TABLE OF CONTENTS

MODELS 868 AND 869 DIGITAL THERMOMETERS

SECTION PAGE

SECTION 1 INTRODUCTION ....................................................1

1.1 General Description....................................................................................................................1

1.2 Features ................................................................................................................................................1

SECTION 2 INSTALLATION......................................................1

2.1 Unpacking ..........................................................................................................................................1

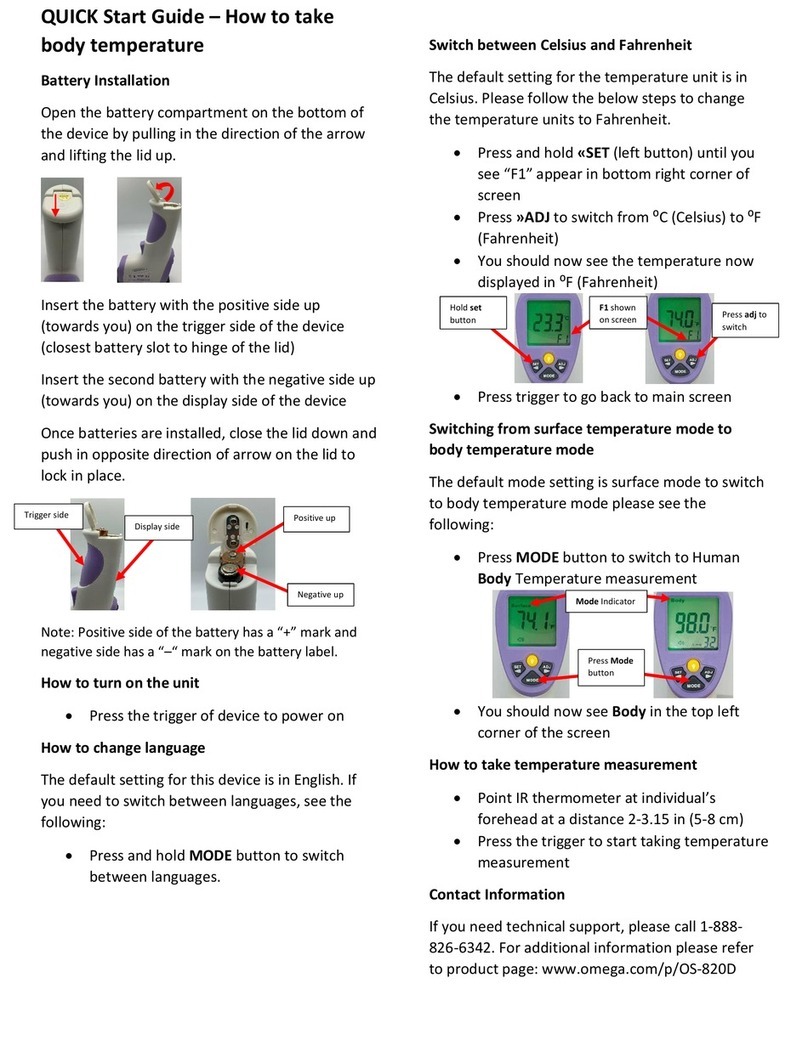

2.2 Battery Installation......................................................................................................................2

SECTION 3 OPERATION ........................................................2

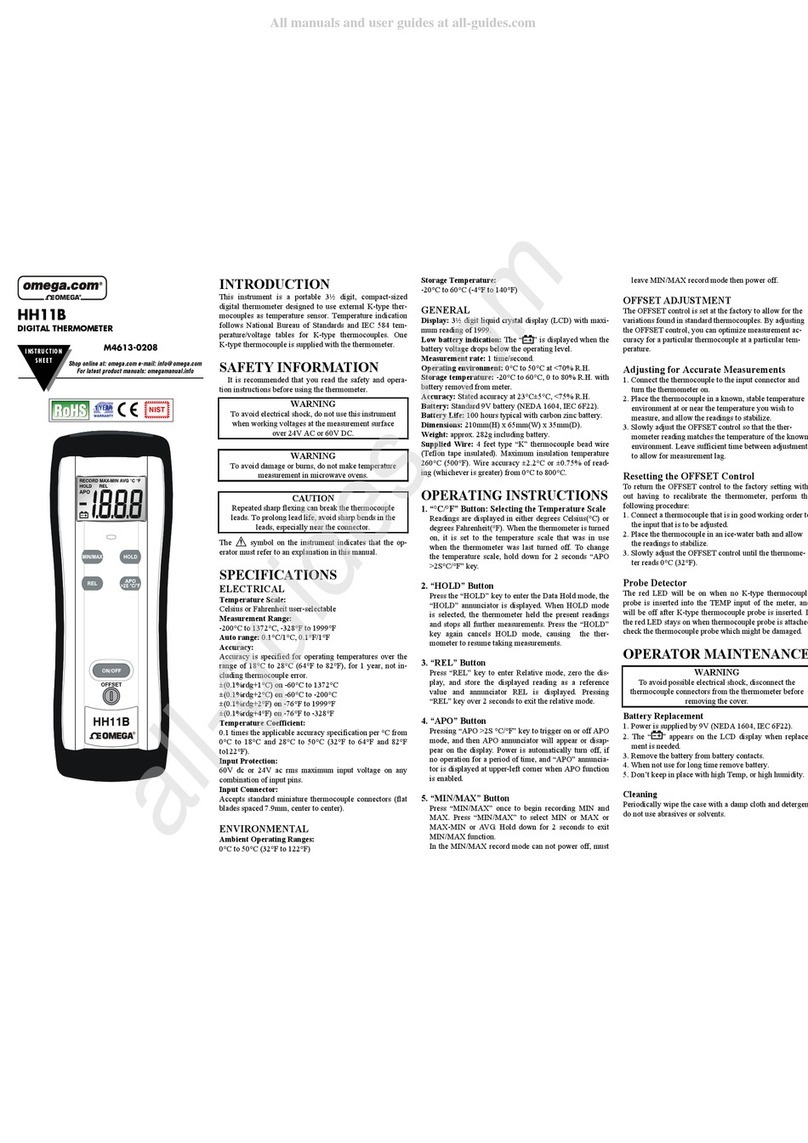

3.1 Safety Precaution and Notes..............................................................................................2

3.2 Control and Display ..................................................................................................................2

3.3 Operating Procedure................................................................................................................3

3.4 Accuracy Considerations ....................................................................................................4

3.5 Three Wire and Four Wire Operations......................................................................4

SECTION 4 THEORY OF OPERATION......................................6

4.1 Three Wire Signal Conditioning ......................................................................................6

4.1.1 Zero Phase........................................................................................................................................6

4.1.2 Signal Phase ....................................................................................................................................7

4.2 Four Wire Signal Conditioning..........................................................................................9

4.2.1 Zero Phase........................................................................................................................................9

4.2.2 Signal Phase ..................................................................................................................................10

4.3 Analog-to-Digital (A/D) Converter ..............................................................................11

4.4 Polarity Detector..........................................................................................................................11

4.5 FET Drivers........................................................................................................................................11

4.6 Low-Battery Detector ............................................................................................................12

SECTION 5 SERVICE INFORMATION......................................12

5.1 Disassembly ..................................................................................................................................12

5.2 Calibration ....................................................................................................................................14

5.3 Probe Compensation ..............................................................................................................16

5.4 Troubleshooting..........................................................................................................................16

5.4.1 Voltage Checks ..........................................................................................................................17

5.4.2 A/D Converter Checks ........................................................................................................17

5.4.3 Waveform Checks....................................................................................................................18

5.5 Static Sensitive Parts ..............................................................................................................19

5.6 Performance Verification ....................................................................................................19

SECTION 6 SPECIFICATIONS ................................................21

6.1 Parts List for Models 868 and 869..............................................................................24