1

Chapter I – Undercarriage

Your Open Range recreational vehicle is designed to be as

maintenance free as possible. However, all moveable vehicles require

some care to reduce the possibility of unwanted breakdowns during

travel. Maintenance of your RV may not seem necessary at the time of

purchase, yet it is very important to keep your coach in it’s best condition

for your enjoyment. Normal maintenance is required to maintain warranty

coverage, reduce wear, and prolong the life of your coach.

1. FRAME

The steel frame on your Open Range recreational vehicle is cleaned

with a high pressure phosphate spray wash that removes oils, dirt, and

residue. After cleaning the frame is placed in an oven at 200°F, high

quality, water borne paint is then applied. A nal curing process is then

applied to produce a quality paint application.

No matter what quality or type of paint process is used, we must

remember that during travel the frame is exposed to stones, sand, road

debris, and any other objects found on the road. These items will cause

scratching and chipping of the paint inviting rust to begin from moisture.

Your frame needs to be inspected and examined every year to touch up

or repaint as normal maintenance. We suggest this be performed each

fall before storage to guard against winter moisture.

The paint to use is a gloss black, ozone safe exterior paint with no

uorocarbon, in a spray can.

You may wish to purchase a commercial rust proof undercoating

treatment, such as, Ziebart®, etc. However, even such higher priced

treatments are subject to road debris and damage.

2. COUPLER (Travel Trailers)

For the ball on your hitch use a light amount of chassis grease.

Lubricate the coupler’s pivot points with silicone spray. Avoid grease

or oil as they will draw dirt, potentially

damaging the coupler.

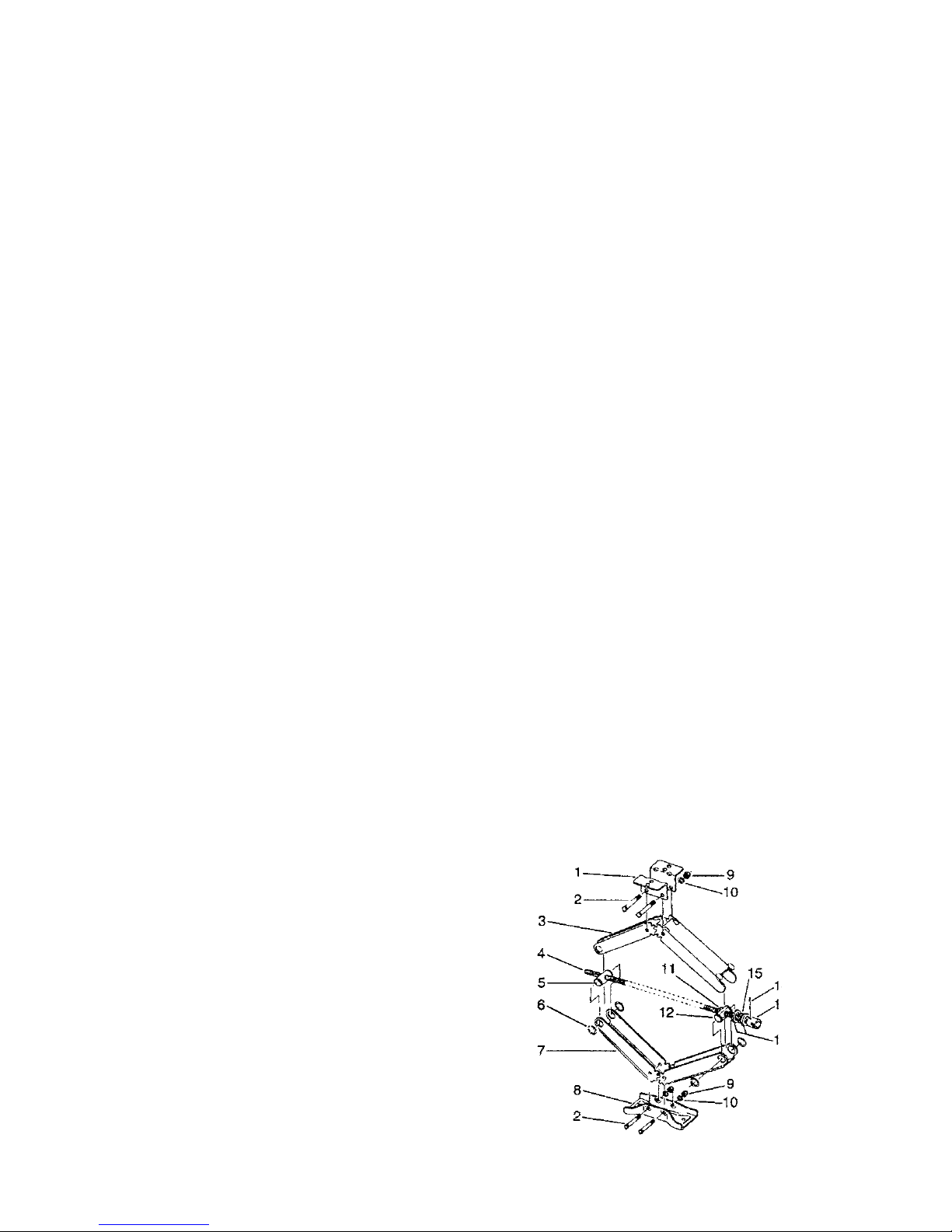

3. STABILIZER JACKS

On item #4 (illustration), drive screw,

spray silicone is recommended to be

applied two or more times per year. DO

NOT use oil or grease as it will attract dirt

and grit causing gradual deterioration.

Should jacks become rusty you may

wish to paint them; to stay more attractive