DX-6630)

DX-6630

| |

2.

Warning

lable

|

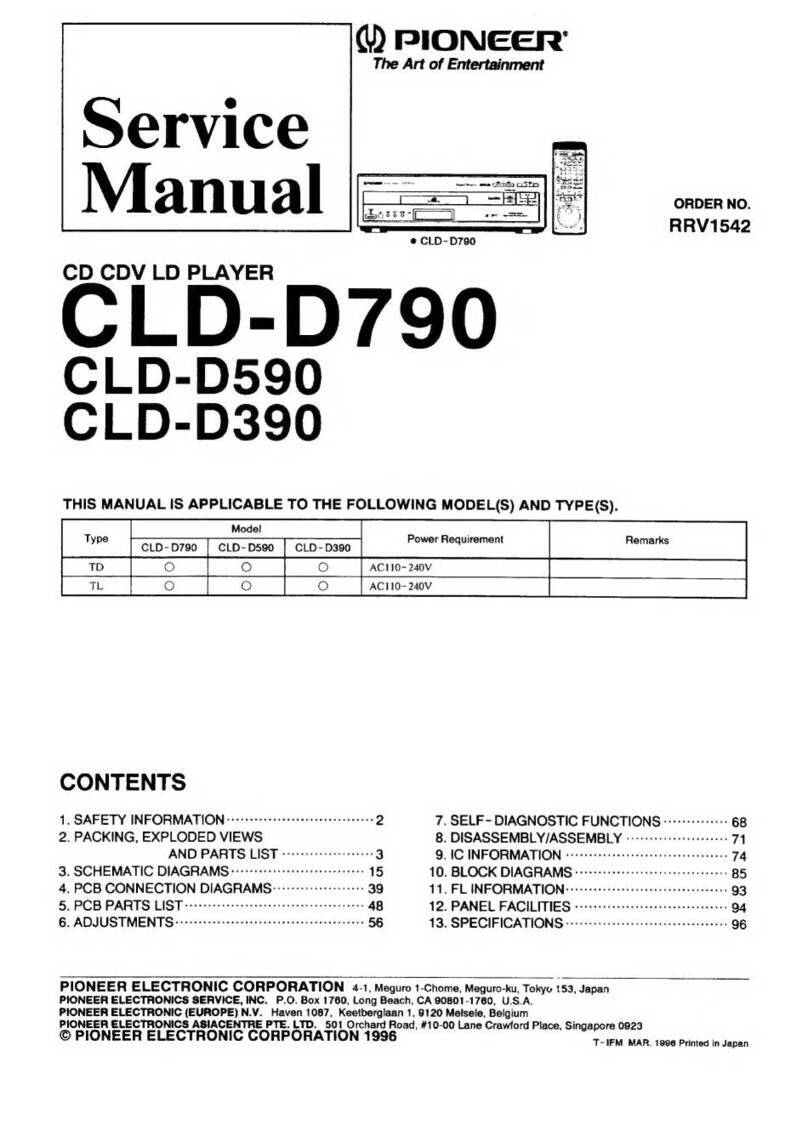

TABLE

OF

CONTENTS

This

label

is

located

on

the

arm

of

mechanism.

SPSCIHCAIONS

1)

ace

tin

me

aa

eel

add

ae

eae

]

Portection

on

eyes

from

laser

beam

during

servicing...

.

.

z

Laser

warning

labels...

2.0...

2

2

ee

ee

ee

eee

2

Caution

on

replacement

of

pickup

.............-..

4

Exploded

view-parts

list...

0.02...

ee

ee

eee

4

Exploded

View

acs

oh

ooh

goes

Se

eee

eae

eas

5

Mechanism-exploded

view.................--06-

6

PAROS

iG

a

atau

Oc

tak

Oiute

eoes

ee

Whee

ate

3a

7

Disassembling

i

os

Seiiksase

SRecbeeh

hateas

deauare

:

DANGER

=

iNvisiBLe

fase

RADIATION

Adjustment

procedures...........

ts

sata

sc

taney

Assis

Bk

Trouble

shooting

guide...

...............22005

15

AUT

10

i.

DIRECT

EXPOSURE

TO

BEAM

IC

block

diagram

and

description................

17

HW.

—HAZARDOUS

LASER

AND

se

PGSCHIDUONS

4-5.

eat

ee

en

edie

es

a5

ANDINTEFLOCK

DEFEATED

ee

chematic

diagram.

......

ity

hese

ens

eens

Bates

TTENTION

—RAYONNEMENT

ate

Waveform

of

each

section...

..........2.00000-

29

ET

ELECTROMAGNETIQUE

DANGEREUX

SI

Pc

board

view

&

Parts

list...

2...

eee

ee

ee

eee

31

OUVERT

AVEC

L’ECLENCHEMENT

OF

SECURITE

Block

diagram...

0.00.

ee

eee

eee

35

ANNULE.

$N29360911

PACKING

VIEW

ica

Oct

ow

Shere

eee

td

ed

ae

wee

36

ADVARSEL:

USYNLIG

LASERSTRALING

VED

ABNING,

NAR

SIKKERHEDSAF-

BRYDER

ER

UDE

AF

FUNKTION.

UNDGA

UDS/ETTELSE

FOR

STRALING.

Photo

1

Fig.

4

PROTECTION

OF

EYES

FROM

LASER

BEAM

DURING

SERVICING

This

set

employs

a

laser.

Therefore,

be

sure

to

follow

Laser

Diode

Properties

carefully

the

instructions

below

when

servicing.

©

Material:

GaAS/GaAlAs

ADVARSEL

ic

pNINGH

@

Wavelength:

780nm

nt

@

Emission

Duration:

continuous

;

eee

fia

Denne

merkning

er

anbragt

pa

apparatets

h@jre

side

og

indikerer

WwW

: ;

V

J

h

.

.

*

;

e

elder

ae

pee

Ret

AE

RODE

THE

TASES

sa)

held

dae

max:

Oy

at

apparatet

arbejder

med

laserstraler

af

klasse

1,

hvilket

betyder

E

TOO

CLOSELY.

IN

CASE

IT

IS

*This

output

is

the

value

measured

at

a

distance

“CLASS

1

LASER

td

dpe

|

3

:

‘

NECESSARY

TO

CONFIRM

LASER

BEAM

EMMISION,

about

1.8mm

from

the

objective

lens

surface

PRODUCT”

at

der

arwendes

laserstrater

af

svageste

klasse,

og

at

man

ikke

p&

BE

SURE

TO

OBSERVE

FROM

A

DISTANCE

OF

MORE

on

the

Optical

Pick-up

Block.

|

|

apparatets

yderside

kan

blive

udsat

for

utilladelig

kraftig

straling.

THAN

30cm

FROM

THE

SURFACE

OF

THE

OBJECTIVE

LENS

ON

THE

OPTICAL

PICK-UP

BLOCK.

APPARATET

BOR

KUN

ABNES

AF

FAGFOLK

MED

SARLIGT

KENDSKAB

TIL

APPARATER

MED

LASERSTRALER!

LASER

WARNING

LABEL

The

label

shown

below

are

affixed.

|

Indvendigt

i

apparatet

er

anbragt

den

her

gengivne

advarselsmerk-

1.

Class

1

label

(Except

120V

model)

ning,

som

advarer

imod

at

foretage

sadanne

indgreb

i

apparatet,

at

This

label

is

located

on

the

back

panel.

;

:

Pp

man

kan

komme

til

at

udsztte

sig

for

laserstraling.

AOVARSEL

USYNLIG

LASERSTRALING

VEO

ABNING,

NAR

SIKKERHEOSAF

BRYOER

ER

UDE

AF

FUNKTION

UNDGA

UDSATTELSE

FOR

STRALING

VAROITUS!

Laite

sisaltaa

laserdiodin,

joka

lahettaa

(nakyma-

tonta)

silmitle

vaarallista

lasersateilya.

“CLASS

1

LASER

PRODUCT”

Fig.

3