FRONT SUSPENSION 3A- 9

8. Press ball stud out of lower control arm.

Removal Opel 1900

-

Manta

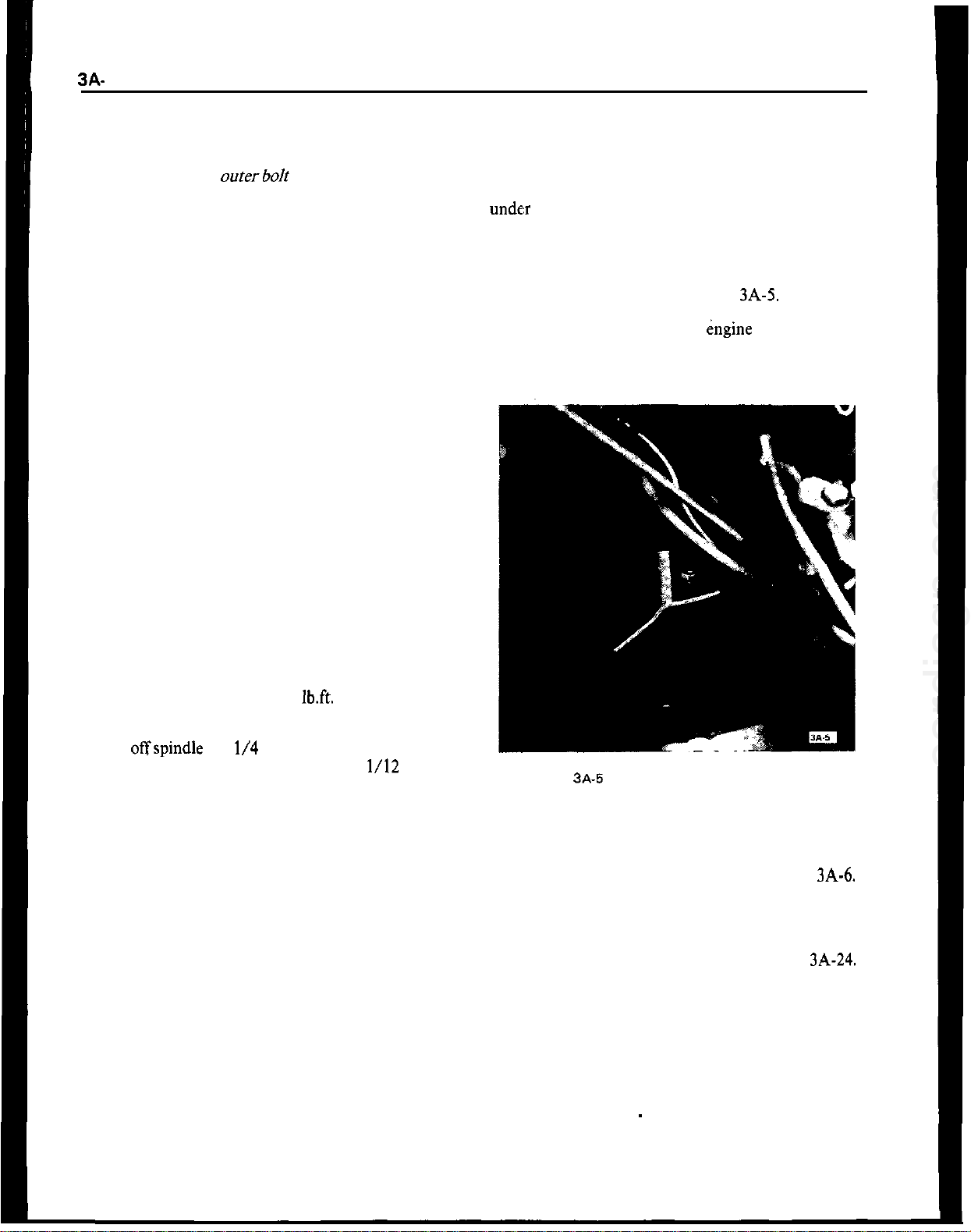

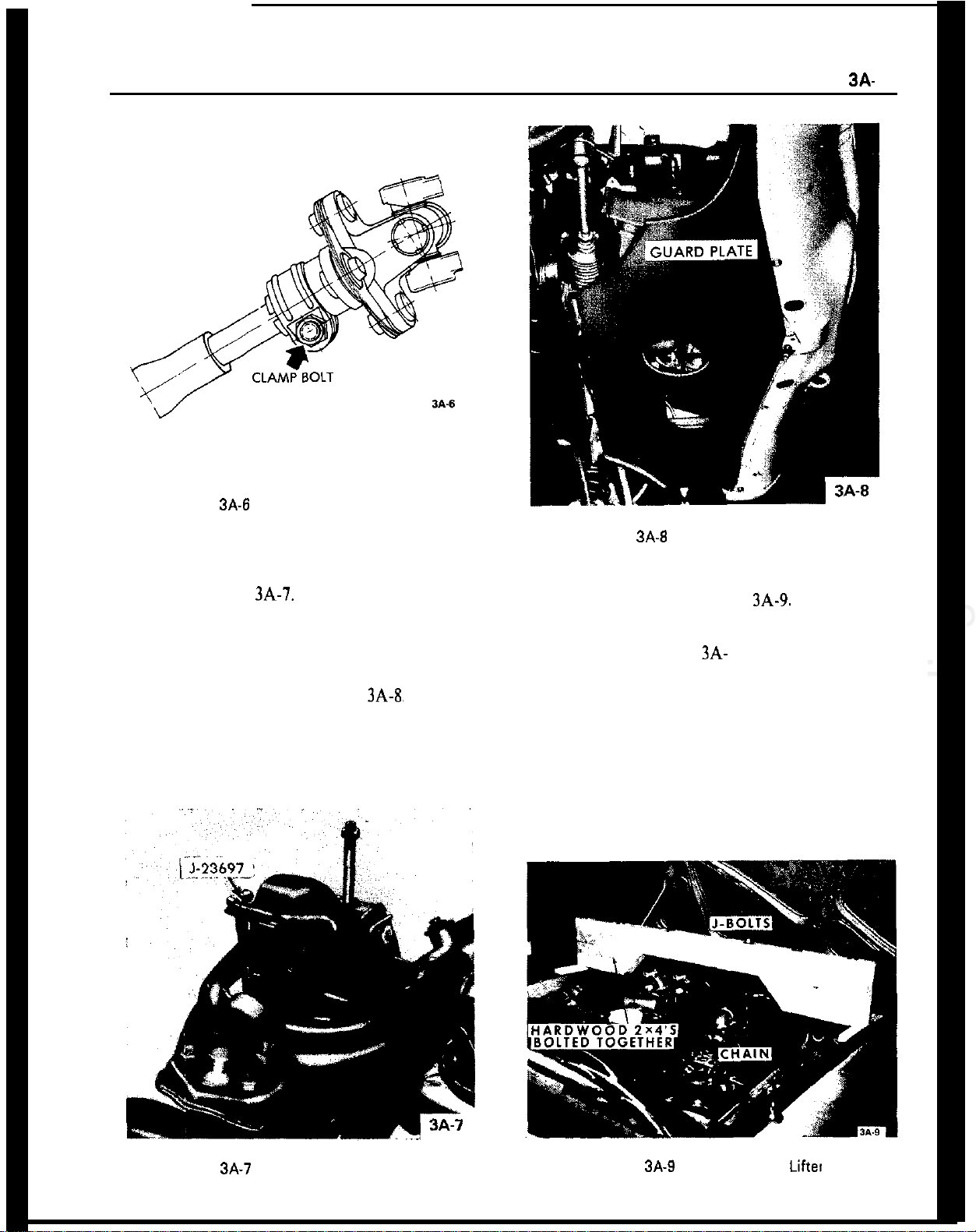

Before raising vehicle, install Hooks J-23697 on re-

spective vehicle side to cross member and upper con-

trol arm. See Figure 3A-7.

1. Raise car and support at rear of front frame rails.

2. Remove front wheel.

3. At the lower control arm ball joint, remove castle

nut cotter pin and slacken back nut so that the thread

can no longer be damaged.

4. With a suitable drift, detach ball joint from steer-

ing knuckle. With jack, lift up lower control arm,

unscrew castle nut and remove Hooks J-23697.

5. Unscrew upper control arm ball joint and suspend

front wheel hub and brake caliper in wheel house. Do

not turn upper control arm ball joint flange, as this

would result in a change of camber.

6. Remove defective lower control arm ball joint

using Tools J-9519 and Receiver J-23754.

Installation GT

CAUTION:

Fasteners are important attachingparts in

that they could affect the performance of

vitaI

com-

ponents and systems, and/or could result in ma&r

repair expense. They must be replaced with one of

the same part numer or with an equivalent part if

replacement becomes necessary. Do not use a

re-

placement part of lesser quality or substitute design.

Torque values must be used as specified during reas-

sembly to assure proper retention of these parts.

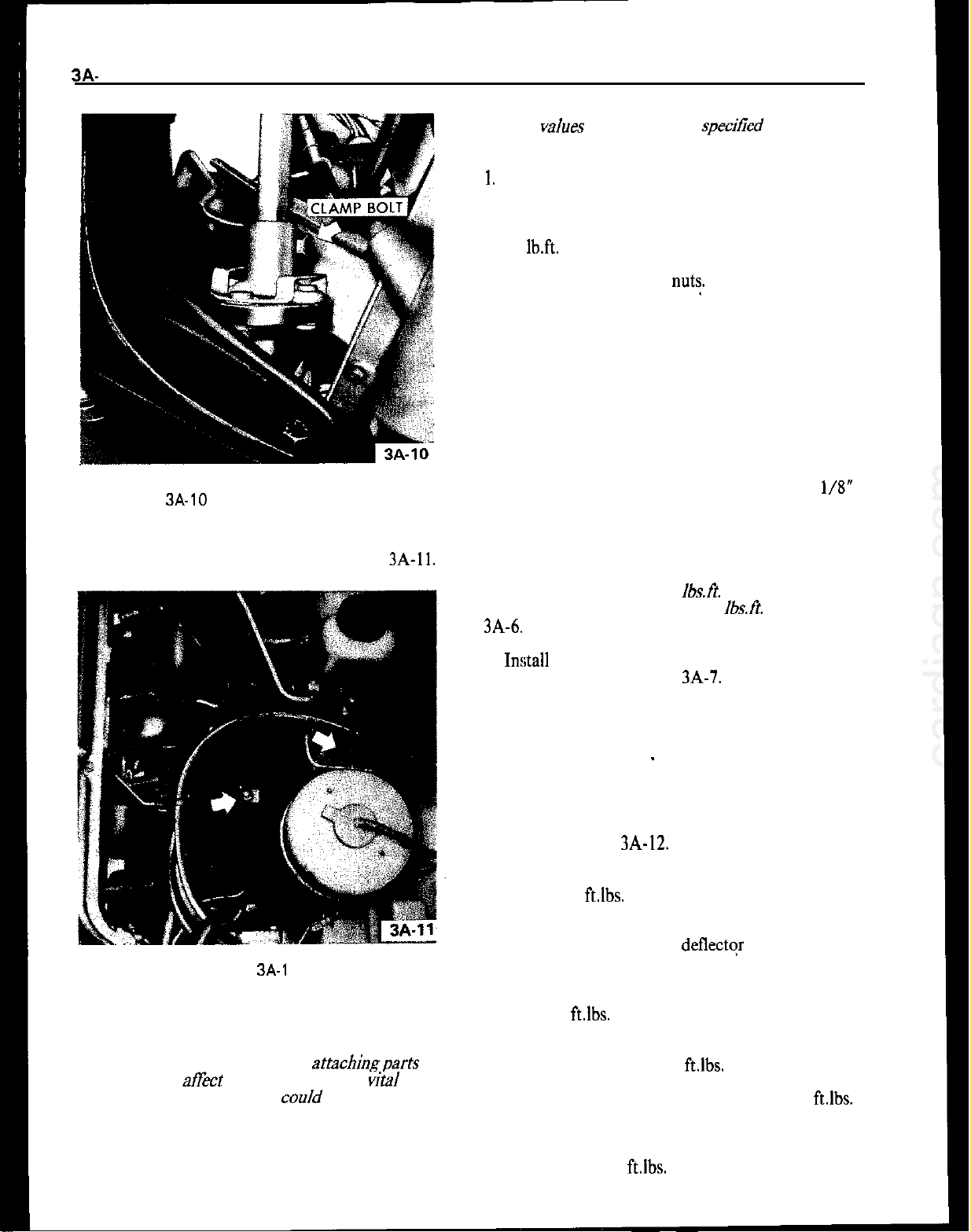

1. When pressing the ball joint in place, make certain

the locating notch in the lower rim of the ball joint

matches the alignment reference mark placed on the

lower control arm prior to removal. The notch in the

ball joint bottom plate, identifying the direction of

the elongated slot, must point towards the brake

drum backing plate. See Figure

3A-17.

Alignment

must be within 2 degrees of lower control arm center-

line. If proper positioning of the ball joint is not

accomplished, the result is a limitation of the neces-

sary ball stud movement. If ball stud movement is

limited, an interference between the ball stud and

housing is created, and binding or even fracture may

occur. Replacement ball joints may or may not have

marking notch as shown in Figure

3A-20.

If it does

not have a marking notch, the joint is completely

symetrical and may be installed in any position.

When pressing in ball joint do not press on bottom

plate, but on ball joint housing only.

2. Install dust cap on lower ball joint and fill with

chassis lubricant. Attach dust cap retainer.

3. Press ball joint into steering knuckle. Use

J-

9519-3 as installer and J-21690 as a supporting

sleeve.

4. Install castle nut on ball joint stud and torque to

40

Ib.ft.

Install new cotter pin.

5. Reconnect shock absorber to lower control arm

and torque to 30 lb.ft.

6. Remove spring compressor.

7. Install front wheel, and lower the car.

8. Always check caster and camber after ball joint

replacement.

Installation Opel 1900

-

Manta

CAUTION:

Fasteners are important attachingparts in

that they could

aff’ect

the performance of vital com-

ponents and systems, and/or could result in ma&r

repair expense. They must be rep/aced with one of

the same part number or with equivalent parts, if

rep/acement

becomes

necessary.

Do not use a

re-

p/acement part of lesser quality or substitute design.

Torque valves must be used as specitied during

reas-

sembIy to assure proper retention of these parts.

1. Drive new ball joint into lower control arm using

Tools J-9519 as installer and J-23755 as a supporting

sleeve. Do not strike onto ball joint bottom.

The ball joint is maintenance-free. It is supplied as an

assembly only and cannot be disassembled further.

2. On new lower control arm ball joint, make sure

that the marking groove in the housing bottom in

alignment with the axis of the lower control arm.

Permissible deviation: minus 2 degrees to plus 2 de-

grees.

This is required, to obtain the maximum freedom of

movement of the ball stud in the housing. See Figure

3A-18.

3. Attach steering knuckle together with front wheel

hub and brake caliper to lower control arm ball joint.

Torque castle nut to 54

ft.lbs.

4. Attach ball joint to upper control arm and torque

to 29

ft.lbs.

Always use new self-locking nuts.

5. Install wheel and tighten nuts to a torque of 65

ft.lbs.

6. Lower car and check caster and camber.