3

Table of Contents

1 For Safe Use........................................................................... 5

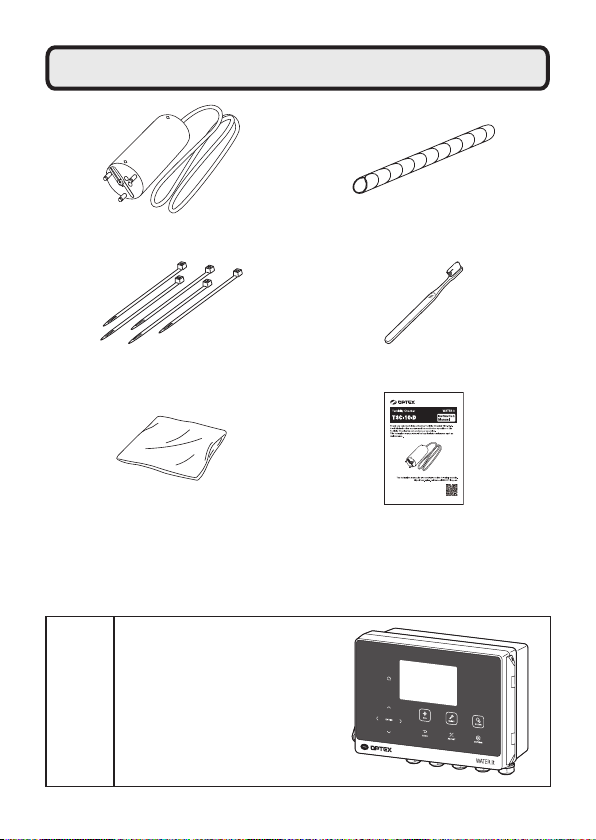

2 Component Name.................................................................. 7

3 Measuring Principle .............................................................. 8

4 Installation.............................................................................. 9

Sensor installation................................................................. 9

Extension of sensor cable................................................... 12

5 Wiring ................................................................................... 13

6 Sensor Setting ..................................................................... 14

Display item (unit selection)................................................ 14

Response time.................................................................... 15

7 4-20 mA Setting ................................................................... 16

Output item selection .......................................................... 16

Upper/lower limit of signal output range.............................. 17

8 Relay Setting........................................................................ 18

Alarm output setting............................................................ 18

Maintenance output setting................................................. 19

Self Checking output setting ............................................... 19

9 Calibration............................................................................ 20

Zero calibration ................................................................... 20

10 Adjustment........................................................................... 23

Offset adjustment................................................................ 23

Span adjustment................................................................. 25

2-point adjustment .............................................................. 26

Adjustment initialization ...................................................... 29