ERIKS ECON HCG 8370 User manual

Rev.1 Page 1 of 16

ECON HCG 8370

Self-powered Automatic

Contents Gauges

USER MANUAL

YARD :

HULL NUMBER :

IMO NUMBER :

YEAR :

ERIKS REF. :

CLASSIFICATION :

SHIPSNAME :

TYPE OF SHIP :

OWNER :

Rev.1 Page 2 of 16

CONTENTS

SECTION 1

1.1 Introduction

1.2 Description & Operation

1.3 Filling & Emptying the Tank

SECTION 2

2.1 Installation

2.2 Installing the transmitter

2.2.1 Installing the transmitter (external type)

2.2.2 Installing the transmitter (internal type)

2.3 Installing the capillary

2.4 Installing the indicator

SECTION 3

3.1 Specification

SECTION 4

4.1 Maintenance

4.1.1) Cleaning indicator face

4.1.2) Cleaning transmitter

4.1.2.1) External type transmitter

4.1.2.2) Internal type transmitter

SECTION 5

5.1 Malfunction & Remedy

Rev.1 Page 3 of 16

SECTION 6

6 Transport, packaging and storage

6.1 Transport

6.2 Packaging

6.3 Storage

SECTION 7

7.1 Ordering information

7.2 Available types and installation:

ERIKS bv reserves the right at any time and without notice to make specification changes, in

order to improve product design and performance, and as a consequence to revise manual

contents where necessary.

The information contained within this manual has been prepared with the cognisance of the

Health and Safety at Work, and is intended for use by trained personal conversant with this type

of equipment and normal engineering and safety practices.

Any application information included herein is intended for general guidance only. It is possible

to meet specific requirements of every application within the scope of this document.

IMPORTANT:

The instructions in this manual must be strictly followed.

The manufacturer declines all responsibility for any direct or indirect damage to property or

persons as well as for the consequence, for example, of lost production resulting from failure to

observe the instructions in this manual.

Rev.1 Page 4 of 16

SECTION 1

1.1 Introduction:

The HCG 8370 Series Hydrostatic tank Contents Gauge, ECON figure 8370, has long been

considered as one of the most reliable forms of tank gauging equipment available. The

instrument will indicate continuously the liquid contents of any shape of storage tank, and

display the data at considerable distance from the tank. The HCG 8370 Series can be supplied

with either an internal or external tank mounting transmitter plus a comprehensive range of

bulkhead plates or fittings, which allow the passage of capillary through oil and watertight

compartments in marine applications. In addition a special isolating maintenance valve assembly

is available for external transmitters.

Indicators have been designed to provide clear, easy to read data in one size, 160 mm diameter.

Dials are graduated in units to meet user’s requirements and are often marked with redial lines

to denote critical levels at various specific gravity’s.

The power required to operate the HCG 8370 Series hydrostatic tank contents gauge is derived

from the pressure exerted by the head of liquid within the tank (hydrostatic pressure). This

pressure is sensed by a stainless steel diaphragm set into the face of the transmitter and

conveyed by a length of capillary to a diaphragm within the indicator.

Deflection of the diaphragm within the indicator actuates a precision mechanism, which rotates a

pointer over a calibrated scale. The transmitting diaphragm, capillary and indicator diaphragm

together form a sealed system, prior to being charged with oxygen, is thoroughly examined for

leaks.

Not attempt should be made to disconnect the capillary from the instrument, except for mounting

if necessary.

1.2 Description & Operation

A flexible metallic diaphragm contained in the transmitter is so arranged that its internal volume

is connected, by capillary tubing, to a diaphragm within the indicator. The total volume contained

by these two diaphragms and the capillary tubing is charged with an gas and sealed. When the

transmitter is connected or installed in the tank the transmitting diaphragm is exposed to the

pressure exerted by the head of liquid above the transmitter‘s datum. This pressure adjusts the

position of the diaphragm and causes an equal pressure to be imparted to the gas within the

system, such pressure being conveyed by the capillary tubing to the indicator. With the increase

in pressure this diaphragm distends and causes a precision mechanism to rotate the pointer

over the calibrated scale.

1.3 Filling & Emptying the Tank:

The following points should be borne in mind when filling and emptying the tank.

1. The tank must be kept fully vented to atmosphere.

2. Overload must be kept within the limits stated when the instrument was ordered.

3 The temperature of the liquid must not be widely divergent from that specified.

(The gauge is fully compensated for all normal ambient temperature changes)

Rev.1 Page 5 of 16

SECTION 2

2.1 Installation:

WARNING:

Incorrect use of the gauge system can cause damage and injuries. Under this Directive, the user

ensures that the gauge system is installed and used in such way that hazards are eliminated to

a maximum extent.

Safety instructions:

The appropriate national safety regulations must be observed when mounting and operating

these gauge systems. Serious injuries and or damage can occur should the appropriate

regulations not be observed. Only appropriately qualified persons should work on these

instruments.

To insure long trouble-free service, considerable care must be exercised during installation to

avoid damage to the capillary tubing. Whenever possible, installation should commence by fixing

Rev.1 Page 6 of 16

the indicator in position, so that where is less risk of the instrument being damaged when the

capillary in unrolled. With the internal transmitter it may practical to disconnect the capillary

tubing from the indicator or the bulkhead fitting.

In such a case the disconnected coupling of the capillary should be adequately protected from

mechanical damage when routing the capillary. The capillary should be carefully unrolled along

the route to be followed. Do not pull the coil apart and attempt to correct the spring-like effect by

pulling with either the indicator or transmitter.

The following points should be noted:

1) Protect the transmitter against the ingress of foreign matter. Sharp particles of grit or dust can

puncture the diaphragm.

2) Use a correctly sized spanner to tighten connections.

3) Never twist the indicator or transmitter to tighten connections.

4) DO NOT drag the indicator, capillary and / or transmitter over sharp edges

5) DO NOT swing the indicator and / or transmitter by the capillary.

Transmitters from DN100 and bigger are provided with a special lifting handle on the transmitter.

The level of the indicator head in relation to the transmitter unit in no way affects the reading of

the gauge.

The following points should be checked against the original questionnaire or instructions sent to

us when ordering:

1) Is the liquid the same specific gravity as that given to us at the time of ordering?

Have the original dimensions been altered?

2) Has the position of the transmitter in relation to the tank bottom been altered?

3) Has the operating temperature been altered?

2.2) Installing of the transmitter

Different possibilities of installation are possible, depending of the tank type, available space etc.

There are two ways of installation:

- Side mounting on the tank wall, flanged or screwed.

- Inside the tank (submersed), vertical or horizontal with a mounting bracket.

2.2.1 Installing the transmitter (external type)

The HCG 8370 transmitter is bolted to a previously prepared steel flange (customer supply) on

the side of the tank, whose centre-line from the bottom of the tank must be in accordance with

the figures given by order.

Rev.1 Page 7 of 16

Care must be taken to ensure that the flange has a machined face, and that any weld does not

foul the transmitter.

The diaphragm detects the hydrostatic head of the tank contents through a full bored hole:

THE HOLE MUST BE DRILLED BEFORE FITTING THE TRANSMITTER.

The transmitter may be fitted using an isolating valve. This enables the transmitter to be

removed without draining the tank.

Take care tank is empty and not filled in the meantime if capillary will be connected after

fitting of the diaphragm.

2.2.2 Installing the transmitter (internal type)

The transmitter is mounted horizontally or vertical on an internal bracket with the diaphragm

facing downward at a pre-determined height from the tank bottom, which must be in accordance

with the figure given by order.

A connecting capillary protected by a stainless steel flexible tubing runs inside the tank to a

bulkhead flange or other bulkhead fitting on the side or top of the tank. The capillary passes

through the bulkhead flange or bulkhead fitting. Stainless steel protected capillary is used

between this bulkhead flange or bulkhead fitting and the indicator. All capillary must be

adequately supported particularly inside the tank.

Take care tank is empty and not filled in the meantime, if capillary will be connected after

fitting of the diaphragm and bulkhead flange or fitting.

Care should be taken to avoid physical impact of solid objects onto the transmitter face. Care

should be taken, particularly in the case of the submersible mounted transmitter when lowering

into the tank that solid objects resting on the bottom of the tank are not in direct contact with the

transmitter face, as this will cause large errors.

The transmitter should be installed well away from tank inlets, pumps and areas of turbulence or

pressure surges, as there can cause errors or even damage transmitter.

CAUTION:

- If any kind of work are carried out inside the tank it is necessary to protect the diaphragm of the

transmitter against chocks, sandblasting , painting, etc.

2.3 Installing the capillary

Gauges are supplied fitted with a specified length of SS armour covered capillary.

All capillary must be adequately supported.

Support the capillary (internal or external to the tank) in cable tray wherever possible and secure

at intervals of 300 mm with cleats.

Provide cleats at the beginning and completion of every band.

Rev.1 Page 8 of 16

Although the capillary stainless steel covering is of a robust quality, provide a shield where

mechanical damage is likely to occur.

Capillary bends should not have a radius of less than 5 cm.

Avoid routing the capillary where it could be used as a “pipe on which to hang objects”.

Do check capillary armoured cover for signs of damage (cuts, weld spatter, burns etc.)

particularly inside the tank area. Damage to the armour cover can means damaged capillary.

This may affects the reading of the gauge.

DO NOT fix capillary alongside pipes with a temperature which exceed 50°C.

When connecting the capillary to the transmitter or indicator take care new seals are used.

A set of spare seals is tied to the coupling.

NOTE:

- During disassembly capillary, check that the system is no longer under pressure, tank empty or

no pressure on transmitter.

- During assembly capillary, check that the system is not under pressure, tank empty or no

pressure on transmitter.

2.4 Installing the indicator

The indicator must be mounted in compliance with standard practice.

The indicator is provided with a back plate for wall mounting.

The indicator must not be subjected to:

-Mechanical shocks

-Vibrations

-Temperatures greater or less than operating temperatures

SECTION 3

3.1 Specifications

3.1.1 Operational Data

Maximum Error

At reference conditions the maximum error will not exceed ± 1.6% of full scale deflection.

Operating Temperature

As standard : -20°C to +50°C (depending on liquid)

Ranges within : -50°C to +100°C to order

Overload

Normally 25% above maximum range but protection also given to 2 bar.

3.1.2. Construction Data

Transmitter

Standard transmitters comprise a stainless steel diaphragm, welded into a stainless steel plate,

size depending on type.

Rev.1 Page 9 of 16

Tank connection : Depending on type

Material flange : AISI316/1.4401

Material diaphragm : AISI316/1.4401

Capillary lengths

Maximum length 10 metre.

Longer is possible but will slow down the indication.

Capillary material : red copper with SS armoured cover

Material armoured cover : AISI304/1.4301

Indicators

Indicator size : Ø 160 mm

Indicator mounting : back flange for wall mounting

Material indicator housing : AISI304/1.4301

Protection class indicator : IP-45

Capillary connection indicator : Bottom side

Indicator scale division : m³ according tank volume table

Indication : By pointer, black, on white background with white figures

Material indicator window : Mineral glass 4 mm

SECTION 4

4.1 Maintenance

Providing that the instrument has been installed with care, it will give many years of trouble- free

service.

Maintenance operations are limited to periodical cleaning of the indicator face and ensuring that

the transmitter is kept clear of sludge or congealed liquid.

4.1.1) Cleaning indicator face

Maintenance task procedure (and safety procedures):

- Clean the indicator face with a soft cloth with a glass-cleaner or soapy water.

- Dry the indicator face with a soft cloth.

- Do not use a dirty or greasy cloth and/ or aggressive cleaner.

Average interval between maintenance task:

- Clean indicator face on regular times, ones a month, and when it is too dirty to do a right

reading.

Average time required to perform a task:

- Cleaning of the indicator face will takes max. 5 minutes.

Required spares, tools, maintenance resources:

- Required spares : NON

- Required tools : NON

- Maintenance resources : Glass cleaner, soft cloth.

4.1.2) Cleaning transmitter

Rev.1 Page 10 of 16

4.1.2.1) External type transmitter

When external type transmitter is employed on an installation viscous fuel, the transmitter should

be heavily logged and, if possible, fitted with an electrical tracer. Alternatively, the transmitter

should be positioned close to outflow heaters etc.

Where water is being measured and the tank is exposed to the weather, normal winter

precautions must be observed to prevent the transmitter being damaged by the formation of ice

around the diaphragm.

To cleanse the congealed fluid or sludge from a transmitter it must be removed from the tank so

obviously the tank must be drained first, unless there is an isolating valve fitted.

The following procedure should be adopted by cleaning:

a) Close isolating valve, if fitted, or empty tank.

b) Remove the transmitter from the tank by unscrewing the bolts or ¾” BSP union (depending on

type of connection).

As sludge deposits may be present in the isolating valve and / or transmitter connection, it is

advisable to place a container directly beneath the isolating valve and / or transmitter to catch

the small quantity of fluid which may drip from the isolating valve and / or transmitter.

c) Place the transmitter in a container of non-corrosive solvent compatible with liquid being

measured. For example, for fuel oils use paraffin.

ON NO ACCOUNT INSERT A PROBE INTO THE TRANSMITTER CONNECTION OR MAKE

ANY ATTEMPT TO DISMANTLE THE TRANSMITTER OR DISCONNECT THE CAPILLARY.

c) Gently agitate the transmitter in the solvent until the congealed liquid is seen to be leaving the

transmitter connection. To assist in dislodging stubborn deposits a small quantity of solvent may

be poured into the transmitter connection and, with the connection sealed for example by a

hand, the transmitter gently shaken.

Continue with cleaning operations until all sludge has been expelled.

Before re-connecting the transmitter to the tank lightly open de isolating valve to ensure that

heavy sludge has not accumulated around the valve and would prevent free flow of liquid into

the transmitter.

Should it appear that the tank contains an excessive quantity of sludge the assistance of the

local fuel distributor should be sought.

Average interval between maintenance task:

- Clean the transmitter in the tank at least every survey of the tank.

Average time required to perform a task:

- Cleaning of the transmitter will takes approx. 30 minutes.

Required spares, tools, maintenance resources:

- Required spares : NON

- Required tools : Spanner, size depending on type of tank connection

- Maintenance resources : Container

: No-corrosive solvent

Rev.1 Page 11 of 16

4.1.2.2) Internal type transmitter

When internal type transmitter is employed on an installation viscous fuel, the transmitter should

be heavily logged and, if possible, fitted with an electrical tracer. Alternatively, the transmitter

should be positioned close to outflow heaters etc.

Where water is being measured and the tank is exposed to the weather, normal winter

precautions must be observed to prevent the transmitter being damaged by the formation of ice

around the diaphragm.

To cleanse the congealed fluid or sludge from a transmitter it must be removed from the tank so

obviously the tank must be drained first, made gas free and cleaned for entering.

The following procedure should be adopted by cleaning:

a) Make tank empty.

b) Make tank gas free.

c) Clean the tank.

b) Remove the transmitter from its mounting bracket in the tank by unscrewing the two M16

bolts.

e) Place the transmitter in a container with non-corrosive solvent compatible with liquid being

measured. For example, for fuel oils use paraffin.

ON NO ACCOUNT INSERT A PROBE (SCREW DRIVER FOR EXAMPLE) INTO THE

TRANSMITTER OR MAKE ANY ATTEMPT TO DISMANTLE THE TRANSMITTER OR

DISCONNECT THE CAPILLARY.

f) Gently agitate the transmitter in the solvent until the congealed liquid is seen to be leaving the

transmitter. To assist in dislodging stubborn deposits a small quantity of solvent may be poured

into the transmitter, the transmitter gently shaken.

g) Continue with cleaning operations until all sludge has been expelled.

Should it appear that the tank contains an excessive quantity of sludge the assistance of the

local fuel distributor should be sought.

Average interval between maintenance task:

- Clean the transmitter in the tank at least every survey of the tank.

Average time required to perform a task:

- Cleaning of the transmitter will takes approx. 30 minutes.

- Complete operation, emptying tank, making gas free, cleaning of the tank and cleaning of

transmitter

will take approx. 2 days.

Required spares, tools, maintenance resources:

- Required spares : NON

- Required tools : Spanner M16

- Maintenance resources : Container

: No-corrosive solvent

Rev.1 Page 12 of 16

MAINTENANCE, VERIFICATION OR RE-CALIBRATION MUST BE CARRIED OUT BY

PERSONNEL APPROVED BY THE CONSTRUCTOR AND USING SUITABLE EQUIPMENT.

Whenever a service visit is required, please quote the tank name of the instrument.

SECTION 5

5.1 Malfunction and Remedy

INFORMATION:

Before you take any action by a misreading take care of the following:

- The adjustment of the gauge is calculated with the offset of the transmitter and the specific

gravity of the liquid.

Before comparing the level, check the offset of the transmitter and the specific gravity of the

liquid in the tank.

If it is different, you may have a significant error.

- The indication is without any Trim and / or List correction. This means if the manual sounding

pipe is not located close to the transmitter, you may have a significant difference between

manual sounding and read-out.

- For tanks with a shape, check if the manual sounding pipe is not bent or if the end of the pipe

is not installed above or below the transmitter position. If “yes”: you have to compare the volume

in according with the manual sounding tables.

5.1.1 Symptoms:

a) The gauge indicates a value above that which is known to be in the tank.

b) The gauge indicates a value below that which is known to be in the tank.

c) The pointer gradually returns to zero.

d) The pointer shows no movement with variation in the liquid level.

e) The pointer starts to make a second sweep of the scale.

f) Indication is erratic and unstable –varies with temperature.

5.1.2 Remedy:

a) 1. Check that tank dimensions (including slope and direction relative to gauge transmitter,

specific gravity and position of transmitter) are in accordance with information given to

ERIKS bv at the time of order.

Providing that dimensions are changed the instrument has to be modified.

Copies of the tank calculation to which the gauge was originally manufactured are

available.

On receipt of the calculations they should be compared with the makers calculations. If

the figures agree and a constant error is evident, it is possible to reset the pointer to the

correct figure. A reset should be made as near as possible to half-scale deflection.

Further check readings should be taken at other points on the scale. If the instrument is

not within the accuracy guaranteed by ERIKS bv then it should be returned

to ERIKS bv for attention.

Rev.1 Page 13 of 16

2. Check that the gauge transmitter is not choked with congealed liquid or sludge.

Clean transmitter.

3. Check that the tank’s ventilation is not blocked. If a gauge shows a normal reading when

the manhole cover is released, the vent pipe should receive attention.

4 Check that the pointer is not touching the dial or indicator face.

b) 1. Check as in a) 1. Above.

2. Check that the capillary tubing has not been damaged or fractured. Should the capillary

be damaged in any way, the instrument must be returned to our Works. Our service

engineers cannot rectify such damage on site.

3. Check as in a) 2. Above.

4. Check that the gauge has not been calibrated from a datum other than tank bottom.

Your dipstick will almost certainly be calibrated from the bottom of the tank. Dials

commencing at zero will invariable from the centre line of the transmitter or feed line

from the tank, ignoring falling below this level.

5. Check that the transmitter has been connected to the feed pipe from the tank and is

being subjected to loss in pressure due to flow of liquid or the effects of suction pumps

that may be in the circuit.

c) 1. Check as in b) 2.

2. Return gauge to our Service Department or ask for the assistance of one of our

engineers.

3. Check as in b) 5..

d) 1. Check as in a) 2.

2. Check as in a) 4.

3. Return gauge to our Service Department or ask for the assistance of one of our

engineers.

e) 1. Check as in a) 1.

2. Check as in a) 3

f) 1. Check as in a) 2.

2. Return gauge to our Service Department or ask for the assistance of one of our

Service Engineers.

NOTE:

- During disassembly capillary, check that the system is no longer under pressure, tank empty or

no pressure on transmitter.

- During assembly capillary, check that the system is not under pressure, tank empty or no

pressure on transmitter.

Rev.1 Page 14 of 16

- Use by assembly of capillary new seals, spare seals are tied to the couplings.

SECTION 6

6). Transport, packaging and storage

6.1) Transport

Check the instrument for any damage that may have been caused by transport.

Obvious damage must be reported immediately.

Damage through improper transport;

- With improper transport, a high level of damage to property can occur. When unloading packed

goods upon delivery as well as during internal transport, proceed carefully and observe the

symbols on the packaging.

With internal transport, observe the instructions in chapter 1.2 “Packaging and storage”.

6.2) Packaging

Do not remove packaging until just before mounting. Keep the packaging, especially the

diaphragm protection (if available).

This will provide optimum protection during transport (e.g. cleaning, change in installation site,

sending for repair).

- With improper unpacking, a high level of damage to property can occur.

- Damage to the diaphragm during unpacking. Avoid touching the diaphragm after removing the

diaphragm protection. Impermissible mechanical loading (e.g. pressing the diaphragm) can

result in measuring deviations or even in the complete failure of the measuring instrument.

- To protect the pressure gauges from mechanical damage keep them in the original packaging

until installation.

6.3) Storage

Permissible conditions at the place of storage:

- Storage temperature: -40 ... +70 °C

Avoid the following influence:

- Not in the open air

- Not exposed to corrosive media

- Mechanical vibration shock (putting it down hard)

- Protect the instrument from humidity and dust.

Rev.1 Page 15 of 16

SECTION 7

7.1 Ordering information:

If you want to other new instruments (only supply of complete instruments is possible) please

mention the following information on your order:

-Vessels name

-IMO number

-New building number vessel

-Ships owner

-Yard vessel built of

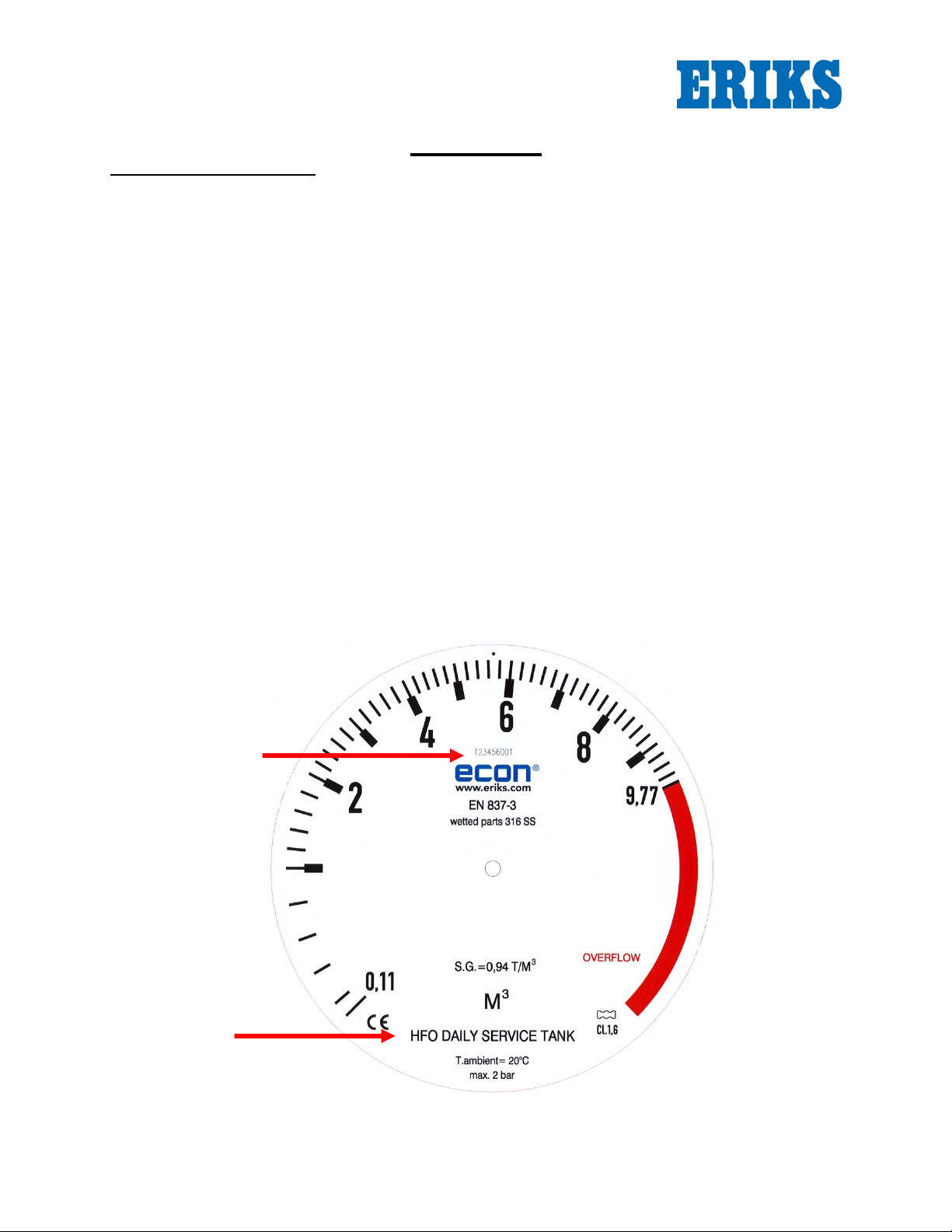

-Serial number of the old instrument, to be find on indicator scale plate above ECON logo

-Tank name mentioned on scale plate.

If that information cannot be found or is unreadable you can give the following information:

-Size of the transmitter flange, or type of transmitter

-Tank name

-Kind of liquid in the tanks

-S.G. of the liquid in the tanks

-Temperature of the liquid in the tanks

-Distance between diaphragm and tank bottom (offset)

-Length of the capillary between diaphragm and indicator

-A picture from the indicator and transmitter will give lot information.

Serial number

Tank name

Rev.1 Page 16 of 16

7.2 Available types and installation:

Table of contents