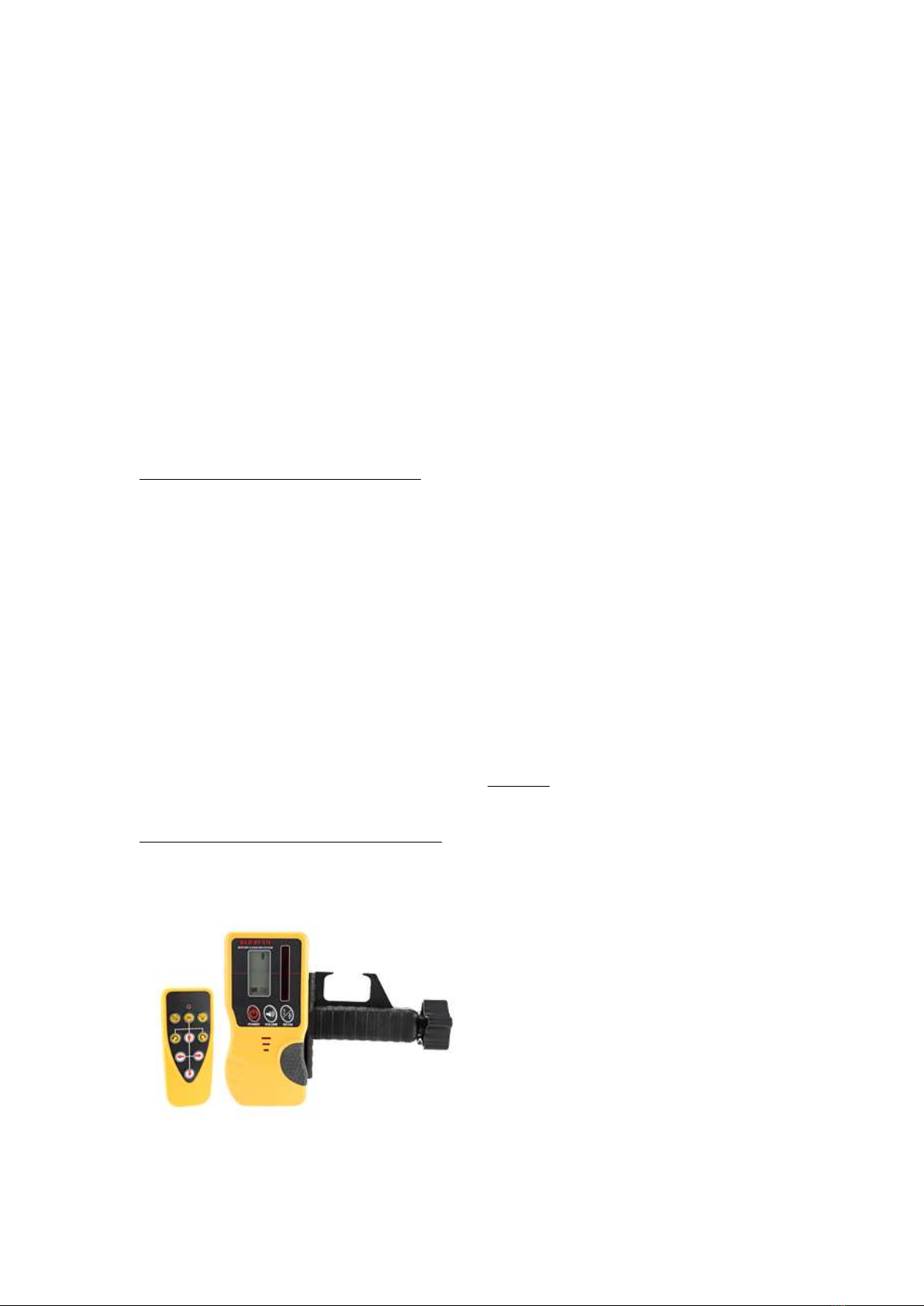

easier to see by eye; but for Exterior Groundworks – run the SP206 at its

maximum speed of 600rpm, which gives the best working range when used

with the supplied Laser Detector. Even with its bright Red beam, a detector

will still be required for most outdoor work.

SCAN function - for Interior setting-out:

The middle yellow button on the right of the keypad is the Scan function. The

User can set a Dot, or 10, 45, 95, 180 degree lines as required & use the two

lower yellow buttons (left hand side of the keypad) to move these "lines"

around the room.

AS THIS LASER AUTO LEVELS BOTH HORIZONTALLY & VERTICALLY,

all the control settings above operate in either mode. (Vertical leveling,

with the laser positioned on its side, is often referred to as "Laydown")

Grading:

This is a DUAL GRADE facility laser level. This means that the SP206 can be

switched to "Manual" (to over-ride the level sensors) and then the User can

set a grade (incline/slope) in the X axis only, Y axis only or both together. The

maximum settable slope is an approx. fall of 700mm over 10m.

For X & Y alignment, please see the case markings on the TOP of the laser

body where an arrow points in the direction of the axis being set.

Setting a single axis slope -

This sets a grade in the X axis.

Procedure – switch ON; the SP206 then auto levels. Press the "Manual"

button on laser's keypad (top left hand side) & the green LED illuminates.

Using the left & right Arrow buttons, set the % slope (fall) required - as

measured on your staff. The same buttons can be found on the Remote

Control.

To return to Auto level, switch the Manual button to OFF (green LED turns

off). The Laser will wait to find true level, then automatically restart, self-

levelled.

Setting Y axis slope -

This sets a grade in the Y axis.

Procedure – switch ON; the SP206 then auto levels. Press the "Manual"