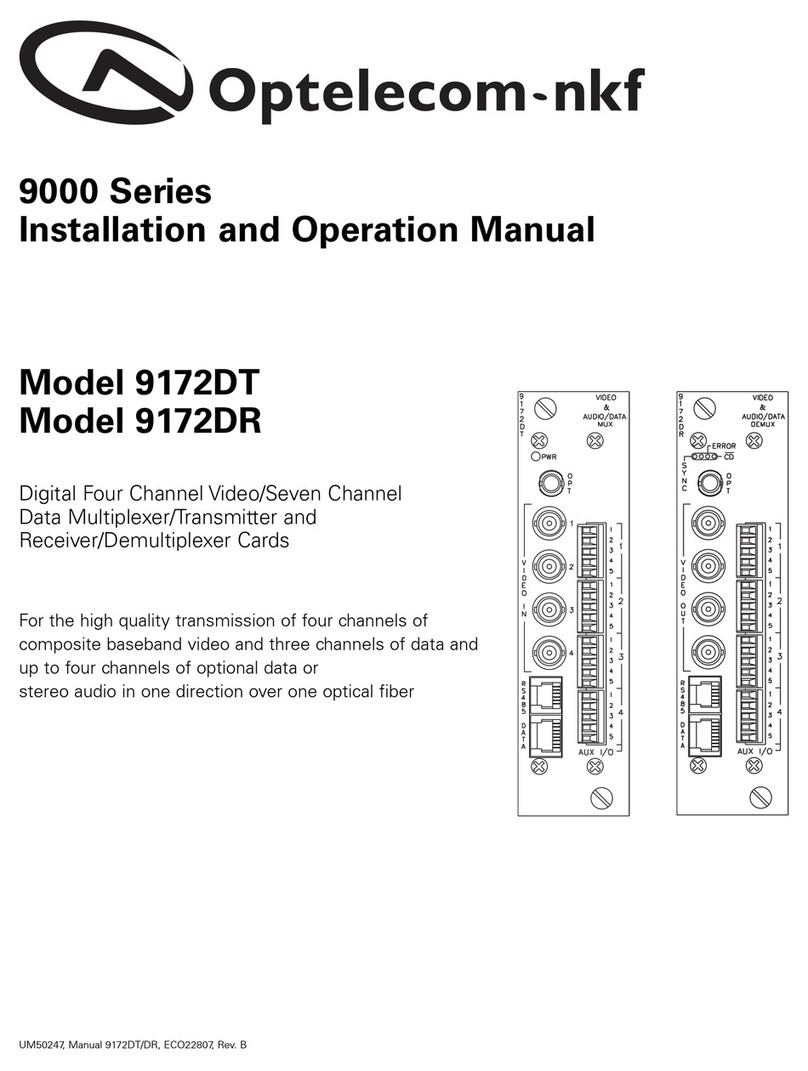

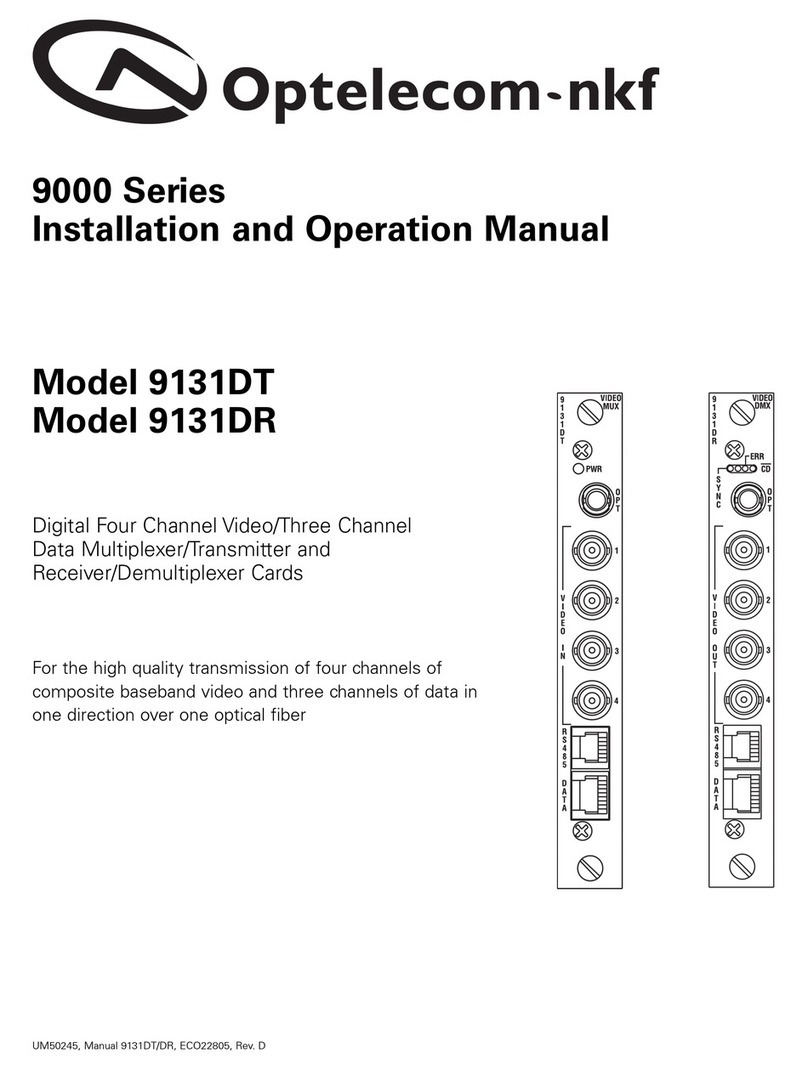

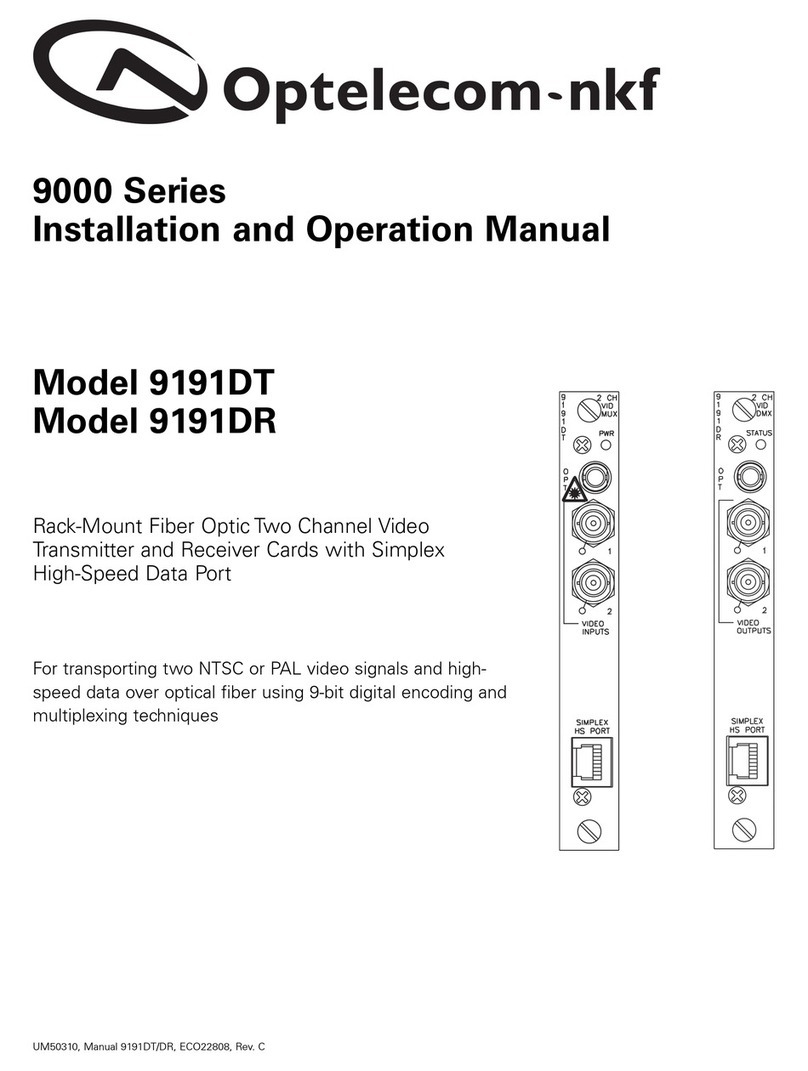

3

6. Safety, EMC, ESD

General

The safety information contained in this section, and on

other pages of this manual, must be observed whenever this

unit is operated, serviced, or repaired. Failure to comply with

any precaution, warning, or instruction noted in the manual

is in violation of the standards of design, manufacture, and

intended use of the unit.

Installation, adjustment, maintenance and repair of this

equipment are to be performed by trained personnel aware of

the hazards involved. For correct and safe use of the

equipment and in order to keep the equipment in a safe

condition, it is essential that both operating and servicing

personnel follow standard safety procedures in addition to the

safety precautions and warnings specified in this manual, and

that this unit be installed in locations accessible to trained

service personnel only.

Optelecom-NKF assumes no liability for the customer’s

failure to comply with any of these safety requirements.

UL/IEC/EN 60950-1: General safety requirements

The equipment described in this manual has been

designed and tested according to the UL/IEC/EN 60950-1

safety requirements.

If there is any doubt regarding the safety of the equipment, do

not put it into operation. This might be the case when the

equipment shows physical damage or is stressed beyond

tolerable limits (e.g. during storage and transportation).

Before opening the equipment, disconnect it from all power

sources. The equipment must be powered by a SELV*) power

supply.

When this unit is operated in extremely elevated temperature

conditions, it is possible for internal and external metal

surfaces to become extremely hot.

Optical safety

This optical equipment contains Class 1M lasers or LEDs

and has been designed and tested to meet IEC 60825-

1:1993+A1+A2 and IEC 60825-2:2004 safety class 1M

requirements.

Optical equipment presents potential hazards to testing and

servicing personnel owing to high levels of optical radiation.

When using magnifying optical instruments, avoid looking

directly into the output of an operating transmitter or into the

end of a fibre connected to an operating transmitter, or there

will be a risk of permanent eye damage.Precautions should

be taken to prevent exposure to optical radiation when the

unit is removed from its enclosure or when the fiber is

disconnected from the unit. The optical radiation is invisible

to the eye.

Use of controls or adjustments or procedures other than

those specified herein may result in hazardous radiation

exposure.

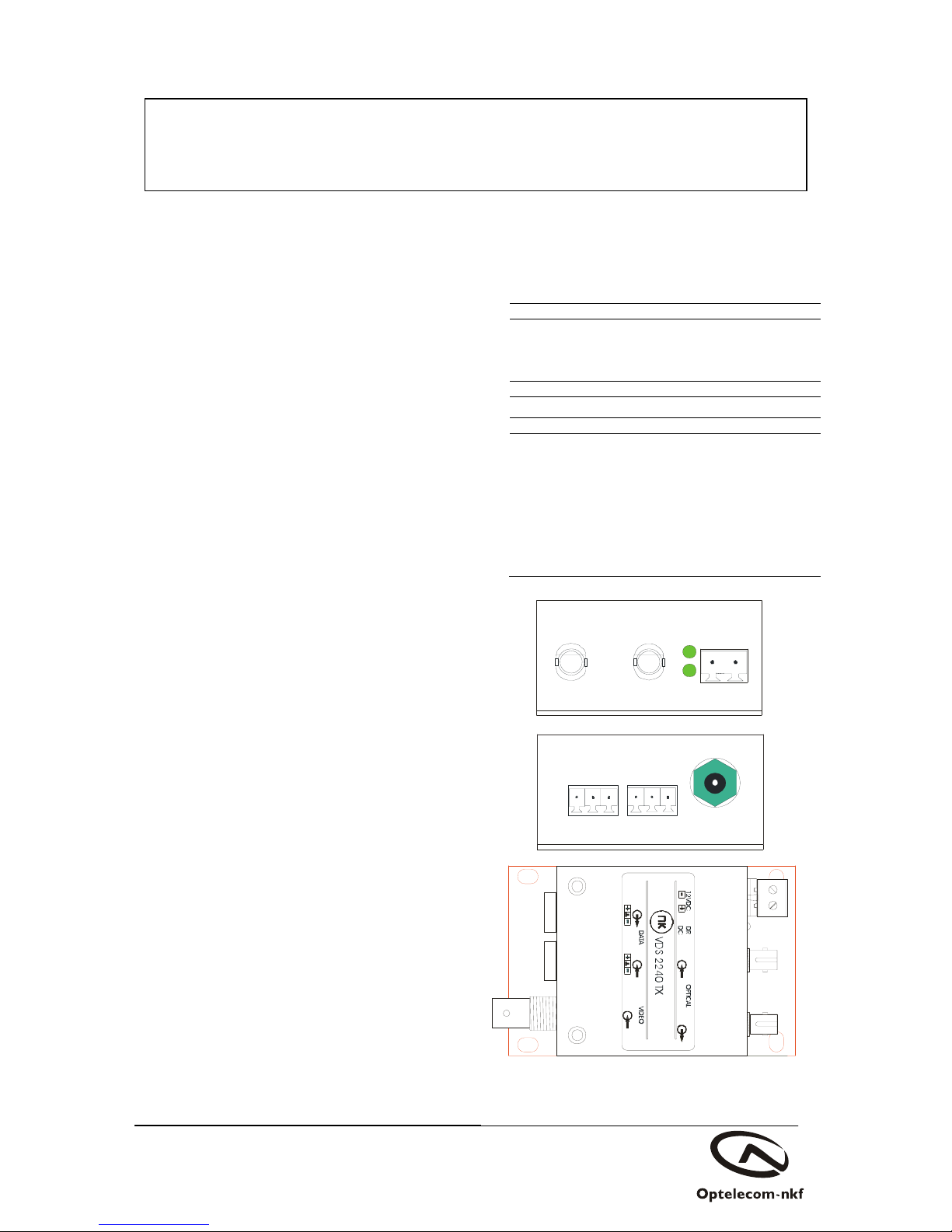

The installer is responsible for ensuring that the label

depicted below (background: yellow; border and text: black)

is present in the restricted locations where this equipment is

installed.

The locations of all optical connections are listed in the

Indications and Connectors section of this manual.

Optical outputs and wavelengths are listed in the Technical

Specifications section of this manual.

EMC

The equipment has been tested and found to meet the CE-

regulations relating to EMC, and complies with the limits

for a Class B device, pursuant to Part 15 of the FCC rules.

These limits are designed to provide reasonable protection

against interference to radio communications in any

installation. The equipment generates, uses and can radiate

radio frequency energy; improper use or special

circumstances may cause interference to other equipment or a

performance decrease due to interference radiated by other

equipment. In such cases, the user will have to take

appropriate measures to reduce such interactions between this

and other equipment.

Any interruption of the shielding inside or outside the

equipment could cause the equipment to be more prone to fail

EMC requirements.

Non-video signal lines must use appropriate shielded CAT5

cabling (S-FTP), or at least an equivalent.

If system components, such as cabling (e.g. coaxial cable,

data/audio/cc wiring) and/or the units, are used outdoors,

ensure that all electrically connected components are

carefully earthed and protected against surges (high voltage

transients caused by switching or lightning).

ESD

Electrostatic discharge (ESD) can damage or destroy

electronic components. Proper precautions should be

taken against ESD when opening the equipment.

*) SELV: conforming to IEC 60950-1, <60VDC output, output

voltage galvanically isolated from mains. All power supplies or

power supply cabinets available from Optelecom-NKF comply

with these SELV requirements.

7. Product disposal

Recycling

The unit contains valuable materials which qualify for

recycling. In the interest of protecting the

natural environment, properly recycling the

unit at the end of its service life is imperative.

Hazard Level 1M

©Optelecom-NKF 2008

Version 001205-4a

VDS TX (MW03SP3)