[4]

General Information

Introduction

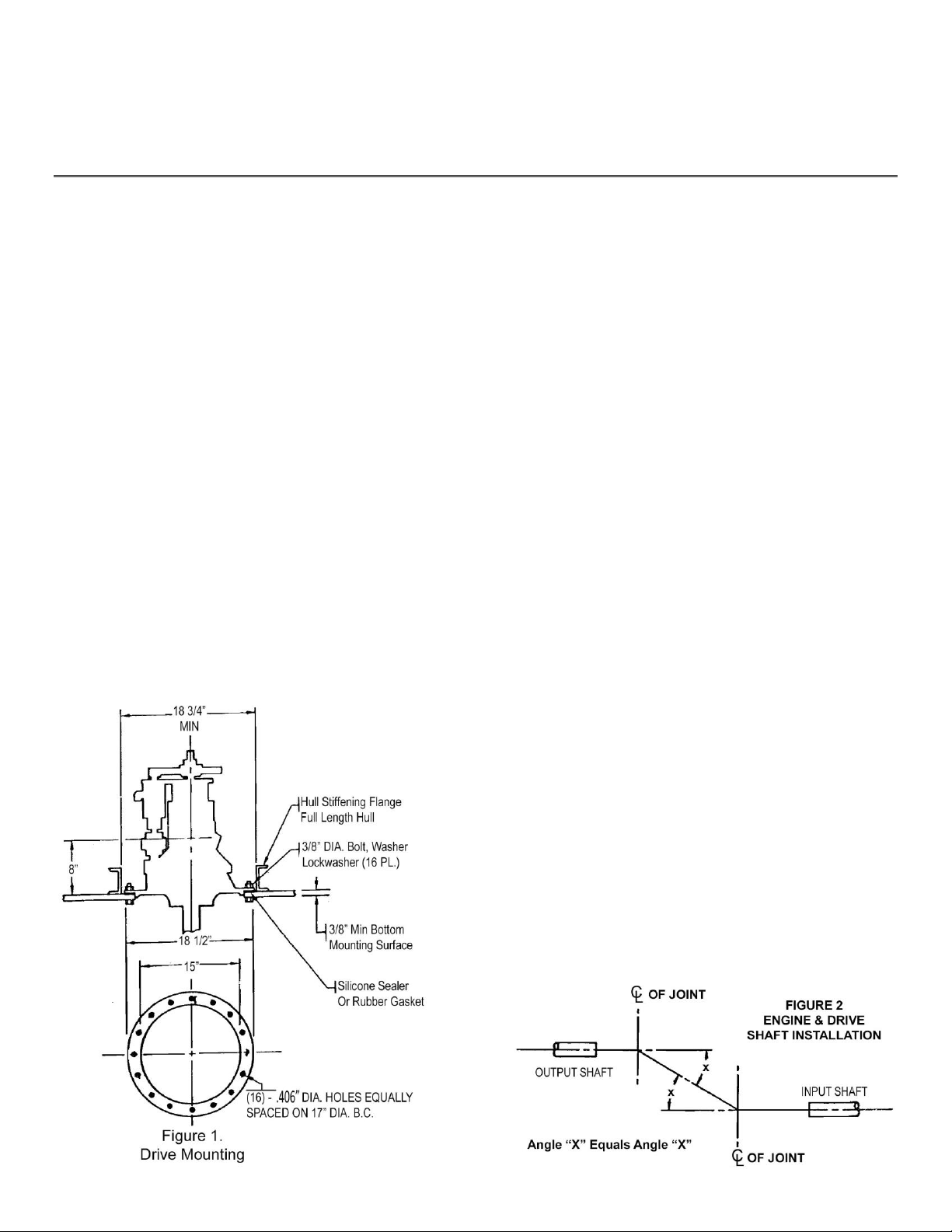

This manual will give you information regarding the

installation, operation, and maintenance of the

U360 Steerable Strut Drive.

The efficiency of a unit and the length of service it

gives are in the hands of the operator of this

equipment. Inspection and preventative

maintenance measures carried out on a regular

schedule will insure long and trouble-free operation.

It is, therefore, to the operator’s advantage to study

and to follow the outlined installation and

maintenance instructions.

For warranty protection, your drive must be

installed to the specification outlined in this manual

and be equipped with a 7-500-235 coupling

assembly and shear pin. Shear pins must meet

Hydro Drive Specifications (Part No. 1030-11).

Description

The U360 Strut Drive is a propulsion system which

is equipped with a propeller strut which can be

rotated continuously through a full 360° so that full

thrust can be directed in any direction.

The drive consists of six functional assemblies: the

upper housing assembly, center housing assembly,

vertical housing assembly, lower housing

assembly, hydraulic system assembly, and power

steering assembly.

The drive is rated for 100 horsepower at 2400 RPM

continuous operation and for 130 horsepower at

2800 RPM intermittent operation. The output shaft

of the engine must rotate counter-clockwise when

looking at the end of the shaft. Drive weight is 370

pounds, including oil.

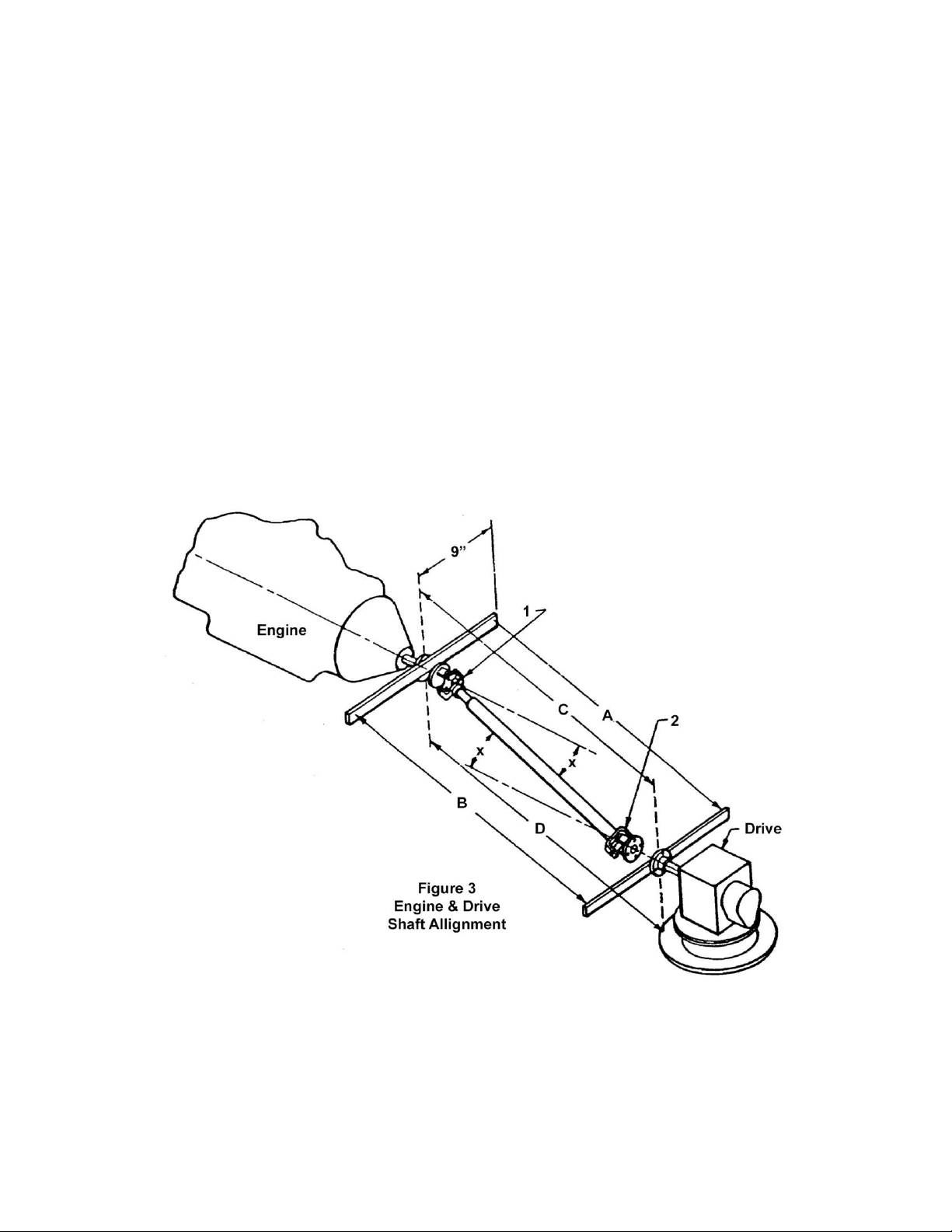

Power is transmitted from the engine to the drive

through a two-joint assembly incorporating a slip

joint together with a tubular connecting shaft. The

drive input flange must be equipped with a torsional

vibration damper. For trouble-free operation, the

drive and engine must be carefully aligned.

The propeller is driven through two sets of spiral

bevel gears. One set of gears is locked in the upper

housing and the second in the lower housing. The

total reduction ratio is 2:1.

The hydraulic system is comprised of a high-

pressure oil pump, oil filter, oil cooler, reservoir tank

and steering motor. The hydraulic system includes

the lubrication system and power steering system.

The high-pressure pump delivers constant power to

the steering motor at all times. The pump also

circulates the lubrication oil throughout the drive.

Steering ratio is 1:1 (360° rotation of the steering

wheel gives 360° rotation of the lower unit).

Normal operating pressure range of this system is

between 2 and 10 PSI, a higher pressure will

indicate a clogged oil filter only.