CSM_H8PS_DS_E_6_2

1

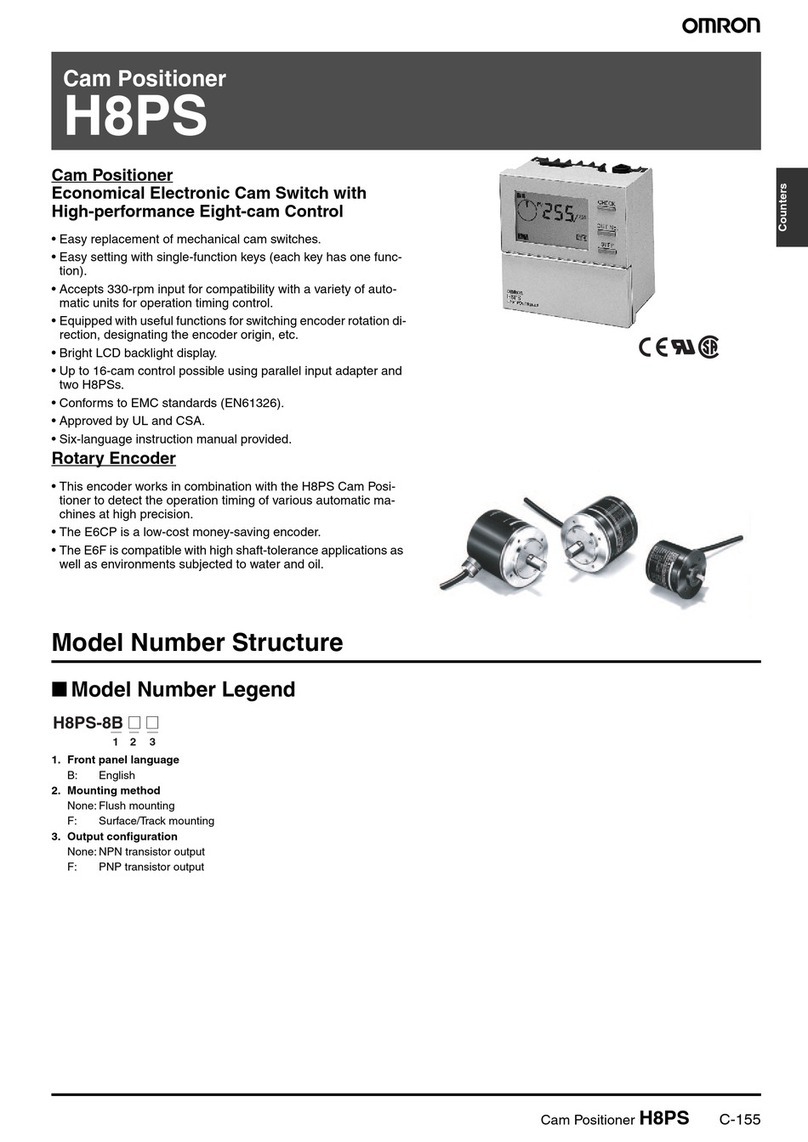

Cam Positioner

H8PS

This Compact Cam Positioner, Popular for Its

Ease-of-use, Now Comes with Even Better

Functions.

• Compact 8-, 16-, and 32-output Models available that are 1/4-

DIN size at 96 x 96 mm.

• High-speed operation at 1,600 r/min and high-precision settings

to 0.5°ensure widespread application.

• Highly visible display with backlit negative transmissive LCD.

• Advance angle compensation function to compensate for output

delays.

• Bank function for multi-product production (8 banks).

(H8PS-16@/-32@models.)

• Speed display and pulse output.

• Approved standards: UL/CSA and EMC.

Refer to Safety Precautions for All Counters and

Safety Precautions on page 18 and 19.

Features

Models with 8, 16, or 32 Outputs

The lineup includes Models with 32 outputs in a compact 1/4-DIN

size. Using the optional Parallel Input Adapter (Y92C-30) enables

expanding to up to 64 outputs for one encoder to support anything

from a simple positioning application to a large-scale system.

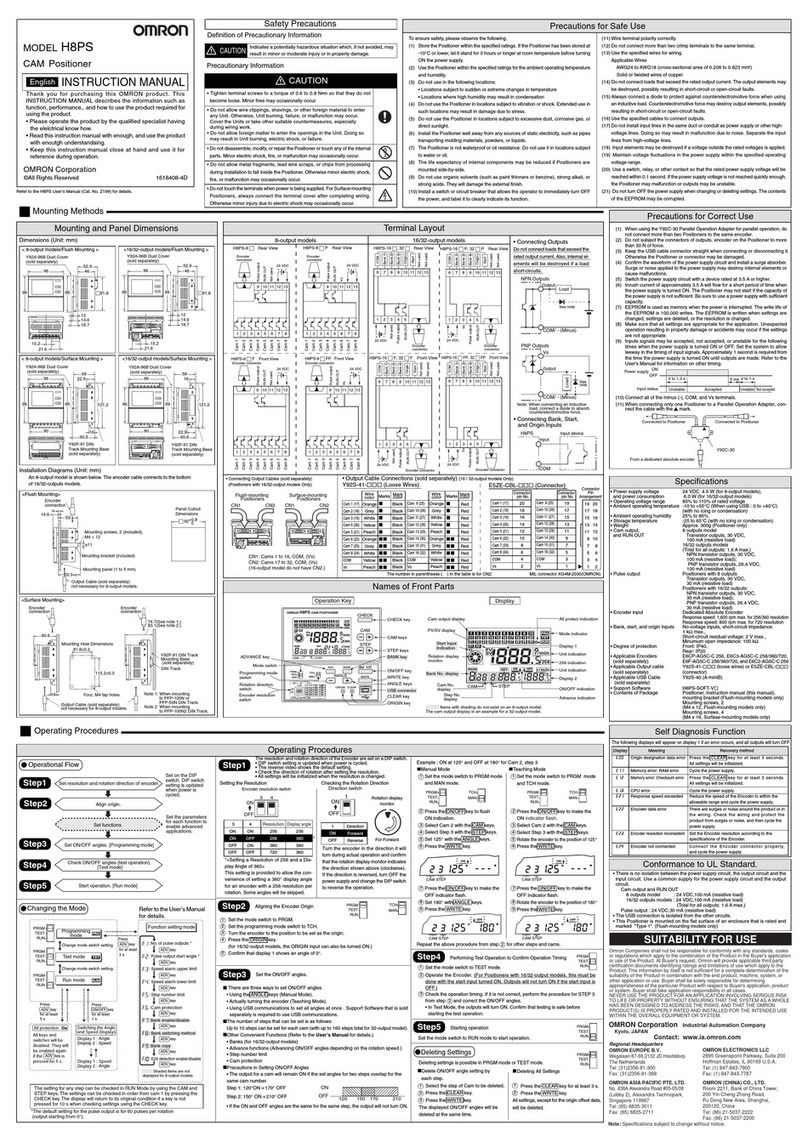

Simple Programming

The programming method is designed based on a one key-one

action concept for settings that could not be simpler. Both initial

settings and factory adjustments are effort-free.

Large, Backlit Negative LCDs

Large LCDs, red for the process value and green for set values, show

a wealth of operation information, making operating status visible at

a glance.

High Speed Up To 1,600 r/min

High Precision Up To 0.5°(at 720 Resolution)

High-speed, high-precision applications can be easily handled and

productivity increased.

Bank Function for Multi-product Production

Up to eight different programs can be registered in advance to

enable fast and easy switching between products (16/32-output

Models only).

USB Communications for Easy Setting from

a Computer

Optional Support Software can be used to enable programming from

a personal computer via USB communications. Programs can be

easily copied, saved, printed, and much more.

Speed Display and Speed Alarm Output

Both the speed (rotations/minutes) and present angular position can

be displayed at the same time. Alarm outputs can be produced for

both upper and lower speed limits.

Advance Angle Compensation Function to

Compensate for Output Delays

The advance angle compensation (ADV) function automatically

advances the ON/OFF angle of outputs in proportion to machine

(encoder) speed to compensate for the delay in timing of ON/OFF

operation. ADV values can be set individually for 7 cam outputs.

Pulse Output for Timing Control

The number of pulses per rotation and the pulse output start angle

can be set to enable operations like adjusting timing with a PLC or

outputting to a rotation meter.

8-output Models 16-output Models 32-output Models

96 mm

96 mm

CAM STEP

12 7

RUN

CAM STEP

12 7

RUN

Switchable

Present angular

position

Speed

Speed

Present angular

position

Speed

Upper limit

alarm output

Lower limit

alarm output

Upper limit

Lower limit

Errors

Cam program settings

100°

8°compensation 180°

92°172°

At high-speed (400 r/min)

Pulse outputPLC

Rotation meter