Version 1.1.0 - 2020-08-06 3Translation of original instruction

TH3309 | TH3309D EN

TH3309_TH3309D_GBIVZ.fm

3.2 Assembly................................................................................................................................................ 27

3.3 Unpacking the machine.......................................................................................................................... 27

3.4 Scope of delivery.................................................................................................................................... 27

3.5 Transport ................................................................................................................................................ 27

3.5.1 Load suspension point ........................................................................................................................... 27

3.5.2 Gravity of the machine ........................................................................................................................... 27

3.5.3 Lifting with a forklift................................................................................................................................. 28

3.5.4 Lifting by crane....................................................................................................................................... 29

3.6 Installation and assembly ....................................................................................................................... 30

3.6.1 Requirements regarding the installation site .......................................................................................... 30

3.7 Cleaning the machine............................................................................................................................. 30

3.7.1 Lubrication.............................................................................................................................................. 31

3.8 Anchor-free assembly ............................................................................................................................ 31

3.8.1 Dimension of vibration damper............................................................................................................... 31

3.9 Anchored assembly................................................................................................................................ 32

3.10 First commissioning................................................................................................................................ 32

3.11 Electric three-phase connection............................................................................................................. 32

3.12 Warming up the machine ....................................................................................................................... 33

3.13 Functional check .................................................................................................................................... 33

3.14 Start and stop spindle rotation................................................................................................................ 33

3.15 Warming up the machine ....................................................................................................................... 33

4Operation

4.1 Control and indicating elements ............................................................................................................. 34

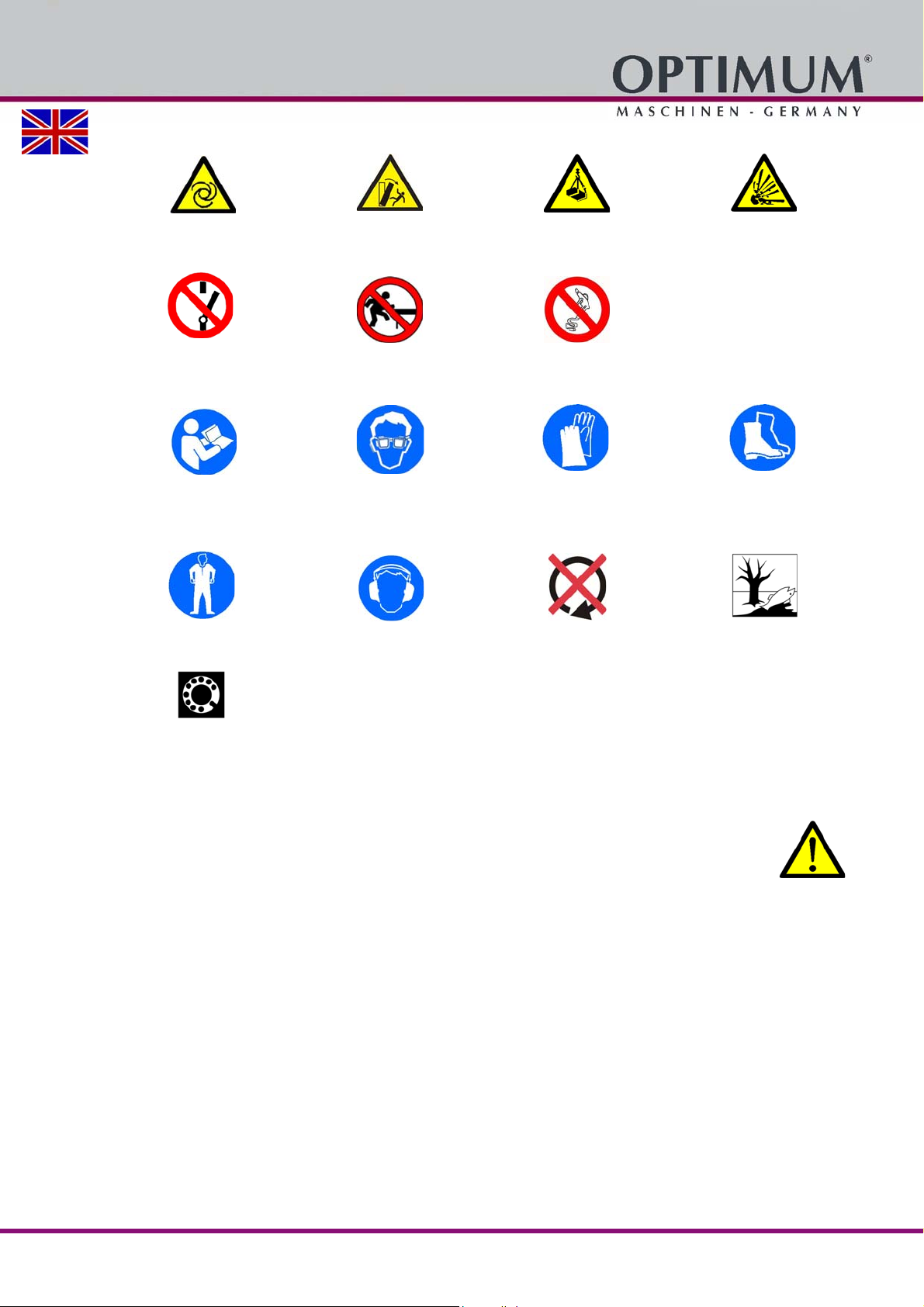

4.2 Safety ..................................................................................................................................................... 35

4.2.1 Overview of the control elements ........................................................................................................... 35

4.2.2 Control elements .................................................................................................................................... 36

4.3 Switching the machine on ...................................................................................................................... 36

4.4 Switching the machine off ...................................................................................................................... 36

4.5 Resetting an emergency stop condition ................................................................................................. 37

4.6 Power failure, Restoring readiness for operation ................................................................................... 37

4.7 Momentary switch, direct run ................................................................................................................. 37

4.8 Foot brake .............................................................................................................................................. 37

4.9 Speed setting ......................................................................................................................................... 37

4.9.1 Speed table TH3309 | TH3309D ............................................................................................................ 37

4.9.2 Position change of the V-belt package................................................................................................... 38

4.10 Turning direction..................................................................................................................................... 39

4.11 Feed ....................................................................................................................................................... 39

4.11.1 Infeed speed........................................................................................................................................... 39

4.11.2 Feed direction......................................................................................................................................... 39

4.12 Tool holder ............................................................................................................................................. 40

4.13 Lathe spindle fixture ............................................................................................................................... 41

4.13.1 Fasten workpiece holder ........................................................................................................................ 42

4.13.2 Lathe chuck ............................................................................................................................................ 42

4.13.3 Speed information, maintenance recommendations, reference speed in accordance with DIN 6386 ... 43

4.13.4 Influencing factors that significantly impact the tensioning force............................................................ 43

4.13.5 Lathe chuck maintenance ...................................................................................................................... 44

4.13.6 Clamping long workpieces ..................................................................................................................... 44

4.13.7 Mounting workpiece holder .................................................................................................................... 45

4.14 Mounting of rests.................................................................................................................................... 45

4.14.1 Follow and steady rests.......................................................................................................................... 45

4.15 Bed insert ............................................................................................................................................... 46

4.16 Setting the feed ...................................................................................................................................... 47

4.17 Adjusting threads.................................................................................................................................... 48

4.17.1 Change gear table.................................................................................................................................. 49