iv

Sicherheitsanleitungen RM-1

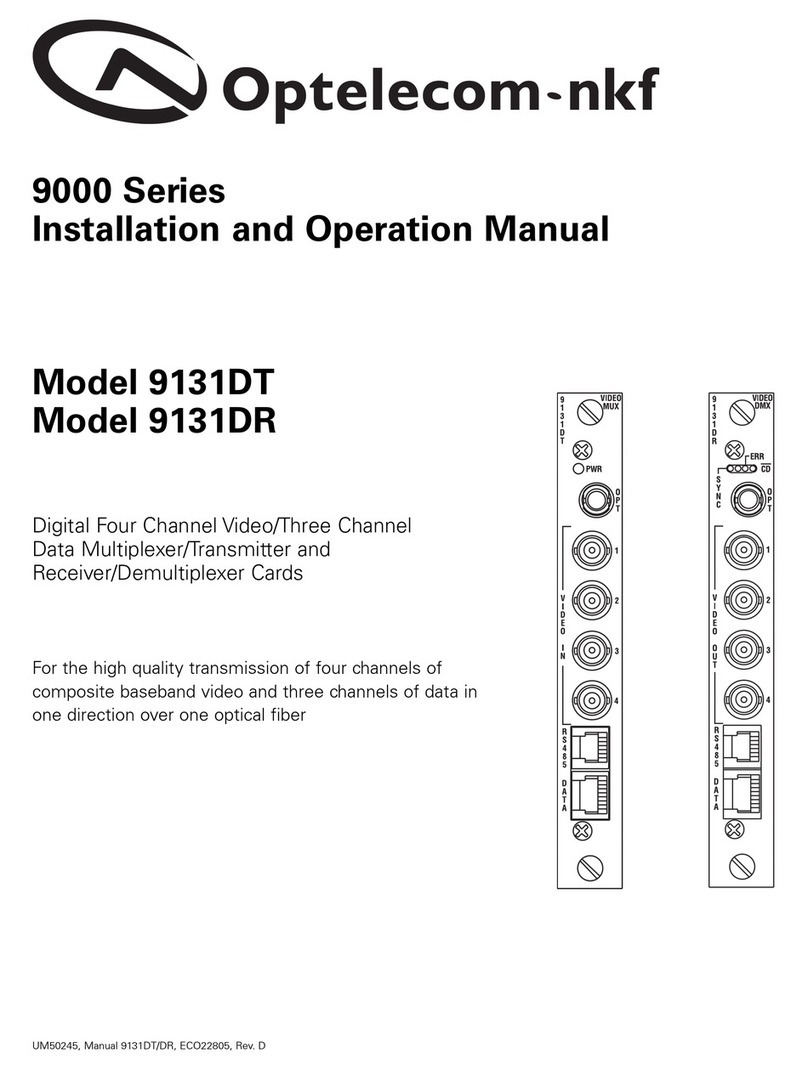

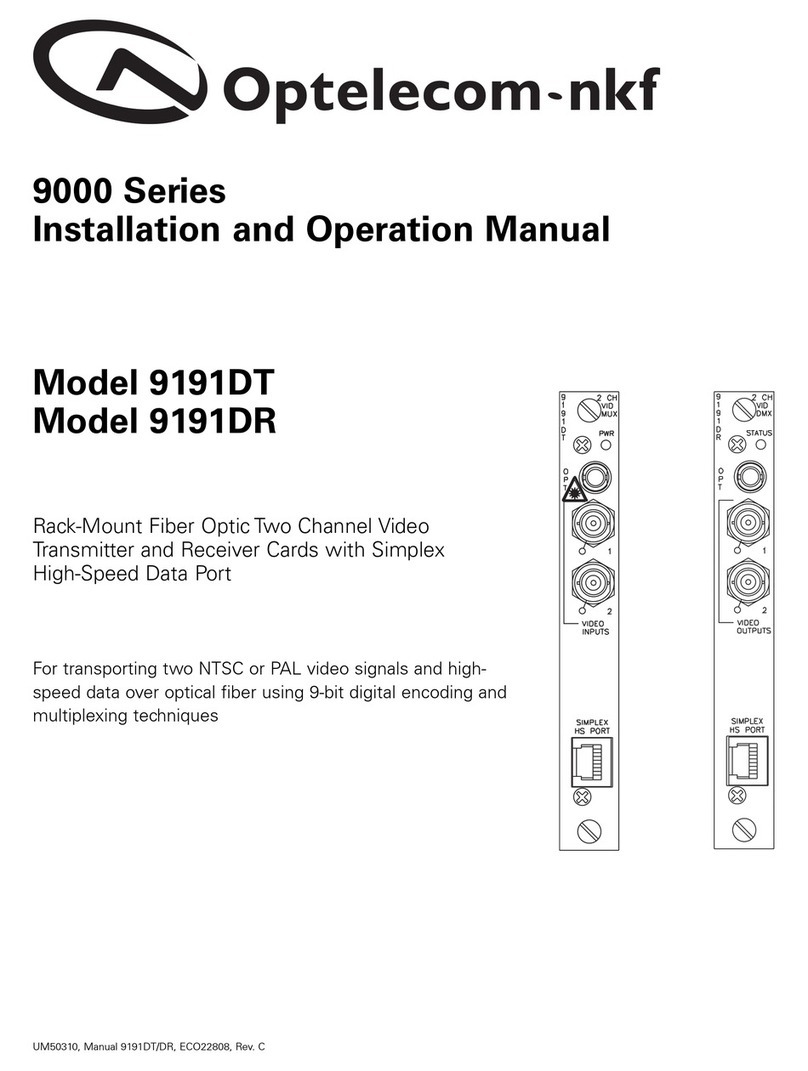

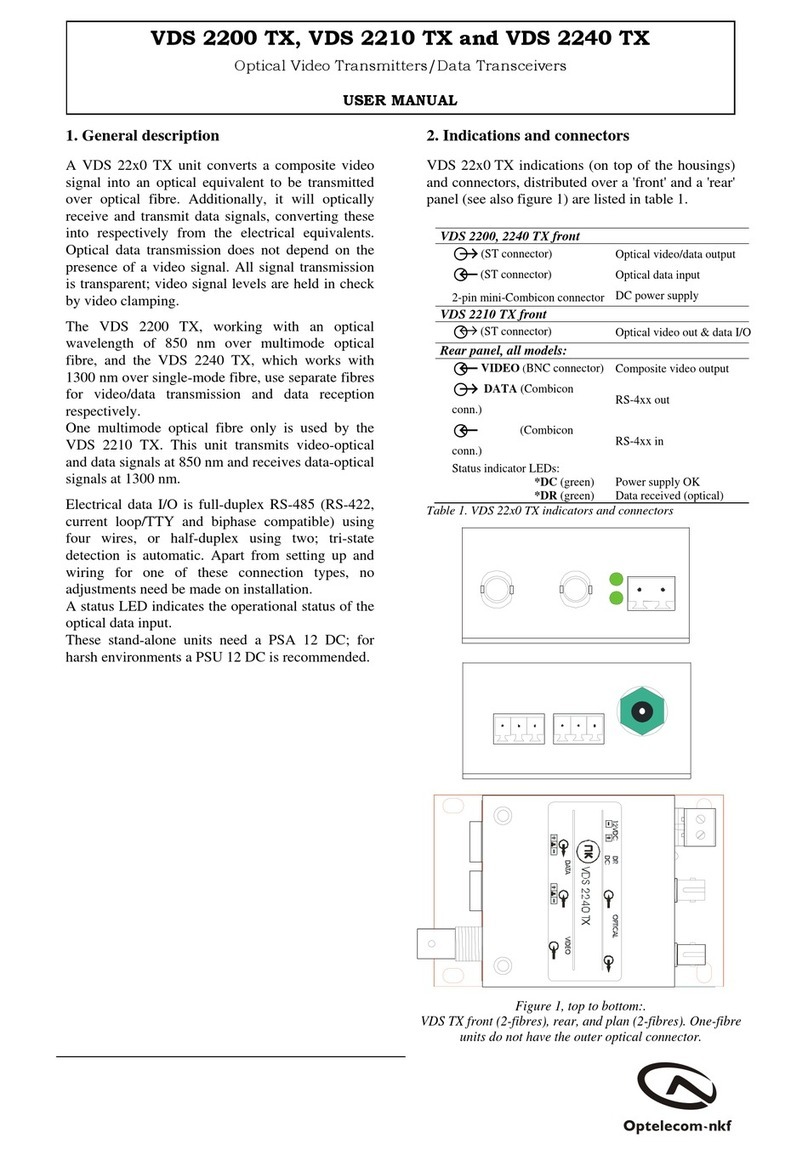

Die optischen Vorrichtungen in diesem Gerät haben Gefahrenstufe 1M. Wie vorgeschrieben durch IEC60825-1 ist der Installateur dafür verantwortlich,

sicherzustellen, dass die unten abgebildeten Schilder an den Orten mit eingeschränktem Zugang, an denen dieses Gerät aufgestellt ist, vorhanden sind.

Diese Baugruppe enthält Teile, die durch elektrostatische Entladungen (ESD) beschädigt werden können. Vorsichtsmaßnahmen

zum Schutz vor elektrostatischer Entladung treffen, wenn Teile oder Baugruppen berührt, ausgebaut oder eingefügt werden.

Das Gestell, in dem diese Einheit eingebaut ist, muss in einem entsprechend klassifizierten NEMA-Schutzgehäuse untergebracht

sein.

Wenn diese Einheit bei besonders hohen Temperaturen betrieben wird, können interne und externe Metallflächen extrem heiß

werden. Es muss darauf geachtet werden, dass diese Einheit in einem Bereich mit eingeschränktem Zugang aufgestellt wird,

damit nur geschultes Wartungspersonal Zugang zur Einheit hat.

Dieses Produkt enthält Laser oder LEDs der Klasse 1M.

• Laserprodukt der Klasse 1M gemäß IEC60825-1:1993+A1+A2

•VORSICHT: Wenn die Bedienungselemente anders als hier beschrieben bzw. andere Einstellungen verwendet werden,

kann es zu schädlicher Strahlenaussetzung kommen.

• Es müssen Vorsichtsmaßnahmen getroffen werden, um Aussetzung an optischer Strahlung zu vermeiden, wenn die Einheit

aus dem Gehäuse genommen oder die Faseroptik von der Einheit getrennt wird.

• In einer Faseroptik-Verbindung dieser Einheit kann auch dann Laserstrahlung vorhanden sein, wenn die Stromversorgung

zur Einheit abgeschaltet wurde.

• Diese Einheit ist zum Einbau an Orten vorgesehen, an denen nur geschultes Personal Zugang zu den Faseroptik-

Verbindungen hat.

• Die Lage aller optischen Verbindungen ist im Abschnitt über die Lage von Anschlüssen und Funktionsweise dieses

Handbuchs zu finden.

• Optische Ausgänge und Wellenlängen sind im Abschnitt mit den technischen Daten dieses Handbuchs zu finden.

Die in diesem abschnitt und auf anderen seiten dieses handbuchs enthaltenen sicherheitsinformationen müssen befolgt werden, wenn diese einheit betrieben,

gewartet oder repariert wird. Falls vorsichtsmassnahmen, warnungen oder anweisungen in diesem handbuch nicht befolgt werden, verstösst dies gegen die

konstruktions, und herstellungsstandards und erfolgt im gegensatz zum vorgesehenen verwendungszweck dieser einheit. Optelecom-NKF übernimmt keine

haftung für das verabsäumnis des kunden, diese sicherheitsanforderungen einzuhalten.

LASER-STRAHLUNG

NICHT DIREKT MIT OPTISCHEN INSTRUMENTEN (LUPEN) ANSEHEN

LASER-PRODUKT DER KLASSE 1M

VORSICHT:

ABGEKLEMMTE OPTISCHE STECKVERBINDER KÖNNEN OPTISCHE ENERGIE FREI SETZEN

NICHT MIT OPTISCHEN INSTRUMENTEN (LUPEN) IN DEN STRAHL BLICKEN.