9

Safety Information

•

Do NOT use this appliance for other than its intended use.

•

Do NOT probe any openings.

•

Do NOT block or obstruct any openings or vents. (refer ventilation)

•

Do NOT use double adaptors or extension leads.

•

Do NOT overload the shelving. (refer Loading)

•

Do NOT store explosive substances such as aerosol cans with a flammable

propellant in this appliance.

•

Allow adequate ventilation for the refrigeration unit. (Refer ventilation)

•

These appliances are not designed to be stable when moving. Exercise caution

when moving these appliances.

•

Be careful not to touch moving parts and hot surfaces.

•

Ensure the appliance is installed in a stable condition with the front castors locked.

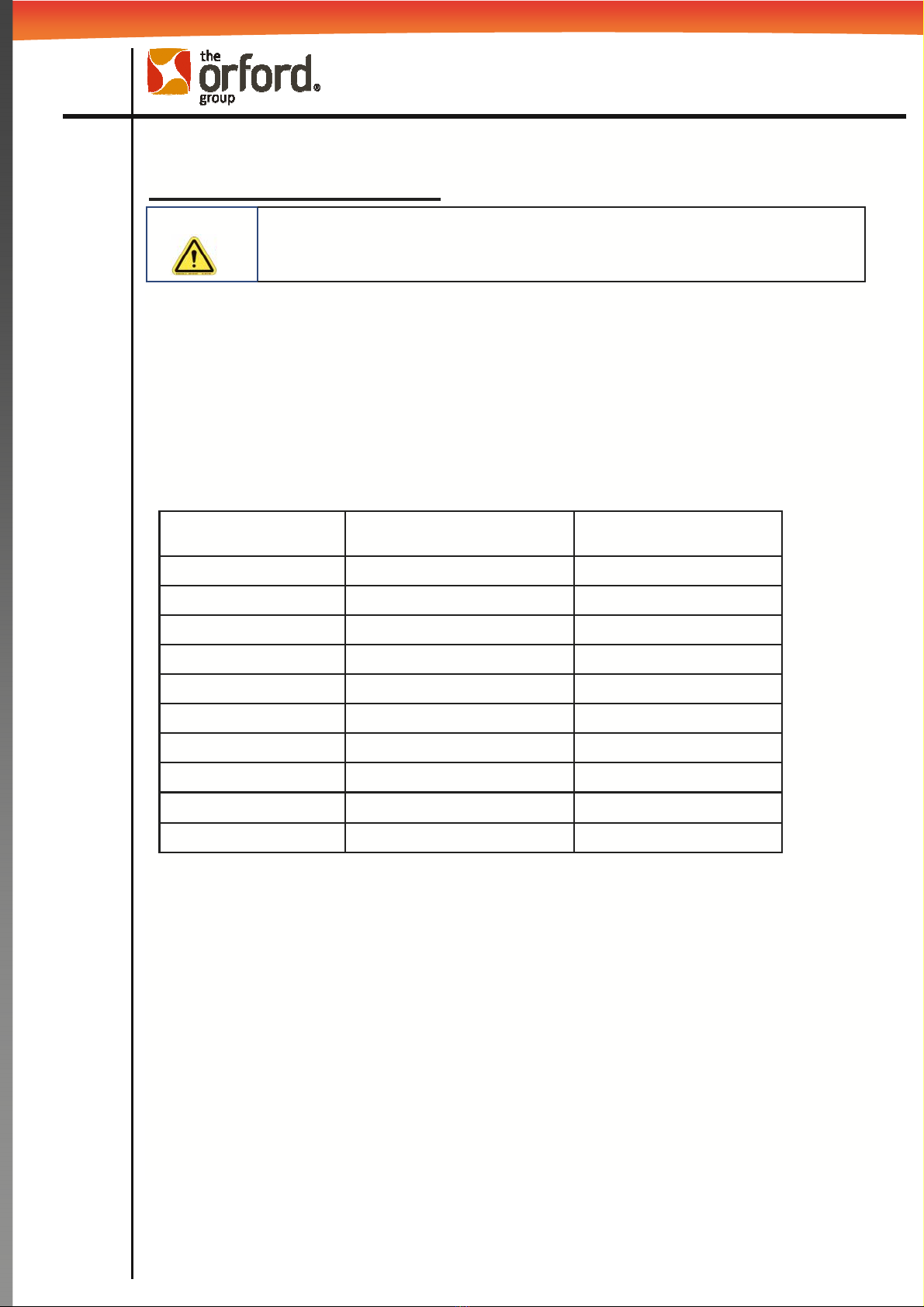

Electrical Requirements

Warning!

The Orford Group does not authorize the use of flammable

refrigerants for servicing these refrigerators and freezers as

injury, loss of life and/or property may result.

This appliance is for indoor use only.

Locating in a location exposed to rain may result in electrical

leakage and electrical shock.

Do NOT overload the power supply. Refer cabinet rating

label for power requirements.

Warning!

Non qualified people must not attempt to work with electrical

connections or attempt to adapt cables or leads. If the supply

cord is damaged, the appliance must be repaired by an

authorised person.

• Make sure the cabinet wiring is connected to the correct source of power.

Maximum current draw is printed on the unit rating tag and where equipment can

be plugged into a General Purpose Outlet (GPO).

• The correct plug top for the required GPO will be supplied as part of the equipment

main power cord.

• Always check line voltage on incoming power to make certain of proper voltage.

The voltage should be within 5% of the voltage printed on the unit rating tag.

The appliance should be connected to a dedicated outlet.

Power Requirements Standard 10 Amp. Power Point 220V-240V 50Hz.

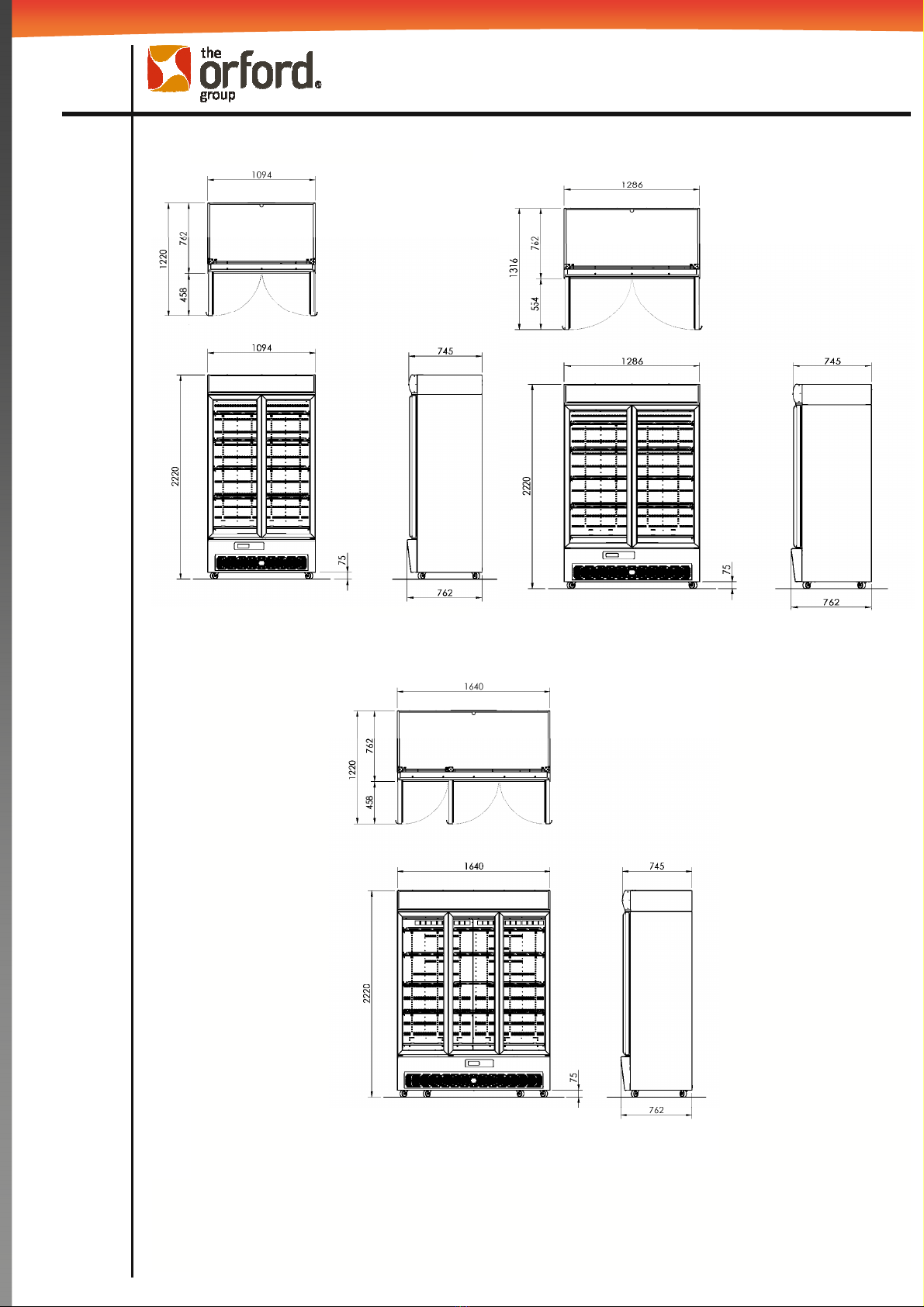

EB30CC-Sn-A / EB36CC-Sn-A / EB45CC-Sn-A

MAN-IO-EBCC-A Rev. 1.0 October 2014 edition