ONLINE ELECTRONICS LTD

3014X ATEX EM TRANSMITTER MANUAL RevB00 Page 9 of 16

3.6. INSTALLATION

1. All EM transmitters will induce electrical currents in any conductive materials closely

surrounding them which can result in a severe reduction in signal strength and/or battery

lifetime. This effect can be minimised by reducing the amount of conducting material

surrounding the transmitter. Leave as much of the transmitter exposed as possible. Any

slits or apertures which can be made in the surrounding material will help. Use materials

with as high resistance as possible. Non-conducting materials such as plastics will not

suffer from this effect. EM transmitters must not be surrounded by low resistance metals

such as aluminium (including tubes or mounting clamps) under any circumstances.

2. Any magnetic material surrounding the transmitter will tend to block the EM signal from

the transmitter and reduce the received signal strength outside the pipeline. This effect can

be minimised by reducing the amount of magnetic material surrounding the transmitter.

Leave as much of the transmitter exposed as possible. Any slits or apertures which can be

made in the surrounding material will help. Use materials with as low magnetic

permeability as possible. Non-magnetic materials such as plastics will not suffer from this

effect.

3. The transmitter must be mounted in such a way that no movement or vibration

whatsoever is possible (e.g. clamped). If the transmitter is allowed to rattle and/or vibrate

within the pig then the resultant hammering effect can exceed the bump rating of the

transmitter leading to damage and/or failure. This is particularly important in gas pipelines.

For optimum performance the transmitter should be clamped inside a plastic pig body or

plastic guide discs should be clamped around the transmitter to form a pig. The advantage of

these methods is the fact that there is no metal around the transmitter apart from the pipeline

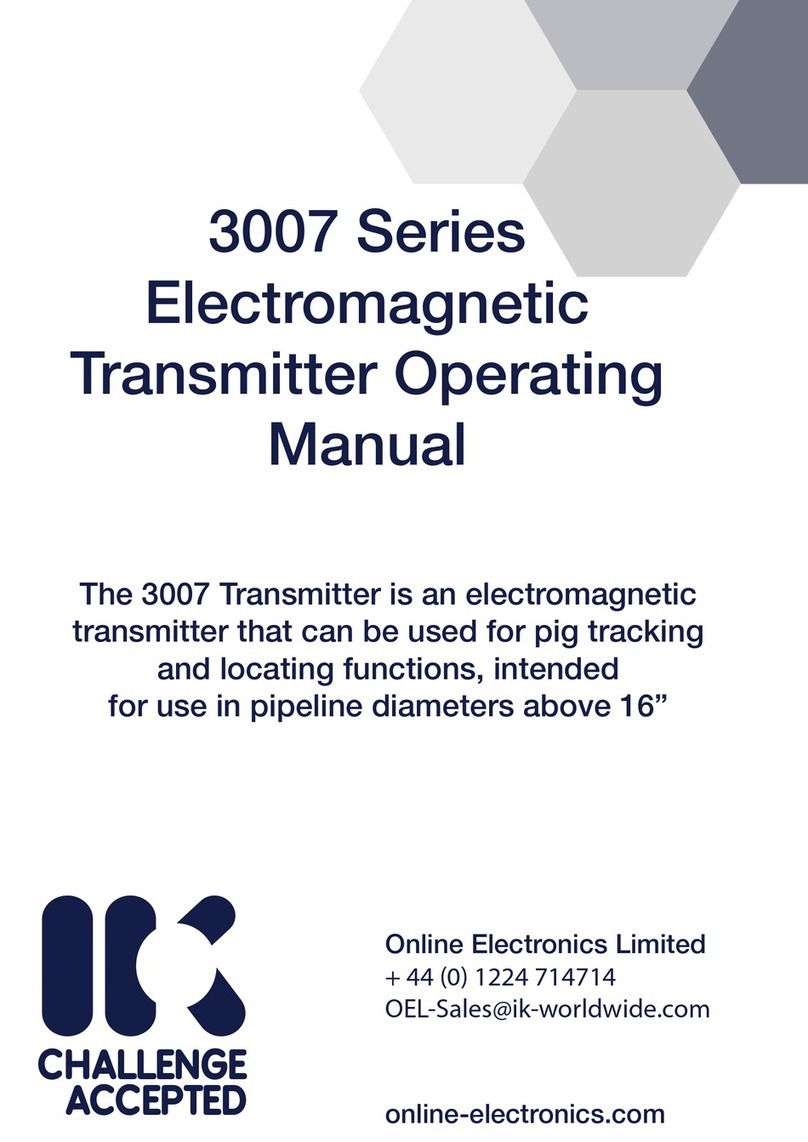

itself. Two alternative mounting arrangements are shown below. The first uses several lengths

of threaded studding to clamp the transmitter between two plates. The second uses a clamping

disc. The advantage of these arrangements is that they have limited amounts of metal around

the transmitter and will therefore have limited effect on the transmitter performance. Please

contact Online Electronics for further information and guidelines regarding EM transmitter

mounting and installation.

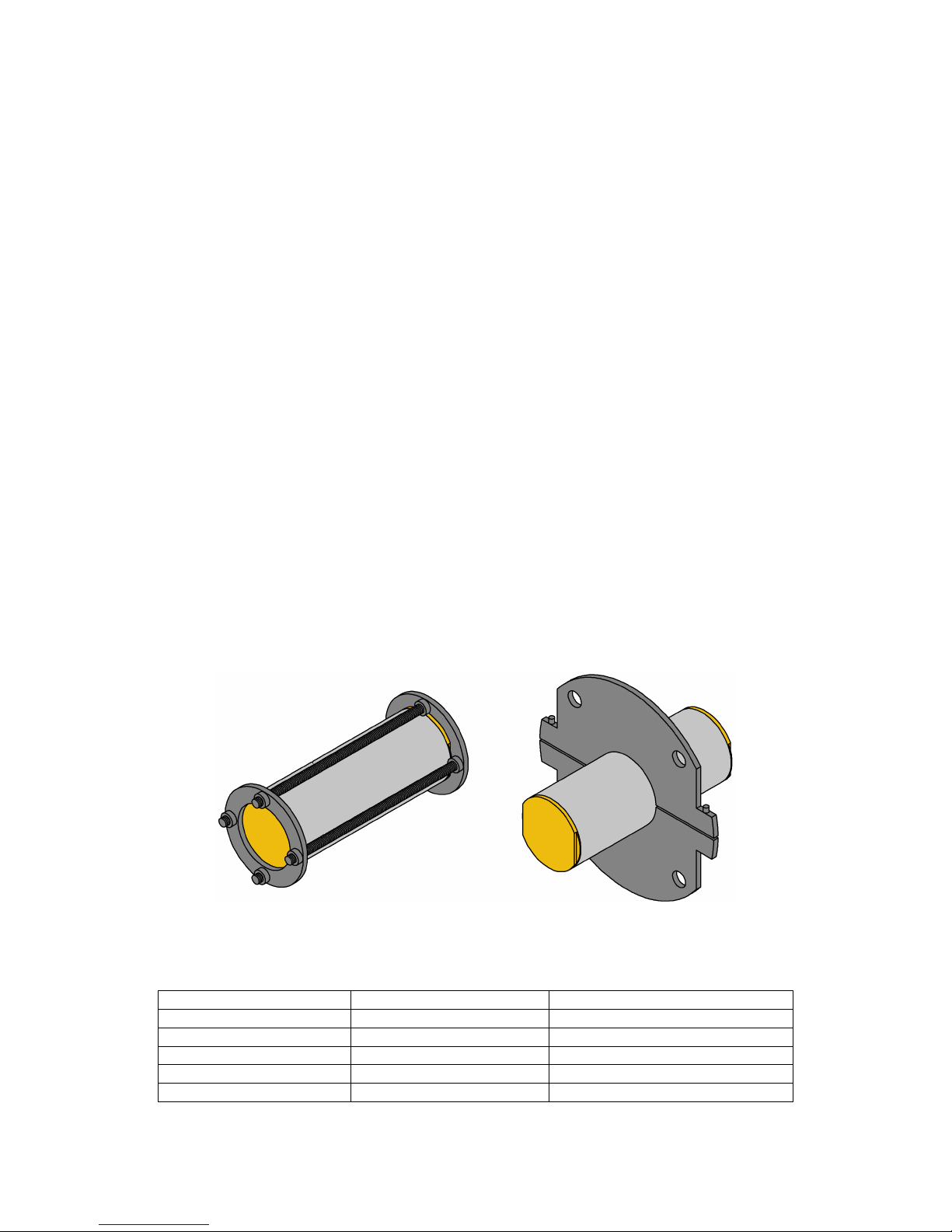

The table below shows the typical characteristics of several potential pig and mounting

materials with the best choice at the top, and the worst choice at the bottom. 316 stainless

steel provides a good balance of properties and cost. An aluminium alloy would be a very poor

choice because of the very low resistivity and should not be used under any circumstances.