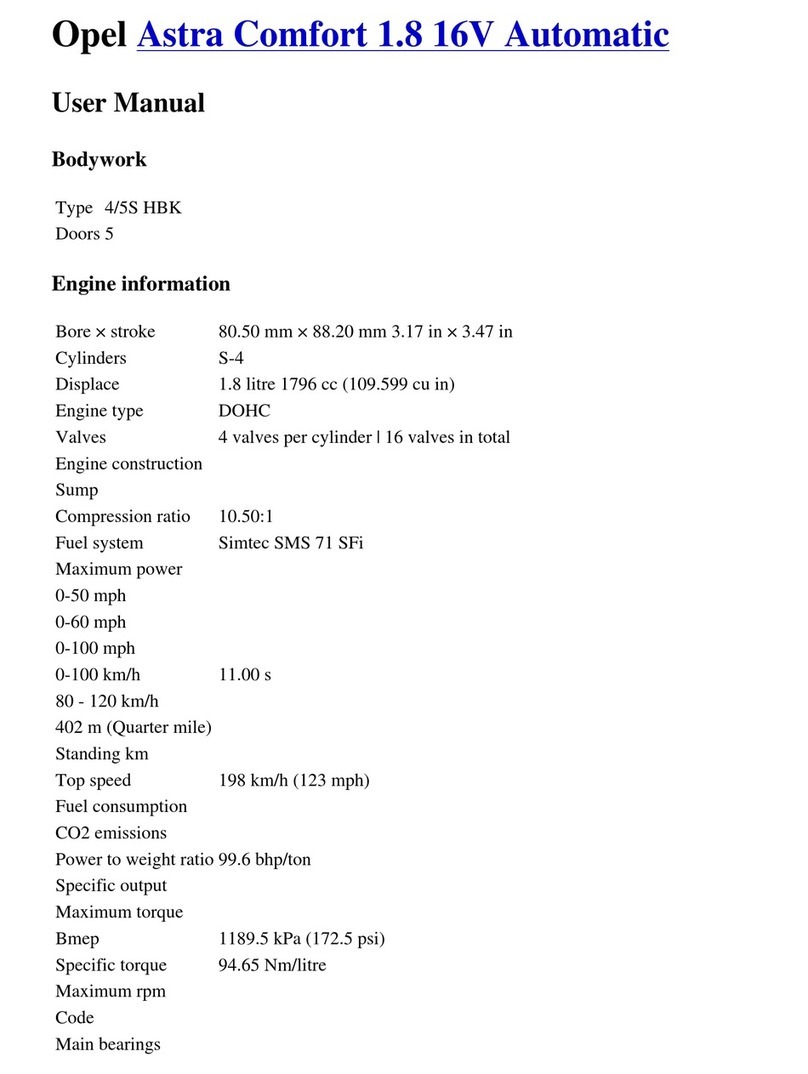

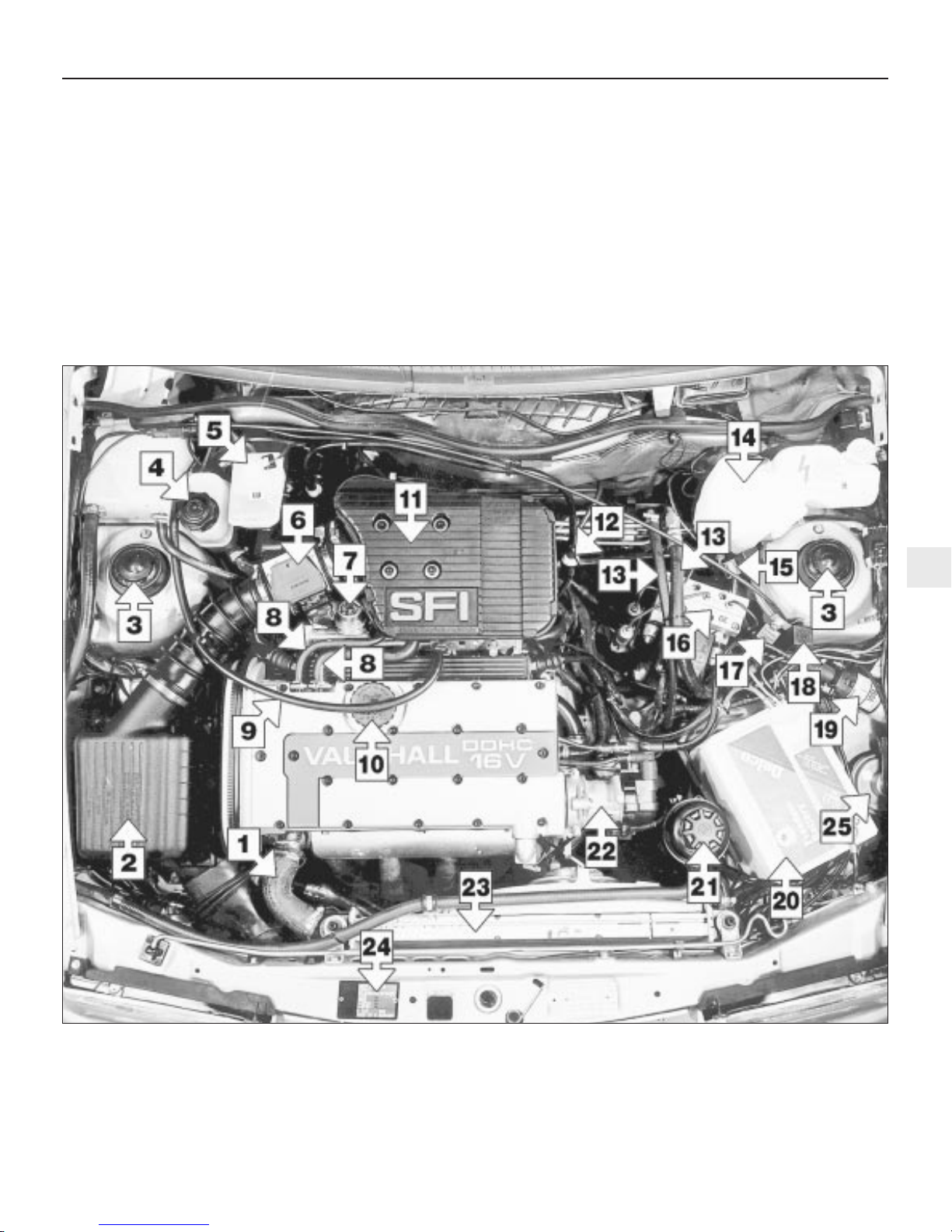

1Visually inspect the engine joint faces,

gaskets and seals for any signs of water or oil

leaks. Pay particular attention to the areas

around the camshaft cover, cylinder head, oil

filter and sump joint faces. Bear in mind that,

over a period of time, some very slight

seepage from these areas is to be expected;

what you are really looking for is any

indication of a serious leak. Should a leak be

found, renew the offending gasket or oil seal

by referring to the appropriate Chapters in this

manual.

2Also check the security and condition of all

the engine-related pipes and hoses. Ensure

that all cable-ties or securing clips are in

place, and in good condition. Clips which are

broken or missing can lead to chafing of the

hoses pipes or wiring, which could cause

more serious problems in the future.

3Carefully check the radiator hoses and

heater hoses along their entire length. Renew

any hose which is cracked, swollen or

deteriorated. Cracks will show up better if the

hose is squeezed. Pay close attention to the

hose clips that secure the hoses to the

cooling system components. Hose clips can

pinch and puncture hoses, resulting in cooling

system leaks. If wire-type hose clips are used,

it may be a good idea to replace them with

screw-type clips.

4Inspect all the cooling system components

(hoses, joint faces etc.) for leaks. Where any

problems of this nature are found on system

components, renew the component or gasket

with reference to Chapter 3.

5Where applicable, inspect the automatic

transmission fluid cooler hoses for leaks or

deterioration.

6With the vehicle raised, inspect the petrol

tank and filler neck for punctures, cracks and

other damage. The connection between the

filler neck and tank is especially critical.

Sometimes, a rubber filler neck or connecting

hose will leak due to loose retaining clamps or

deteriorated rubber.

7Carefully check all rubber hoses and metal

fuel lines leading away from the petrol tank.

Check for loose connections, deteriorated

hoses, crimped lines and other damage. Pay

particular attention to the vent pipes and

hoses, which often loop up around the filler

neck and can become blocked or crimped.

Follow the lines to the front of the vehicle,

carefully inspecting them all the way. Renew

damaged sections as necessary.

8From within the engine compartment,

check the security of all fuel hose attachments

and pipe unions, and inspect the fuel hoses

and vacuum hoses for kinks, chafing and

deterioration.

9Where applicable, check the condition of

the power steering fluid hoses and pipes.

Alternator drivebelt

Checking and adjustment

1Correct tensioning of the auxiliary drivebelt

will ensure that it has a long life. Beware,

however, of overtightening, as this can cause

excessive wear in the alternator.

2The belt should be inspected along its

entire length, and if it is found to be worn,

frayed or cracked, it should be renewed as a

precaution against breakage in service. It is

advisable to carry a spare drivebelt of the

correct type in the vehicle at all times.

3Although special tools are available for

measuring the belt tension, a good

approximation can be achieved if the belt is

tensioned so that there is approximately 13 mm

of free movement under firm thumb pressure at

the mid-point of the longest run between

pulleys. If in doubt, err on the slack side, as an

excessively-tight belt may cause damage to

the alternator or other components.

4If adjustment is required, loosen the

alternator upper mounting nut and bolt - use

two spanners, one to counterhold the bolt.

Lever the alternator away from the engine

using a wooden lever at the mounting bracket

until the correct tension is achieved, then

tighten the bolt securing the adjuster bracket,

and the alternator mounting nuts and bolts.

On no account lever at the free end of the

alternator, as serious internal damage could

be caused to the alternator.

Removal, renewal and refitting

5To remove the belt, simply loosen the

mounting nuts and bolts, and the bolt

securing the adjuster bracket, as described

previously, and slacken the belt sufficiently to

slip it from the pulleys. On models with power

steering it will first be necessary to remove the

power steering pump drivebelt as described

below.

6Refit the belt, and tension it as described

previously. Note that when a new belt has

been fitted it will probably stretch slightly to

start with and the tension should be

rechecked, and if necessary adjusted, after

about 5 minutes running.

Power steering pump drivebelt

Checking and adjustment

7Refer to the information given in paragraphs 1

to 3, noting that there should be

approximately 8 mm of free movement in the

belt.

8If adjustment is required, slacken the

adjuster bolt locknut (situated on the base of

the pump) and rotate the adjuster nut as

necessary to tension the belt. Once the belt

tension is correct, securely tighten the

locknut.

Removal, renewal and refitting

9To remove the belt, simply loosen the

locknut and fully slacken the adjuster nut

sufficiently to slip the drivebelt from the

pulleys.

10 Refit the belt, and tension it as described

previously. Note that when a new belt has

been fitted it will probably stretch slightly to

start with and the tension should be

rechecked, and if necessary adjusted, after

about 5 minutes running.

Alternator/power steering pump

drivebelt - later 1.6 litre models

Checking and adjustment

11 From March 1987 onwards, a single

drivebelt is used for the alternator and power

steering pump on 1.6 litre engines. The

drivebelt is of the ribbed type and runs at a

higher tension than the previous (V) belt.

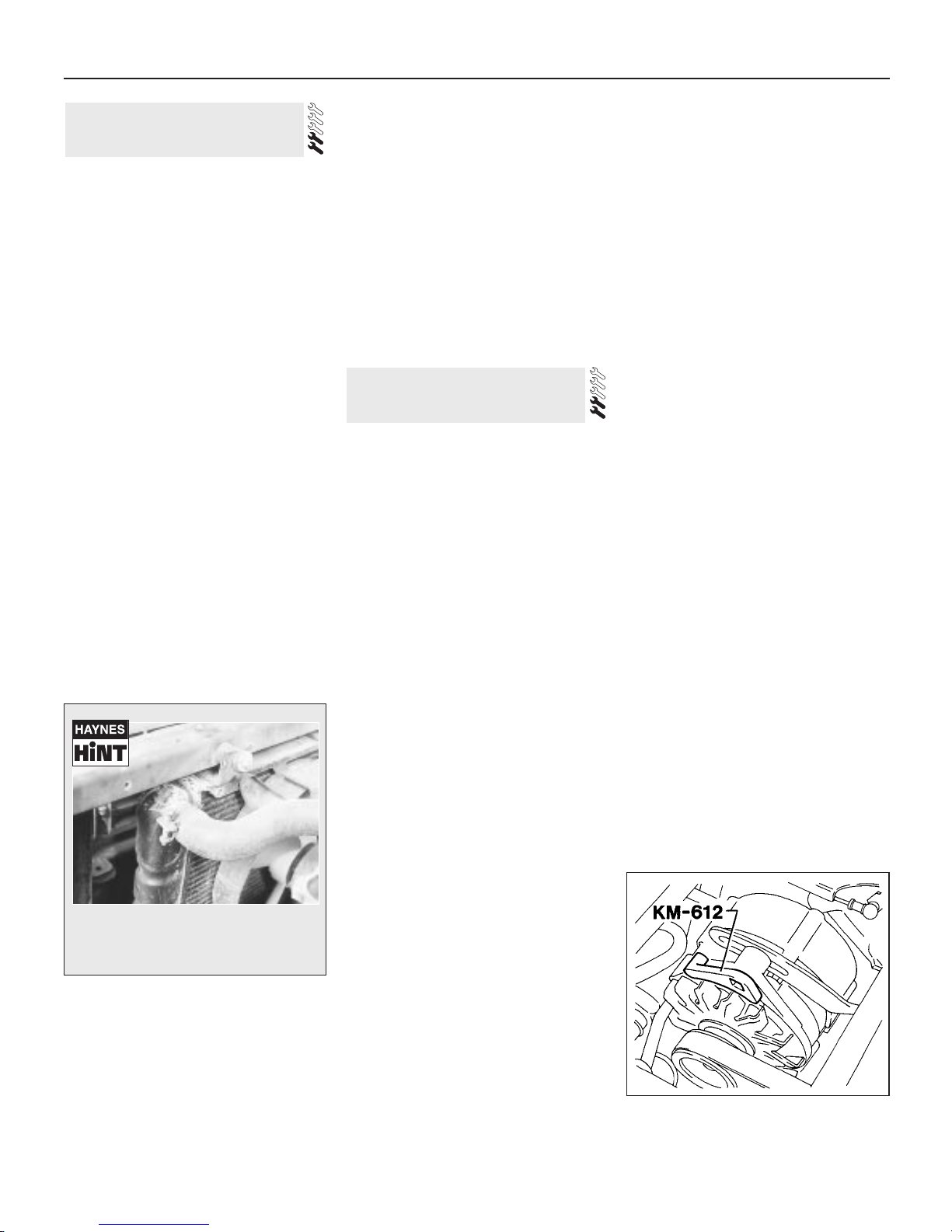

12 To set the tension accurately, make up or

obtain an adapter as shown (see illustration).

13 Slacken the alternator pivot and adjusting

strap bolts and fit the adapter. Using a torque

wrench apply a load of 55 Nm (40 lbf ft) for a

new belt, or 50 Nm (37 lbf ft) for an old belt.

Keep the tension applied and securely tighten

the alternator bolts.

Removal, renewal and refitting

14 To remove the belt, simply loosen the

alternator pivot and strap bolts and slip the

drivebelt from the pulleys.

9 Auxiliary drivebelt check and

renewal

8 Hose and fluid leak check

1•10 Every 9000 miles

9.12 Adapter KM-612 used for setting

drivebelt tension on later 1.6 litre models

A leak in the cooling system will usually

show up as white- or rust-coloured

deposits on the area adjoining the leak.