Omega HH81A User manual

Other Omega Thermometer manuals

Omega

Omega OS418L User manual

Omega

Omega OS449L-30 User manual

Omega

Omega HH40 Series User manual

Omega

Omega HH501AE User manual

Omega

Omega HH501AJ User manual

Omega

Omega OS550A User manual

Omega

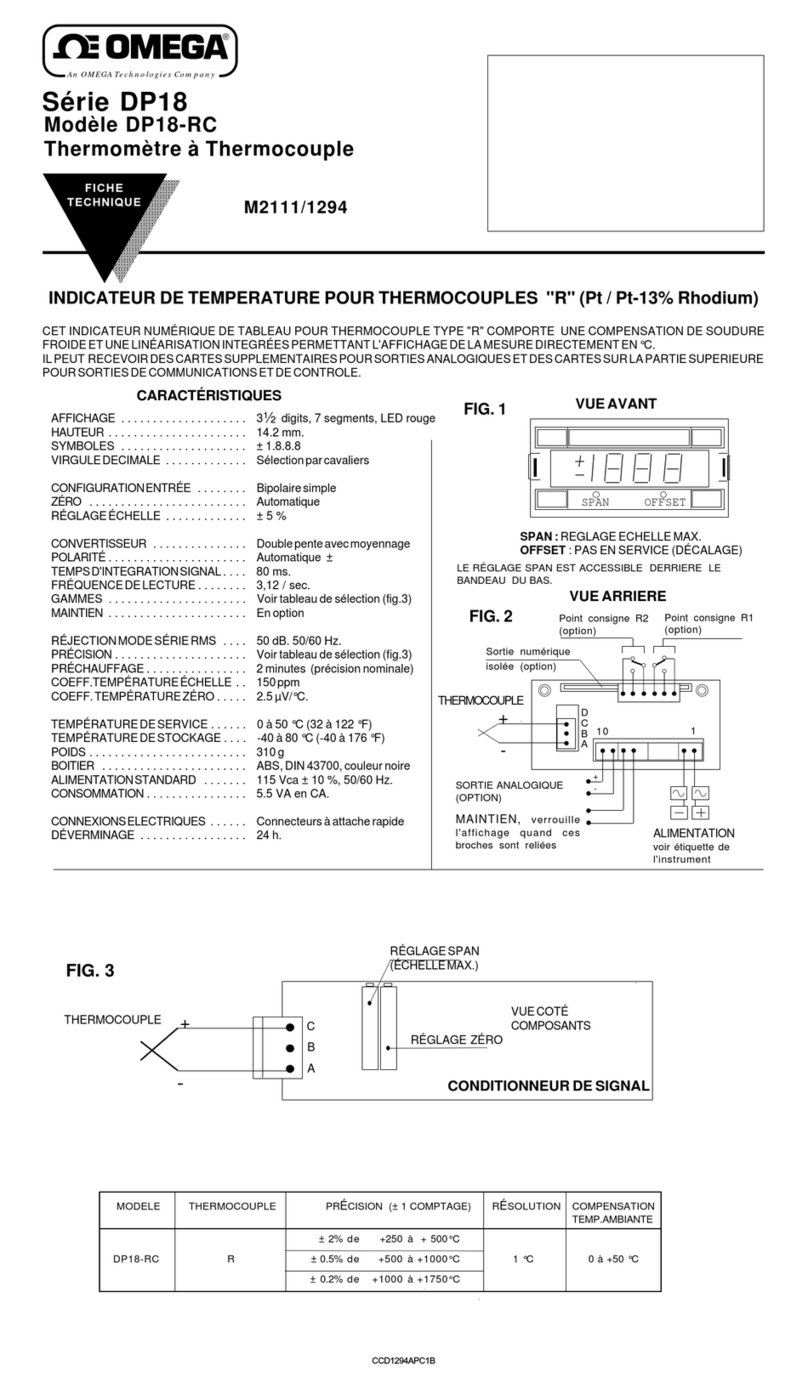

Omega DP18-RC User manual

Omega

Omega HHTFO User manual

Omega

Omega OS643W User manual

Omega

Omega OS642C-LS User manual

Omega

Omega Omegaette OS-FS User manual

Omega

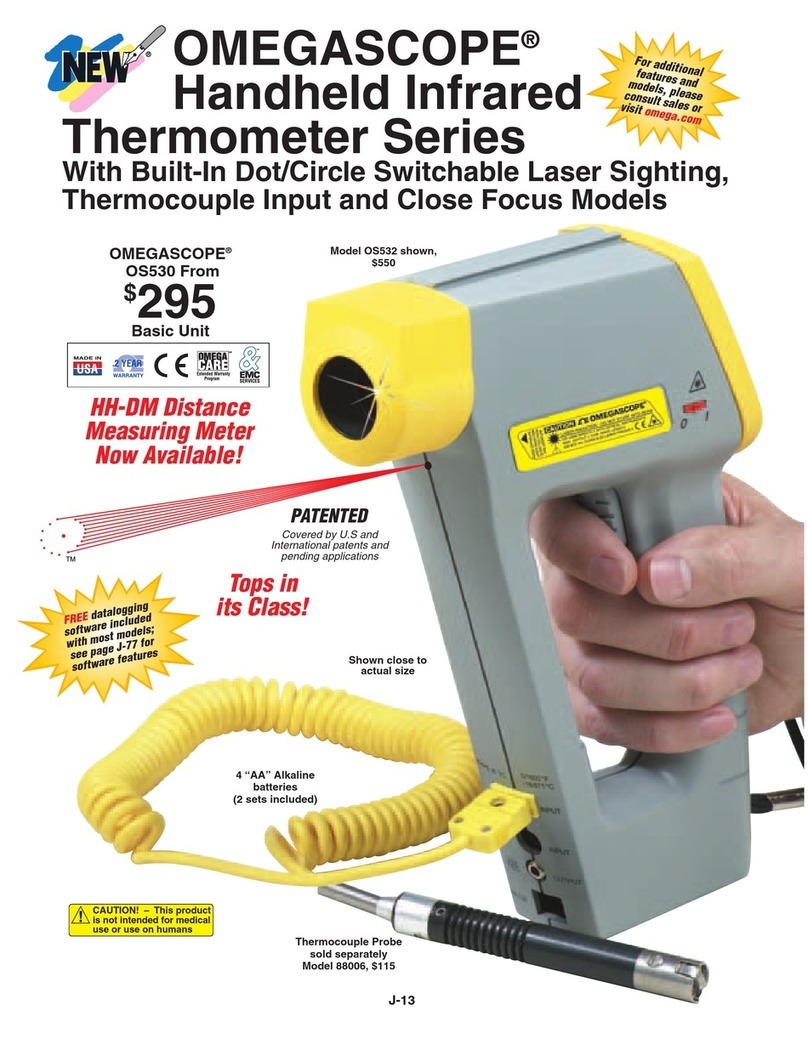

Omega OMEGASCOPE OS532 User manual

Omega

Omega 865 User manual

Omega

Omega HH68K User manual

Omega

Omega HH127 User manual

Omega

Omega CL940A User manual

Omega

Omega HH376 User manual

Omega

Omega HH370 User manual

Omega

Omega HHM29-IR Supermeter Installation and operating instructions

Omega

Omega HH-2000 SERIES User manual