-18 Side market nuts 4

MMT4X6O-19 M8 x 20 hex bolt 8

MMT4X6O-20 M8 x 45 hex bolt 2

MMT4X6O-21 M10 x 25 hex bolt 8

MMT4X6O-22 M12 x 25 hex bolt 4

MMT4X6O-23 M12 x 80 hex bolt 2

MMT4X6O-24 M14 x 85 hex bolt 4

MMT4X6O-25 M14 x 95 hex bolt 2

MMT4X6O-26 M8 lock nut 10

MMT4X6O-27 M10 lock nut 16

MMT4X6O-28 M12 lock nut 6

MMT4X6O-29 M14 lock nut 6

MMT4X6O-30 M14 nut 2

MMT4X6O-31 φ8 at washer 10

MMT4X6O-32 φ10 at washer 16

MMT4X6O-33 φ12 at washer 6

MMT4X6O-34 φ14 at washer 8

MMT4X6O-35 Wheel nut 10

MMT4X6O-36 Axle sh plate 2

MMT4X6O-37 M10 U-bolt 4

MMT4X6O-38 Lock pin 2

MMT4X6O-39 Hinge bracket 2

MMT4X6O-40 D lock 2

v.191129 En.m7

ENGLISH

SCHEMATIC DRAWING

1

2

3

4

5

6

7

9

10

11

12

13

14

15

16

17

18

8

19 21

22

23

24

20

26 27

28

31

32

33

35

36

37

38

39

40

25

29

30

34

MMT4X6 guide d’assemblage v.191129

DETAIL K2 INC.

1080 Clay Ave., Unit #2

Burlington Ont. L7L 0A1

1-888-277-6960

Guide d’assemblage de la remorque

Modèle MMT4X6O

Remorque 1600 GVWR tout acier

6 pi (182 cm)

Remorque

Utilitaire

Table of contents

Languages:

Other DETAIL K2 Utility Vehicle manuals

DETAIL K2

DETAIL K2 MMT5X7G-DUG User manual

DETAIL K2

DETAIL K2 MMT6X10 User manual

DETAIL K2

DETAIL K2 MFT4X8 User manual

DETAIL K2

DETAIL K2 MMT-ATV Use and care manual

DETAIL K2

DETAIL K2 MMT4X60 User manual

DETAIL K2

DETAIL K2 MMT4X6 User manual

DETAIL K2

DETAIL K2 MMT5X7G User manual

DETAIL K2

DETAIL K2 MMT5X7 User manual

DETAIL K2

DETAIL K2 MMT5X7G User manual

DETAIL K2

DETAIL K2 MFT4X8G User manual