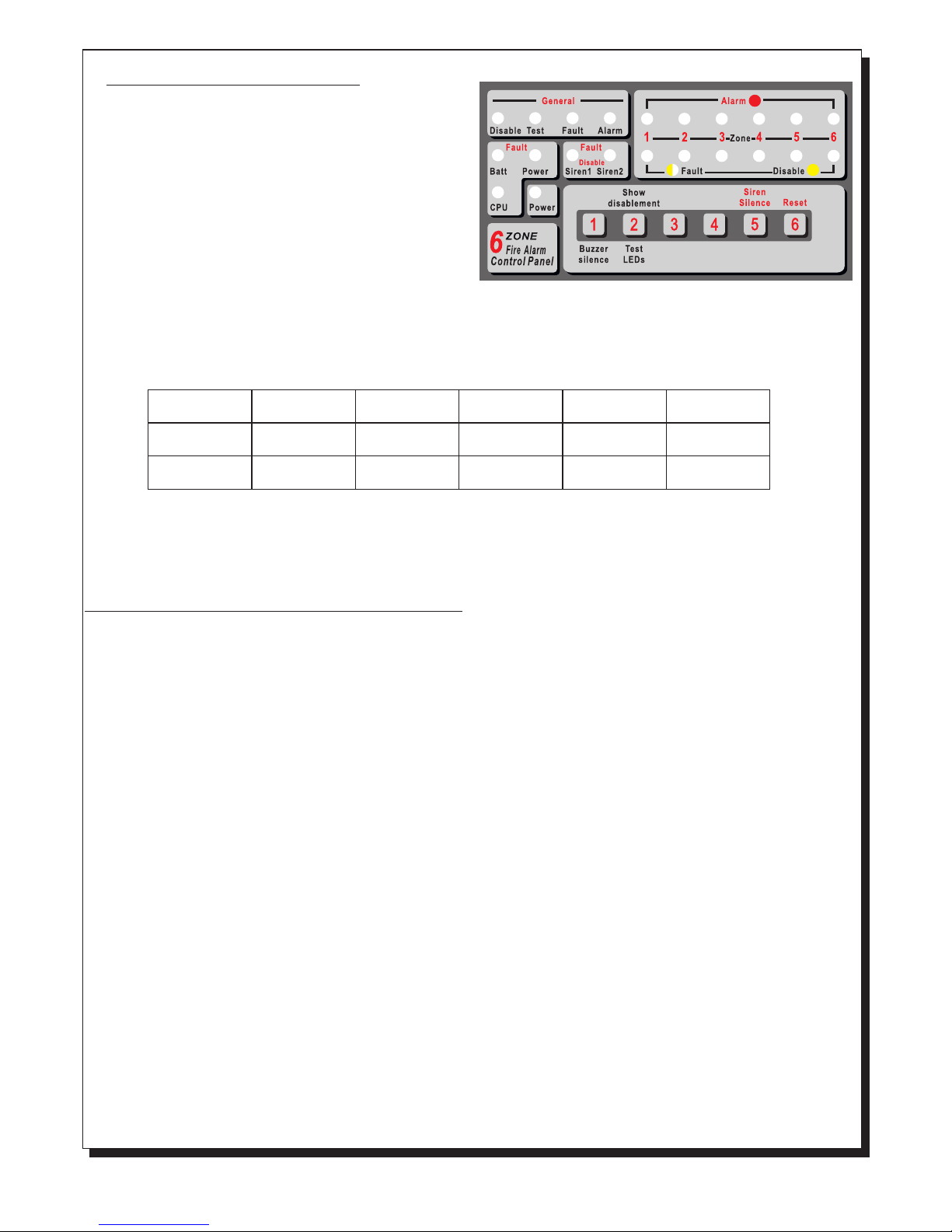

Indication LED description

The schematic shows the control keyboard and the

indication plate of a 6 zone BS-636 panel. Starting from the

top left side we can see 4 indicators marked 'General'.

The 'Disable' LED lights in every DISABLE condition.

The 'Test' LED lights in every TEST condition .The panel

does not has test condition as specified in 11 of EN 54-2.

The 'Fault' LED lights in every FAULT condition. Blinks

when we have a FAULT and the buzzer is silenced.

The 'Alarm' LED lights when we have an ALARM condition.

Blinks when we have an ALARM and the buzzer is silenced.

The next group of indicators is the 'Alarm' indication LEDs.

These indicators light when a corresponding zone issues an ALARM condition. Below this group we have the

'Fault/Disable' indication for each zone. When the panel monitors an open or short circuit conditions in a zone then the

corresponding LED will blink. If a zone is disabled the corresponding LED will light.

Below the `General` indicator group we can find the indication group called `Fault`. The 'Batt' LED and 'Power' LED in

combination, show us faults concerning the power supply. These combination are shown in the panel below.

Batt Fault

Power Fault

Lack of

AC voltage

Battery

Overcharging

Battery

Discharged

Battery

Absent

Charger

Error

Lights

----

Lights

Lights

Lights

Blinks

Blinks

Lights

Blinks

Blinks

The 'CPU' LED lights to indicate a problem with the main processor unit (System fault).

The green 'Power' LED lights to indicate valid internal voltages and blinks when the mains AC power supply fails.

.

The LEDs marked 'Siren1' and 'Siren2' correspond to the siren outputs. If a siren out has a short circuit or open circuit then

the corresponding LED will blink. If a siren is disabled the corresponding LED will light.

Control keyboard description/operation

The panel is controlled/ operated using the six numeric keys (1 to 6) found on the front panel. When a key is pressed a short

tone is issued.

The panel has three access levels.

Access level 1:

has all the functions that can be done directly from the user without using a code. These operations are:

Buzzer silence / Buzzer reactivation . If an alarm of fault condition is issued then the internal buzzer will sound. Pressing

the "1" key will silence the buzzer. ( The buzzer sounds periodically once every minute.) Pressing this key again will reactive

the buzzer.

Viewing disabled sirens-zones/Lamp test. Pressing the "2" key will have the following affect. If any sirens are disabled

then the panel will issue 3 short tones, by lighting the ‘General Disable’ LED, and the disabled sirens will be shown by

lighting the corresponding LEDs Siren1 and Siren2 of the disabled sirens. Then the LEDs will stop lighting and the panel

will issue again 3 short tone, by lighting the ‘Zone Disable’ LED, and the disable zones will be shown by lighting the

corresponding LEDs of the disabled zones. After a while these indicators are switched off and a lamp test is conducted by

lighting the LEDs. The panel then returns to normal operation. The above tests can be conducted only if the panel is in

quiescent state (No fault or alarm conditions).

Access level 2:

Includes all the functions that the user can do and an access code is required. The code is "34”, it is the same for all panels

and cannot be changed. The functions that can be implemented using this code are the following:

Siren Silence. When an alarm is issued and we want to silence the sirens then we must enter the user code

( 34 ) and then the keys number '5' and '5'. The sirens are silenced but the internal buzzer continues to sound. The panel

remains in normal operation. A new alarm from another zone will resound the sirens.

Panel Reset. When an alarm or fault condition has occurred and we want to reset the panel we must enter the user code

(34) and then the keys number '5' and '6’. The panel lights all LEDs in sequence and then enters normal operation.

Zone enable/disable. If we want to disable the operation of specific zones then we must enter the user code

( 34 ) and then the keys number '5' and '4'. The LED marked 'General disable' start to blink, and if a zone is disabled the

Page 2 from 9 921636000_09_023