ORKEL Dens-X Compactor User manual

Other ORKEL Garbage Disposal manuals

Popular Garbage Disposal manuals by other brands

Franke

Franke CE-50 User and installation manual

Leafield Environmental

Leafield Environmental Envirobank 140 Installation guidelines

Insinger

Insinger I-6 brochure

KitchenAid

KitchenAid KCDB250G2 parts list

Scheppach

Scheppach HP3000S Translation from the original instruction manual

Zanussi

Zanussi DU 4400 Instruction booklet

Westinghouse

Westinghouse 3/4 HP owner's manual

Haigh

Haigh Quattro Vanguard Original manual

Central Machinery

Central Machinery 70167 Owner's manual & safety instructions

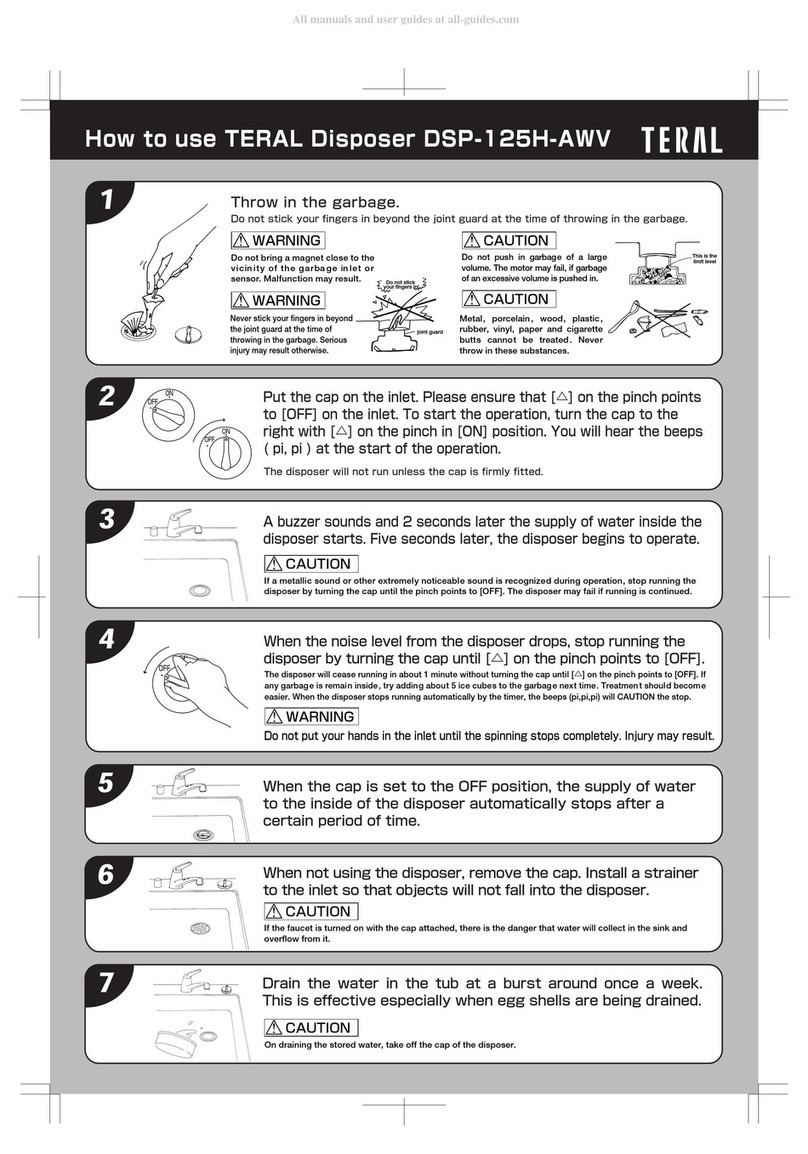

Teral

Teral DSP-125H-AWV Quick start manual

Mistral

Mistral Ultra 10504 Specifications

Atlas Copco

Atlas Copco HC 150 Safety and operating instructions