Connection manual of XDesignerPlus external devices

6. Support address

The device which is available at TOP is as follows.

There can be a device range difference according to the module series/type of CPU. Refer to the user's manual of each CPU module.

Be careful not to be out of the address range that the relevant device supports

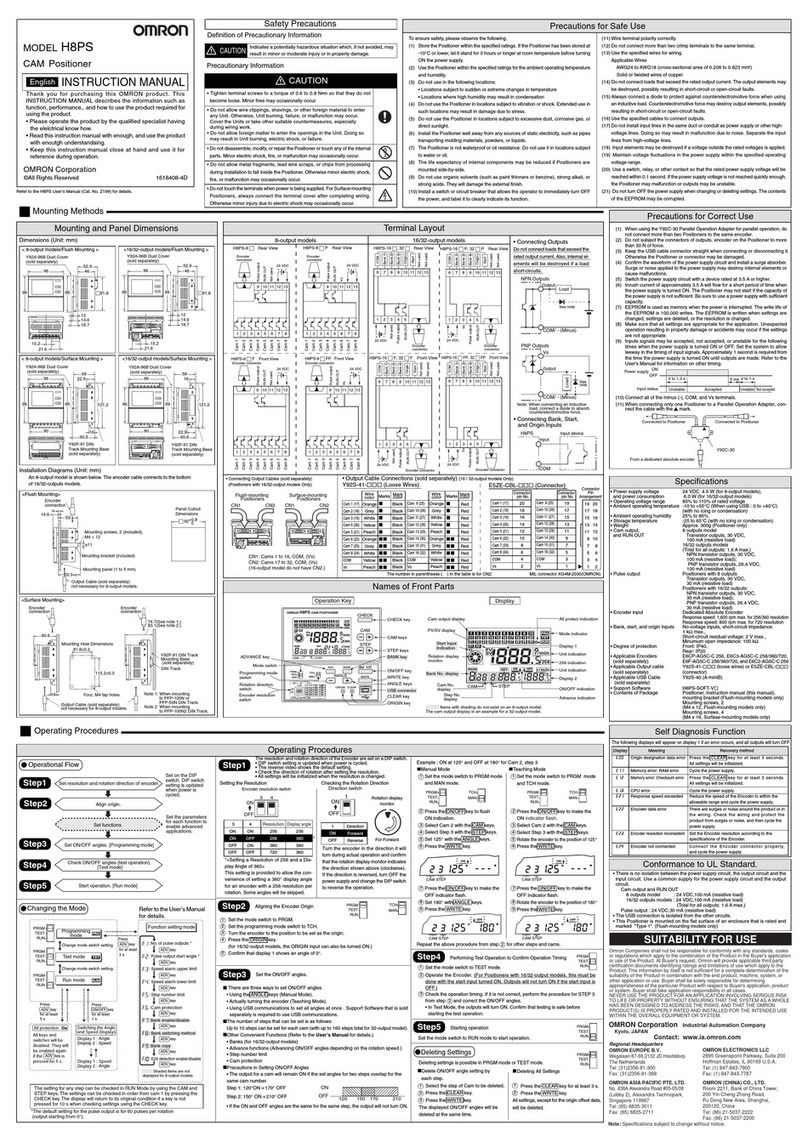

- Memory Area Read (RUN) : M

Current Resolver Speed (r/min) : 4-digit BCD

Address 0000 : Leftmost byte / Address 0001 : Rightmost byte

Present cam angle (in set unit) : 4-digit BCD

Address 0002 : Leftmost byte / Address 0003 : Rightmost byte

Cam output status

0 : Output OFF / 1 : Output ON

Address 0007 : CAM1~8 / Address 0006 : CAM9~16

Address 0005 : CAM 17~24 / Address 0004 : CAM 25~32

Executing bank NO. : 2-digit BCD

*Note1)The 8 digits can be read when the M0008 address uses 32BIT device.

- Parameter Area Read / Write (SET) : P

Resolution /

Compensation

Settings

Resolution selection, and the presence or absence of backlash and advance angle

compensations.

Origin

Compensation

value

Origin compensation value : 4-digit BCD from 0000 to 0359 (0719)

Address 0002 : Leftmost byte / Address 0003 : Rightmost byte

Backlash

Compensation

value

Backlash compensation value : 4-digit BCD from 0000 to 0359 (0719)

Address 0004 : Leftmost byte / Address 0005 : Rightmost byte

Advance Angle

Compensation

Value 1

Advance angle compensation value 1 : 4-digit BCD

Address 0006, 0007 : Speed data 0000 to 1600 (0800)

Address 0008, 0009 : Angle data 0000 to 0359 (0719)

Advance Angle

Compensation

Value 2

Advance angle compensation value 2 : 4-digit BCD

Address 000A, 000B : Speed data 0000 to 1600 (0800)

Address 000C, 000D : Angle data 0000 to 0359 (0719)

Advance Angle

Compensation

Value 3

Advance angle compensation value 3 : 4-digit BCD from 0000 to 0359 (0719)

Address 000E : Leftmost byte / Address 000F : Rightmost byte

Bank 1 Cam

Data Protect

Setting

Cam data protect setting

0 : Not protected / 1 : Protected

Address 0013 : CAM1~8 / Address 0012 : CAM9~16

Address 0011 : CAM 17~24 / Address 0010 : CAM 25~32

Bank 1 One-

direction

Function Setting

One-direction function setting

0 : OFF / 1 : ON

Address 0017 : CAM1~8 / Address 0016 : CAM9~16

Address 0015 : CAM 17~24 / Address 0014 : CAM 25~32

Bank1 Rotation

Direction Setting

Rotation direction setting

0 : Forward / 1 : Reverse

Address 001B : CAM1~8 / Address 001A : CAM9~16

Address 0019 : CAM 17~24 / Address 0018 : CAM 25~32