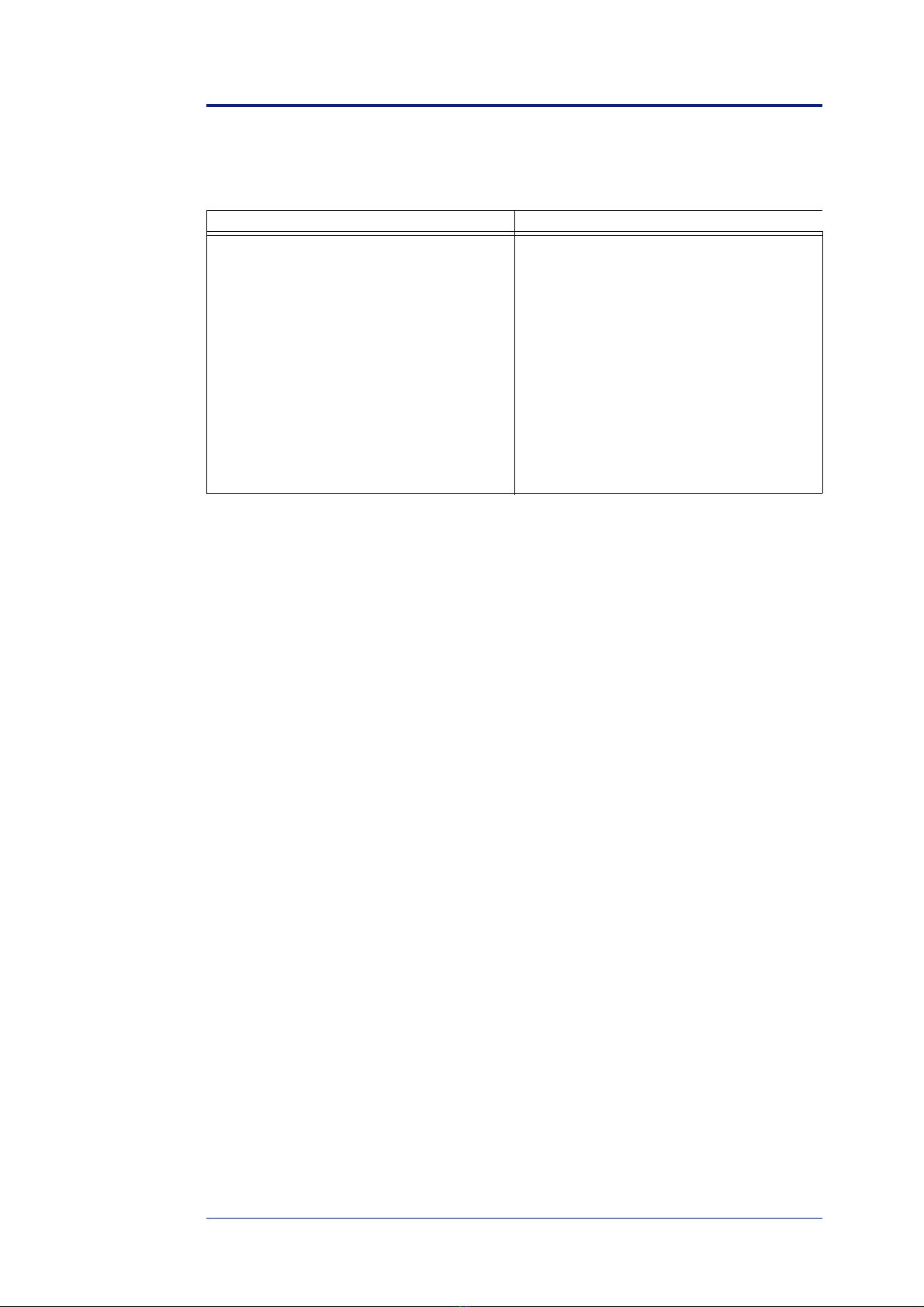

Contents

1 Emitters and receivers ................................................................................. 1

1.1 The ER060L system ...................................................................................... 1

1.1.1 Technical specifications ................................................................................. 1

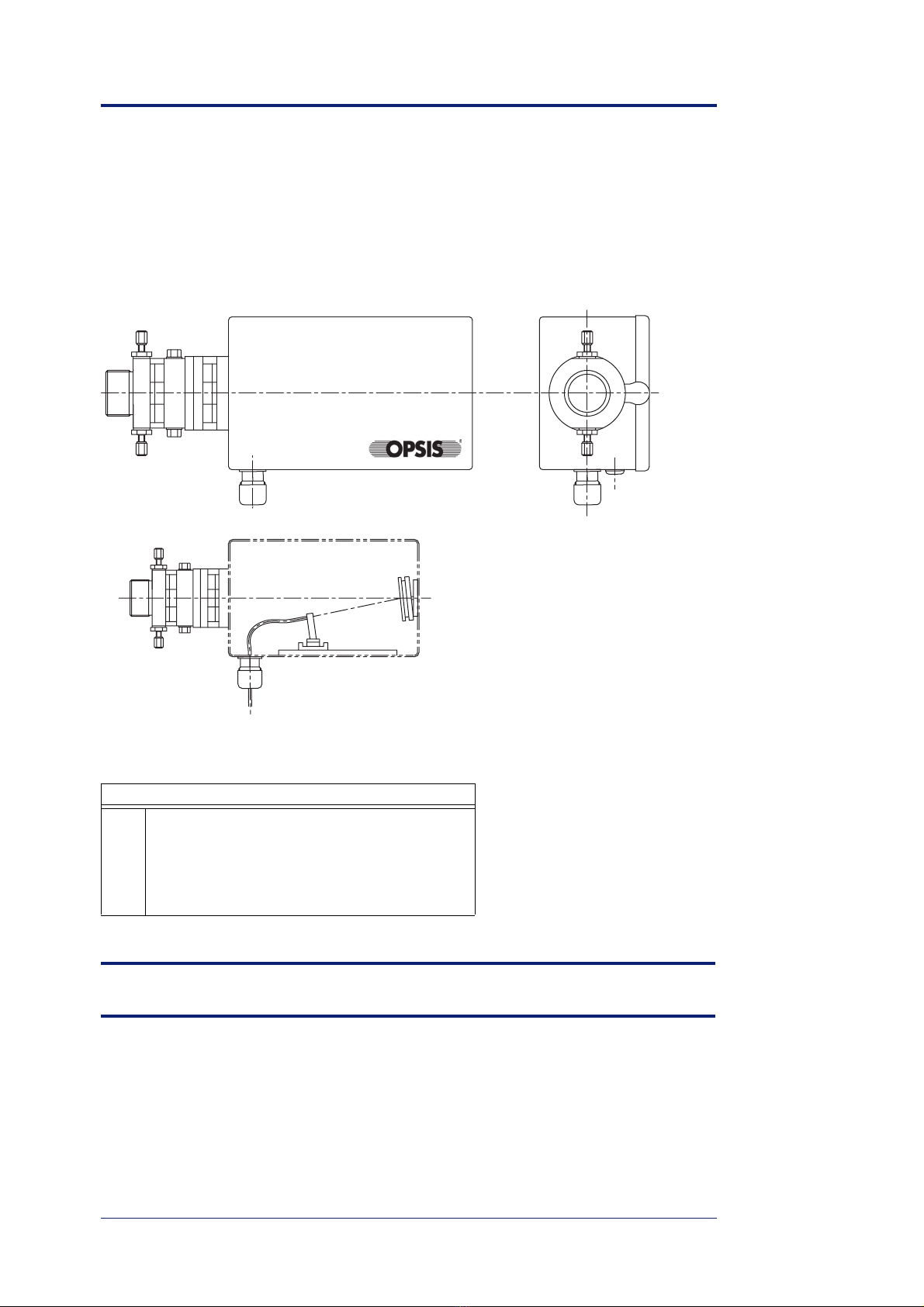

1.1.2 The emitter EM060L ..................................................................................... 2

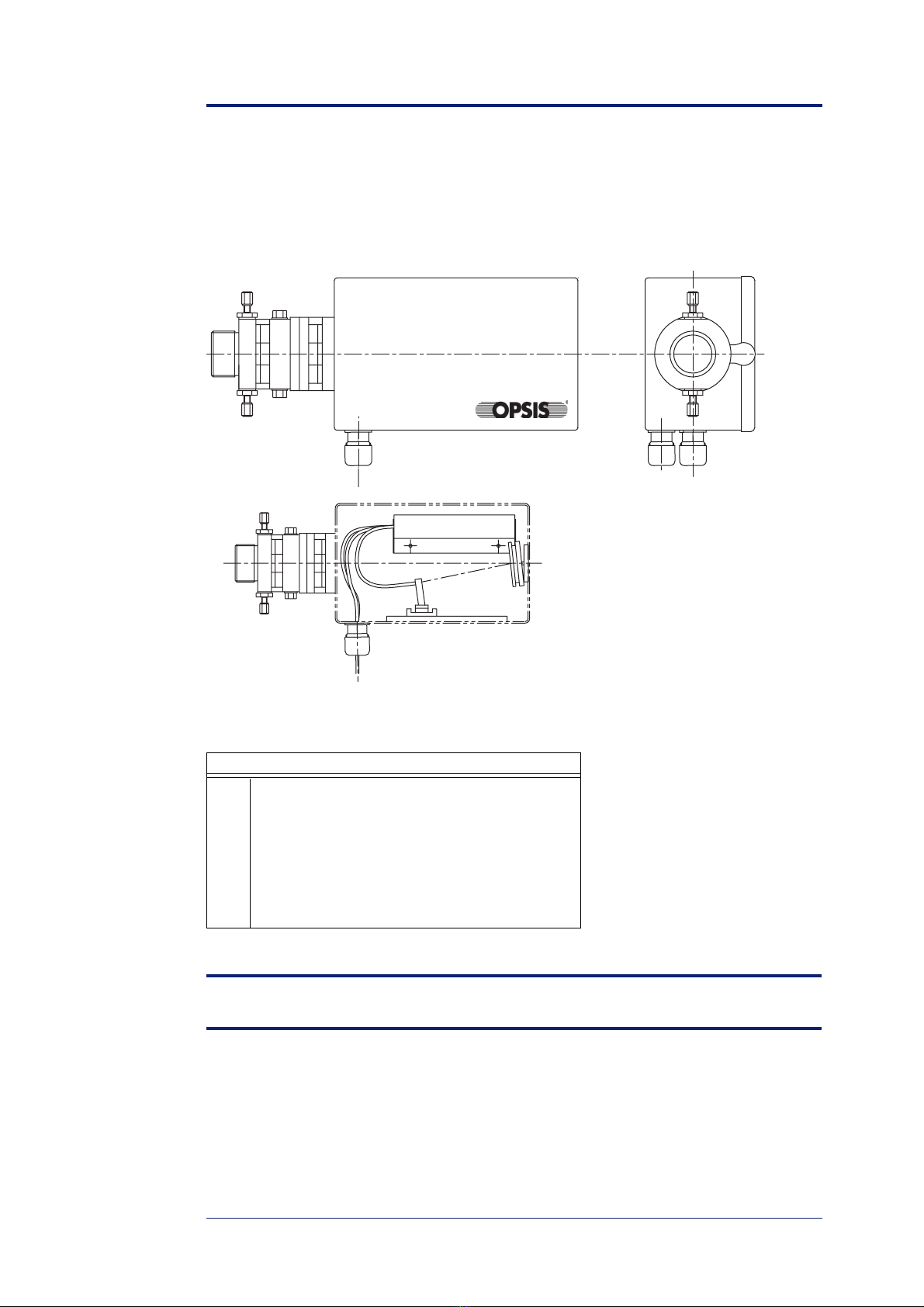

1.1.3 The receiver RE060L ..................................................................................... 3

1.2 The ER060AUTOL system ........................................................................... 4

1.2.1 Technical specifications ................................................................................. 5

1.2.2 The receiver RE060AUTOL .......................................................................... 5

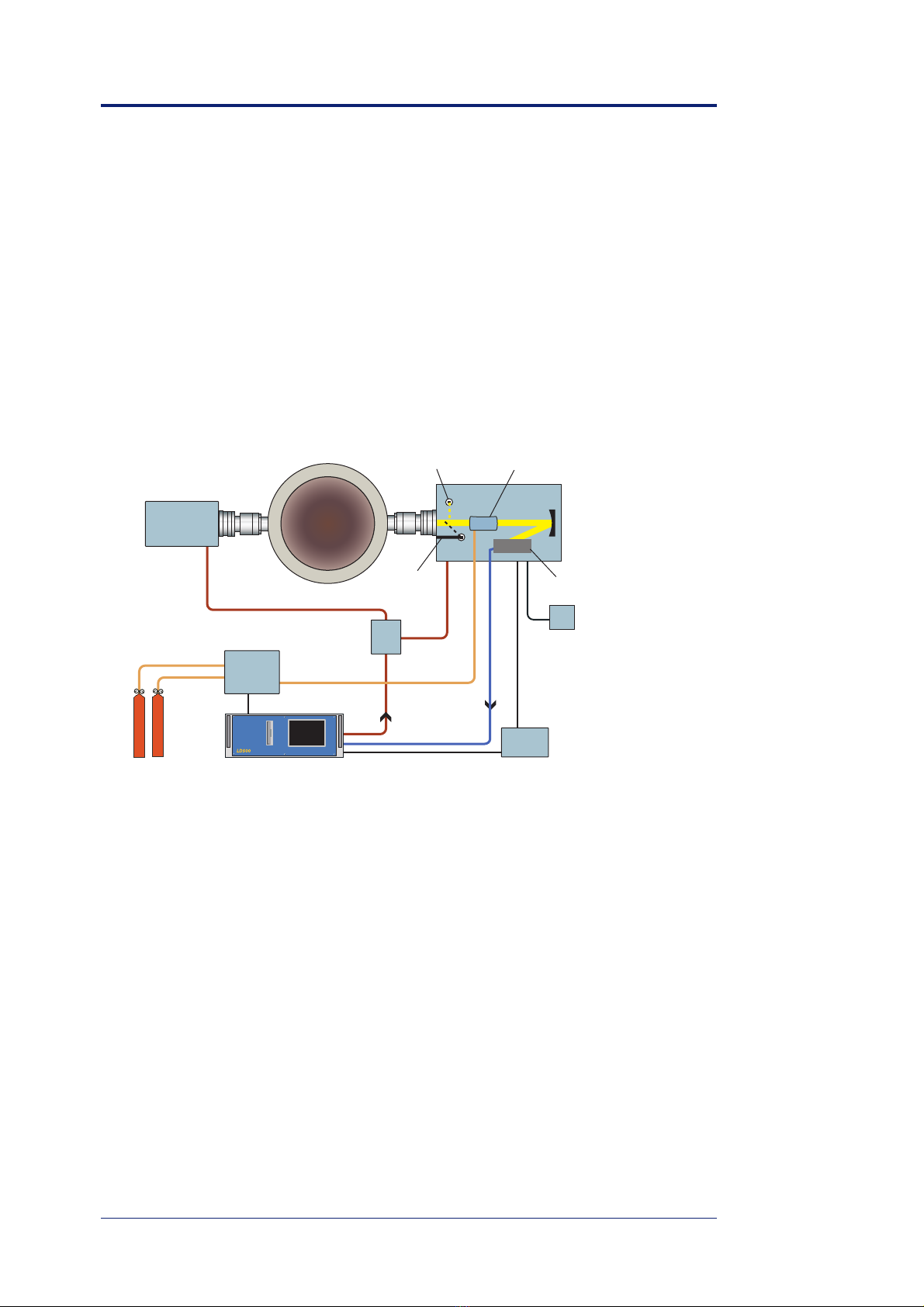

1.2.3 The calibration cell ........................................................................................ 5

1.3 Stack port connections - port installation kit ................................................. 6

2 LD500 CEM system accessories ................................................................. 7

2.1 The PM101L power supply ........................................................................... 7

2.2 The PW061 purge air cassette ....................................................................... 7

2.3 The optical fibres ........................................................................................... 8

3 CU004/007 Calibration unit ...................................................................... 11

3.1 Specifications ............................................................................................... 13

3.2 The control unit ............................................................................................ 13

3.3 Cables .......................................................................................................... 14

4 Safety precautions ...................................................................................... 17

4.1 Precautionary measures ............................................................................... 17

4.2 CU004/CU007 ............................................................................................. 18

5 Installation .................................................................................................. 19

5.1 Placement conditions for the emitter/receiver ............................................. 19

5.2 Placement conditions for the analyser ......................................................... 20

5.3 Flanges and PW061 cassettes ...................................................................... 20

5.4 Installation of ER060L ................................................................................ 21

5.5 Installation of ER060AUTOL ..................................................................... 21

5.5.1 Electrical connections .................................................................................. 22

5.5.2 Fiber optic connections ................................................................................ 22

6 Light adjustment kit LA060 ..................................................................... 23

6.1 Visually alignment of the transmitter and receiver with the LA060 ........... 24

6.2 Alignment of the transmitter and receiver with the LA060 with feedback

from the LD500 ........................................................................................... 24

6.3 Measure light throughput to ensure status of fibre or light transmitter

(version 1.2 and up) ..................................................................................... 25

6.4 Spare parts ................................................................................................... 25

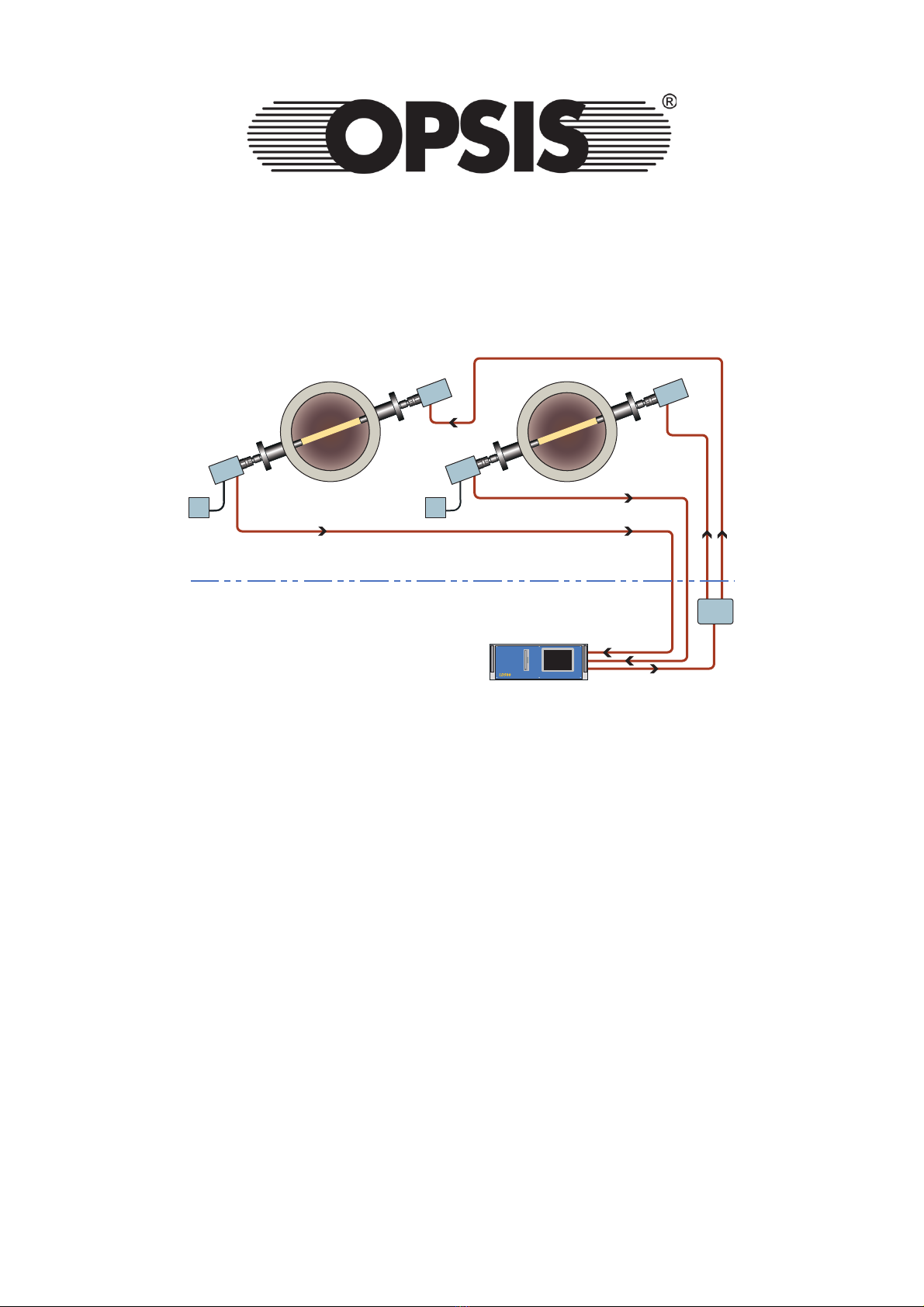

7 Multiplexers and demultiplexers .............................................................. 27

7.1 Splitting multiplexers and demultiplexers ................................................... 27

7.1.1 Splitting multiplexers, MX10nL .................................................................. 28