ONLINE ELECTRONICS LTD

2405_5001_A01 Page 6 of 14

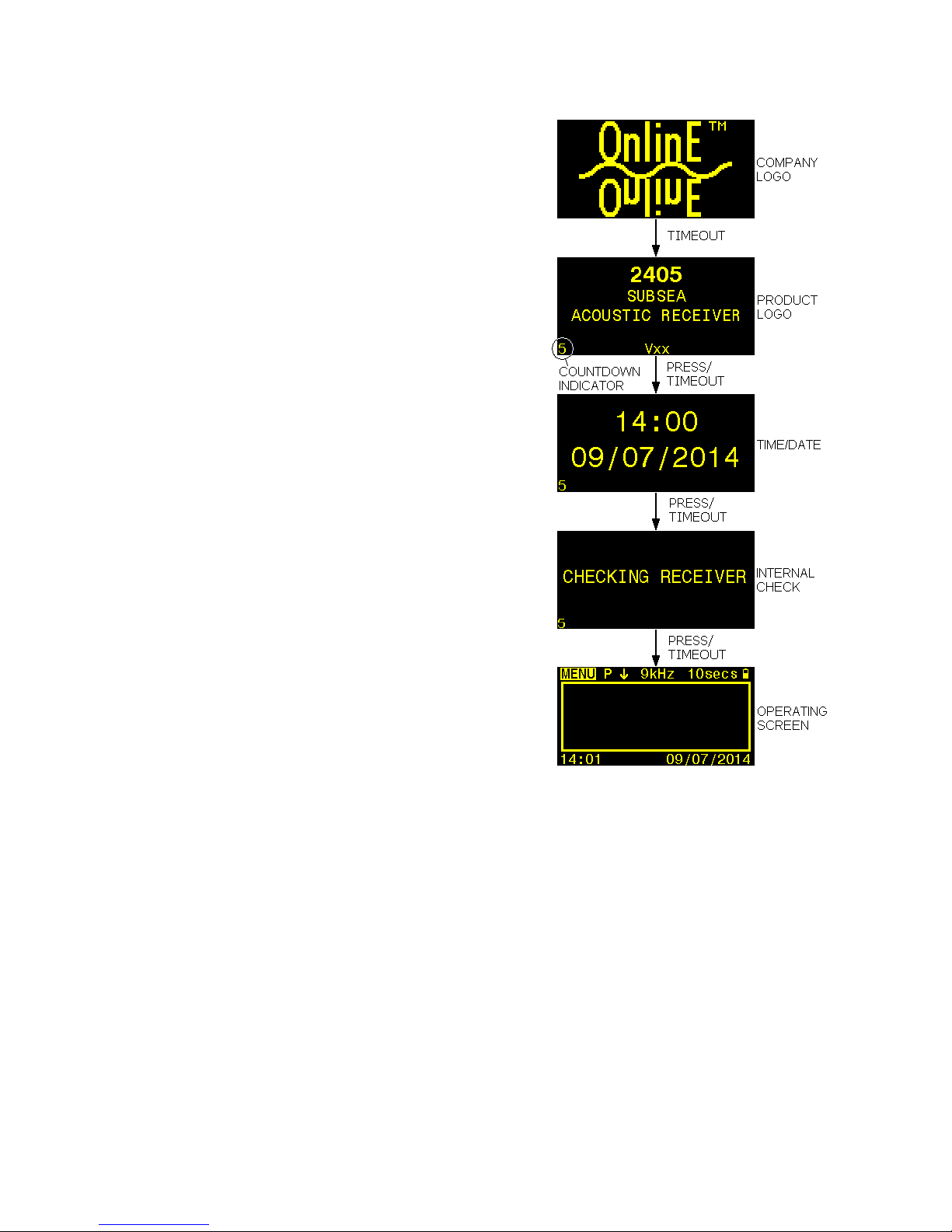

3. OPERATION

As with all acoustic systems, the ambient acoustic noise existing in the environment will have a

significant impact on the performance of the 2405 system. Some of the most common sources

of ambient acoustic noise are vessel engines, water turbulence and rough weather.

Also be aware that there may be nearby acoustic transmitters unexpectedly transmitting at (or

close to) the frequency of interest. These should be disabled if possible. For example any

acoustic beacons on the ROV must be disabled and any support vessels with dynamic

positioning systems should be disabled or configured to work outside of the frequency of

interest if possible.

The typical procedure for detecting an acoustic transmitter is given below. This procedure

assumes the operator knows the expected frequency and pulse rate of the acoustic transmitter

being searched for.

1. Before each deployment visually inspect all system components to ensure that they are

secure and undamaged. Pay particular attention to the cable and connectors.

2. Before each deployment ensure that all tests described in section 3.1 SELF TEST and

section 3.2 FUNCTION TEST are repeated.

3. Before deployment ensure the fishtail is positioned suitably, it can be positioned in several

different positions on the fishtail bracket as required.

4. Use the control button to select the expected frequency of the acoustic transmitter.

5. It is recommended that AGC gain is selected as per section 3.5.2 MANUAL MODE / AGC

MODE.

6. Select a timebase which will display approximately 5 pulses at the expected repetition rate

on the screen as per section 3.4 OPERATING SCREEN.

7. Ensure the unit is turned on as per section 3.3 TURNING ON and the battery meter shows

more than 50% capacity remaining. If less than 50% is indicated then change the

batteries as per section 4.1 BATTERY REPLACEMENT.

8. Point the active face of the 2401 hydrophone towards the expected location of the acoustic

transmitter. The active face of the 2401 points out of the tubular frame in the opposite

direction to the 2405 display.

9. Very slowly scan in different directions while observing the signal received and the AGC

value to try and determine which direction gives the strongest and clearest signal. Move in

this direction to get as close as possible to the transmitter.

10. Confirm that the FREQUENCY and pulse rate of the acoustic signal are as expected. Be

aware that there may be other acoustic transmitters in the environment (such as ROV

beacons or dynamic positioning beacons). These sources should be disabled if possible

otherwise it should be possible to identify the signal of interest by carefully examining

frequency and pulse rate.