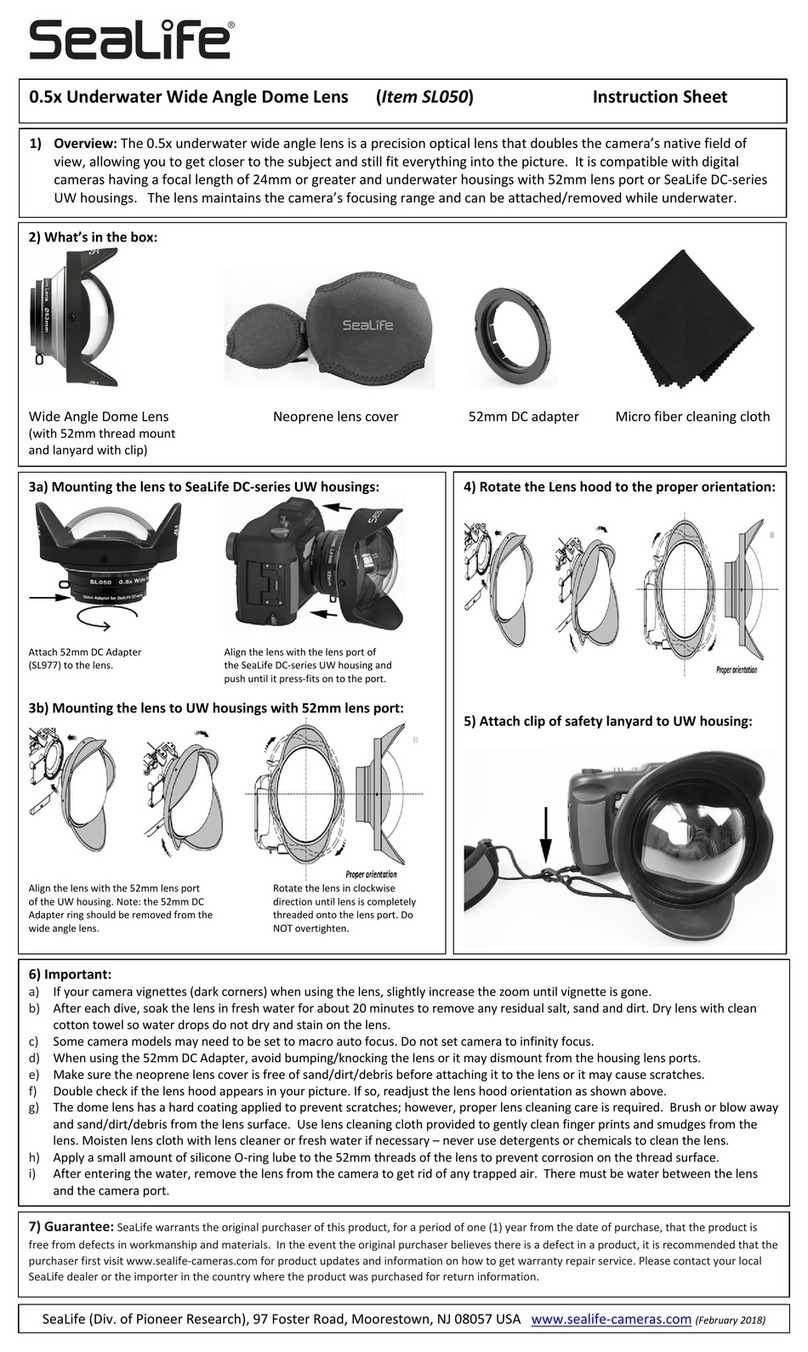

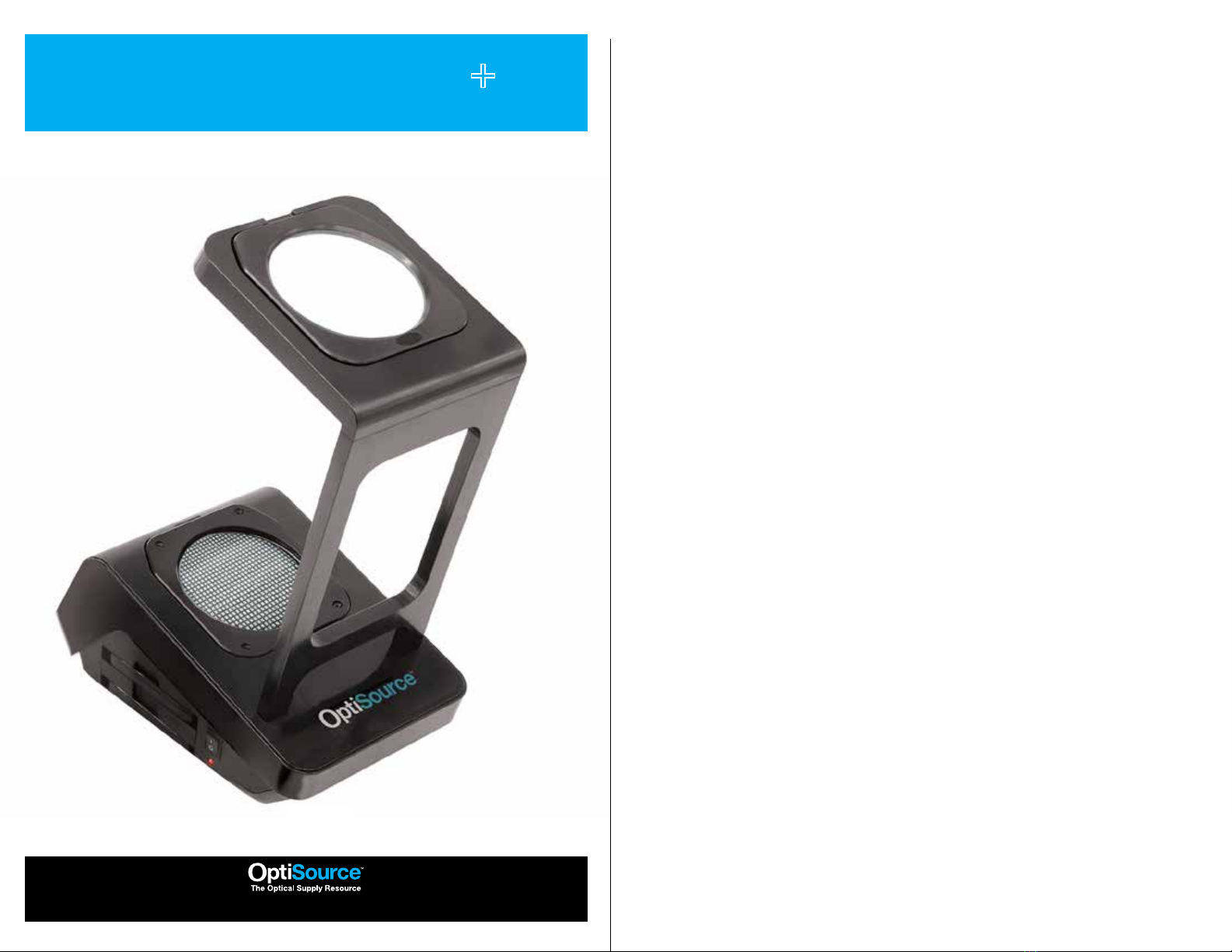

5. Accessories

A. 5X lenses

B. Power adapter

6. Cleaning and maintenance

Keep the lens inspection station dry and clean. Please clean it with lens cleaner or soft cloth.

Caution: please do not clean with alcohol or any corrosive cleanser to avoid damage of the surface.

7. Trouble Shooting Guide

1) Connect the power and turn on the machine. If the light is not on, it may be caused by the bad connection of

the power socket. Rotate the power adapter connection port slightly to check if the machine could light up.

2)When the machine uses the battery power, if the light of the lower inspection window flashes, it means the

voltage is lower than 2.8V, please charge the batteries or use AC power.

If it still can’t work, please contact the Repair department or an authorized distributor.

8. Specifications:

1) Power: AC 100-240V 50-60Hz 0.4A

2) Power Adapter: DC 5V-6.5V 3A (6.5V MAX)

3) Dimension: 230*150*320mm

4) Weight: 1.65kg

5) Optional accessory:18650 rechargeable battery(12580mWh) * 2

Subject to change in design or specifications without advance notice

Version 1.0

- 8 -

If Lens stress has not been dealt with properly, the patient looks forward without any problem, but when he looks

aside, he would feel uncomfortable and unclear view exists. This situation usually appears on the full or half frame

eyeglasses, but not for the rimless ones.

The stress of PC lens can’t be avoided. However, the imaging quality will be much better if the lens stress is

small.

5) Function III - Final Inspection

Steps:

A. Put PAL/Inspection TOP lens on the upper window. The direction mark is aligned with U-shaped groove.

B. Put Inspection BOTTOM lens on the lower window. The direction mark is aligned with U-shaped groove.

C. Put the lens between the inspection lenses. Observe the surface of the lens.

D. Scratching, bubbling and other coating problems can be checked out.

4. Operation Indicator Light

Operation Indicator Light Instructions The order of the

indicator lights

Operation

Indicator 1

Operation

Indicator 2

Operation

Indicator 3 Note At the battery chamber

side, from left to right:

5V DC power, without

battery

flash on on

Without battery,

indicator 1 flashes

:

5V DC Power, with

battery

on off on

The batteries are not

fully charged

Operation Indicator 2:

Full(green)

off on on

charged

Battery Power off off on

connected

:

Booster(green)

- 7 -