ORTEC 996 Service manual

Model 996

Timer and Counter

Operating and Service Manual

Printed in U.S.A. ORTEC®Part No. 736820 1202

Manual Revision F

Advanced Measurement Technology, Inc.

a/k/a/ ORTEC®, a subsidiary of AMETEK®, Inc.

WARRANTY

ORTEC* warrants that the items will be delivered free from defects in material or workmanship. ORTEC makes

no other warranties, express or implied, and specifically NO WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE.

ORTEC’s exclusive liability is limited to repairing or replacing at ORTEC’s option, items found by ORTEC to

be defective in workmanship or materials within one year from the date of delivery. ORTEC’s liability on any

claim of any kind, including negligence, loss, or damages arising out of, connected with, or from the performance

or breach thereof, or from the manufacture, sale, delivery, resale, repair, or use of any item or services covered

by this agreement or purchase order, shall in no case exceed the price allocable to the item or service furnished

or any part thereof that gives rise to the claim. In the event ORTEC fails to manufacture or deliver items called

for in this agreement or purchaseorder, ORTEC’s exclusiveliabilityandbuyer’s exclusiveremedy shallbe release

of the buyer from the obligation to pay the purchase price. In no event shall ORTEC be liable for special or

consequential damages. Quality Control

Before being approved for shipment, each ORTEC instrument must pass a stringent set of quality control tests

designed to expose any flaws in materials or workmanship. Permanent records of these tests are maintained for

use in warranty repair and as a source of statistical information for design improvements.

Repair Service

If it becomes necessary to return this instrument for repair, it is essential that Customer Services be contacted in

advance of its return so that a Return Authorization Number can be assigned to the unit. Also, ORTEC must be

informed, either in writing, by telephone [(865) 482-4411] or by facsimile transmission [(865) 483-2133], of the

nature of the fault of the instrument being returned and of the model, serial, and revision ("Rev" on rear panel)

numbers. Failure to do so may cause unnecessary delays in getting the unit repaired. The ORTEC standard

procedure requires that instruments returned for repair pass the same quality control tests that are used for

new-production instruments. Instruments that are returned should be packed so that they will withstand normal

transit handling and must be shipped PREPAID via Air Parcel Post or United Parcel Service to the designated

ORTEC repair center. The address label and the package should include the Return Authorization Number

assigned. Instruments being returned that are damaged in transit due to inadequate packing will berepaired at the

sender's expense, and it will be the sender's responsibility to make claim with the shipper. Instruments not in

warranty should follow the same procedure and ORTEC will provide a quotation.

Damage in Transit

Shipments should be examined immediately upon receipt for evidenceof externalor concealeddamage. Thecarrier

making deliveryshouldbenotifiedimmediatelyofanysuchdamage, sincethecarrier is normallyliable for damage

in shipment. Packing materials, waybills, and other such documentation should be preserved in order to establish

claims. After such notification to the carrier, please notify ORTEC of the circumstances so that assistancecan be

provided in making damage claims and in providing replacement equipment, if necessary.

Copyright © 2002, Advanced Measurement Technology, Inc. All rights reserved.

*ORTEC®is a registered trademark of Advanced Measurement Technology, Inc. All other trademarks used

herein are the property of their respective owners.

iii

CONTENTS

WARRANTY ....................................................................... ii

SAFETY INSTRUCTIONS AND SYMBOLS ............................................... v

SAFETY WARNINGS AND CLEANING INSTRUCTIONS ..................................... vi

1. DESCRIPTION................................................................... 1

1.1. GENERAL .................................................................. 1

2. SPECIFICATIONS ................................................................ 2

2.1. PERFORMANCE ............................................................. 2

2.2. INDICATORS................................................................ 2

2.3. CONTROLSDISPLAY......................................................... 3

2.4. INPUTS .................................................................... 4

2.5. OUTPUTS .................................................................. 4

2.6. INTERFACES ............................................................... 4

2.7. ELECTRICALANDMECHANICAL................................................ 4

2.8. ORDERINGINFORMATION .................................................... 5

3. INSTALLATION .................................................................. 5

3.1. INPUTPOLARITYSELECTION.................................................. 5

3.2. COUNTERINPUTSELECTJUMPER ............................................. 6

3.3. GENERAL .................................................................. 6

3.4. CONNECTIONTOPOWER..................................................... 6

3.5. SIGNALCONNECTIONS....................................................... 6

3.6. OUTPUTCONNECTIONS...................................................... 7

3.7. PRESET TIME OPERATION .................................................... 7

3.8. PRESET COUNT OPERATION .................................................. 7

4. OPERATING INSTRUCTIONS ....................................................... 8

4.1. RS-232-C INTERFACE (MODEL 99X-1) ........................................... 8

4.1.1. 20-mA CURRENT LOOP OUTPUT .......................................... 9

4.1.2. USINGTHE99X-1WITHAPRINTER........................................ 9

4.1.3. INSTALLATION INSTRUCTIONS .......................................... 10

4.2. IEEE-488 (GPIB) INTERFACE (MODEL 99X-2) ..................................... 10

4.2.1. USINGTHE99X-2WITHAPRINTER....................................... 12

4.2.2. INSTALLATION INSTRUCTIONS .......................................... 12

4.3. PRINTLOOPINTERFACE(MODEL99X-3) ....................................... 13

4.3.1. INSTALLATION INSTRUCTIONS .......................................... 14

5. PROGRAMMINGTHE996......................................................... 15

5.1. RS-232-C INTERFACE ....................................................... 15

5.1.1. TERMINALOPERATION ................................................ 15

5.1.2. BASIC PROGRAMMING ................................................. 16

5.2. INTERFACING TO THE IEEE-488 BUS ........................................... 17

5.2.1. HEWLETT-PACKARDCOMPUTEREXAMPLES .............................. 18

5.2.2. IBM-PCPROGRAMMINGEXAMPLES ...................................... 22

APPENDIX A. ASCII COMMANDS TO THE MODULE ...................................... 27

A.1. COMMANDWORDS......................................................... 27

A.2. DATAVALUES ............................................................. 27

iv

A.3. CHECKSUMS .............................................................. 27

A.4. RESPONSE FROM THE MODULE .............................................. 27

A.5. TIMEUNITSUSEDINCOMMANDS............................................. 27

A.6. CATALOGOFCOMMANDSFORTHE996 ....................................... 27

APPENDIX B. RESPONSE RECORDS FROM THE 996 MODULE ............................ 31

B.1. DELIMITINGCHARACTERS................................................... 31

B.2. PERCENT RESPONSE RECORDS .............................................. 31

B.3. DOLLAR RESPONSE RECORDS ............................................... 32

APPENDIX C. OPTIONAL PARTS LIST ................................................. 33

C.1. CABLESANDCONNECTORS ................................................. 33

C.2. ORDERINGINFORMATION ................................................... 33

v

SAFETY INSTRUCTIONS AND SYMBOLS

This manual contains up to three levels of safety instructions that must be observed in order to avoid

personal injury and/or damage to equipment or other property. These are:

DANGER Indicates a hazard that could result in death or serious bodily harm if the safety instruction

is not observed.

WARNING Indicates a hazard that could result in bodily harm if the safety instruction is not observed.

CAUTION Indicates a hazard that could result in property damage if the safety instruction is not

observed.

Please read all safety instructions carefully and make sure you understand them fully before attempting to

use this product.

In addition, the following symbol may appear on the product:

ATTENTION–Refer to Manual

DANGER–High Voltage

Please read all safety instructions carefully and make sure you understand them fully before attempting to

use this product.

vi

DANGER Opening the cover of this instrument is likely to expose dangerous voltages. Disconnect the

instrument from all voltage sources while it is being opened.

WARNING Using this instrument in a manner not specified by the manufacturer may impair the

protection provided by the instrument.

CAUTION To prevent moisture inside of the instrument during external cleaning, use only enough liquid

to dampen the cloth or applicator.

SAFETY WARNINGS AND CLEANING INSTRUCTIONS

Cleaning Instructions

To clean the instrument exterior:

!

Unplug the instrument from the ac power supply.

!

Remove loose dust on the outside of the instrument with a lint-free cloth.

!

Remove remaining dirt with a lint-free cloth dampened in a general-purpose detergent and water

solution. Do not use abrasive cleaners.

!

Allow the instrument to dry completely before reconnecting it to the power source.

vii

This instrument may have been manufactured with round LED indicators

instead of triangular shaped ones as shown.

1

ORTEC MODEL 996

TIMER AND COUNTER

1. DESCRIPTION

1.1. GENERAL

The ORTEC Model 996 Timer and Counter

incorporates a 100-MHz, 8-decade counter and a

blind preset timer. The basic model offers visual

readout via an 8-decade LED display. By plugging

in field-installable options, considerably enhanced

readout and control capability can be added at any

time.

For automated counting applications not requiring

computer interfacing, the standard ORTEC print

loop function is available as a field-installable plug-

in board. In conjunction with an ORTEC Model

777A Printer, this option offers automatic recycling

of the counting and printing of all 8 digits of the

counter'scontents,along withthat of other counters

in the print loop. In place of the 777A, the ORTEC

Model 879 Buffered Interface can be utilized with

the print loop. This solution provides IEEE-488 and

RS-232-C interfaces for all the counters in the print

loop. The Model 879 has the capability,through the

print loop, to start and stop counting, reset, and

read the contents of the counter in the Model 996

along with other counters in the print loop.

The full power of CCNIM™ (Computer Controlled

NIM) is obtainable by adding the IEEE-488 option

or the RS-232-C option. These plug-in boards yield

computer control of all functions normally

selectable from the front panel, including start and

stop count, readout, reset, setting the preset value,

displaying the preset value, displaying the counter

contents, and selecting the desired time base. To

eliminate accidental operator interference, the

computer can disable all front-panel controls in the

remote mode. Computer readout with either of the

two CCNIM™ options includes the contents of the

counter, the preset value, and the current display

mode.The IEEE-488optionalsoreadstheoverflow

status for the counter. Implementationof the IEEE-

488 interface in the Model 996 is compatible with

the NIM/GPIB standard.1The CCNIM options can

directly drive printers having RS-232-C or IEEE-

488 ports.

Excellent flexibility in setting the preset value is

offered by the MN X 10Pselection. The M and N

values provide two-digit precision, while P selects

the decade. Presetscan be chosen in the rangesof

0.01 to 990,000 seconds, 0.01 to 990,000 minutes,

or 1 to 99,000,000 counts. In the external (EXT)

time base mode, the 996 becomes a displayed,

preset counter. The 996 can function as a

displayed, preset timer by changing the position of

a circuit board jumper and using the 0.01-SEC or

0.01-MIN time base.

Both positive and negative sensing inputs to the

counter are available on the front panel. The

negative input is designed to accept standard NIM

fast-negative logic pulses with a fixed threshold of

-250 mV on a 50-

S

input impedance. The negative

input can handle counting ratesupto 100 MHz. The

positive input can accept counting rates up to 25

MHz on a 1000-

S

input impedance. To enhance

the flexibility of the positive input, a precision

discriminator is included. The discriminator

threshold is variable over the range of +100 mV to

+9.5 V using a front-panel, 25-turn trimpot. The

threshold can be adjusted to suit the amplitude of a

specific source of logic pulses or used as a

precision integral discriminator on analog pulses.

For the latter application the TTL logic output of the

discriminator is providedas a test point on the front

panel. This output can be used to trigger an

oscilloscope while viewing the analog signal at the

counter input on the oscilloscope. The oscilloscope

tracewillshowthesignalsthatare beingcountedby

the Model 996, thus permitting a very selective

adjustment of the threshold.

1See: "STANDARD NIM DIGITAL BUS (NIM/GPIS)", DOE/ER-

0173, U.S. NIM committee, August 1983; "IEEE Standard Digital

Interface for Programmable Instrumentation", ANSI/IEEE Std

488-1978, The Institute of Electrical and Electronics Engineers,

345 East 47 Street, New York, NY 10017; and "Codes and

Format Conventions for Use with ANSI/IEEE Std 488-1978",

ANSI/IEEE Std 728-1982, The Institute of Electrical and

Electronics Engineers, 345 East 47 Street, New York, NY 10017.

2

All the commonly used functions are conveniently

accessible on the front panel. Manual control of the

COUNT STOP, and RESET functions is via three

push buttons. The GATE LED is illuminated when

the Model 996 is enabled to count. Selection of the

0.01-s, 0.01-min, or external time base is made by

the TIME BASE push button. In the external mode

the preset counter countsthe events from the front-

panel positive or negative inputs. The DISPLAY

push button switches the display to show the

contents of the counter or the presetstop value. To

change the preset value, the PRESET mode must

first be selected with the DISPLAY push button.

Subsequently,thePRESETSELECTpushbuttonis

usedtochooseM, N, or P for adjustment.Changing

the value of M, N, or P is accomplished with the

PRESET ADVANCE push button. The display

contains LED flags to indicate whether M, N, or P

has been selected, to warn when an overflow has

occurred in the counter, and to advise when the

front-panel controls aredisabled by the computer in

the remote mode.

When the Model 996 is used without a plug-in

option, jumpers on the circuit board can select

automatic recycling of the counting interval with a

display dwell time of either 1 or 10 s at the end of

each counting interval. The plug-in options disable

the dwell/automatic recyclefunction, when enabled

by an external controller.

The counting function of the entire module can be

disabled by holding the GATE input below +1.5 V

using an external signal source. This condition also

turns off the GATE LED. Open circuit or greater

than +3 V at the GATE input allows the instrument

to count if the COUNT mode has been activated.

TheINTERVALoutputofanotherORTECtimercan

perform this function to synchronize the Model 996

counting with the other timer. The INTERVAL

outputs on all ORTEC timers provide nominally +5

V when counting and less than +0.5 V when

counting is inhibited. Interface connectors for the

plug-in IEEE-488, RS-232-C, and print loopoptions

are located on the rear panel. The overflow output

for the counter is also located on the rear panel.

Counting these overflows on another counter

effectively extends the counting capacity of the

Model 996.

The Model 996 derives its power from the ±12 V,

and +6 V supplies in a standardNIM bin with power

supply.

2. SPECIFICATIONS

2.1. PERFORMANCE

COUNT CAPACITY 8 decades for counts ranging

from 0 to 99,999,999.

MAXIMUM COUNTING RATE 100 MHz for

negative input; 25 MHz for positive input.

TIMEBASE 10-MHz clock with minimum preset or

displayed intervals of 0.01 s or 0.01 min.

Synchronizing error is nominally 100 ns. Also

accepts an external input from the counter input

when the EXT (external) mode is selected.

TIME BASE ACCURACY Within ±0.0025% over

the 0-50° C operating temperature range.

PRESET TIME/COUNTS The module stops

counting when the preset value MN X 10Pis

reached on the blind preset register. M and N are

digits ranging from 0 to 9. P is a digit ranging from

0 to 6. With the 0.01-SEC time base, preset times

from 0.01 to 990,000 s can be used. Preset times

from 0.01 to 990,000 min are available using the

0.01-MIN time base. In the EXT time base mode,

preset counts in the range of 1 to 99,000,000 can

be used.

POSITIVE INPUT DISCRIMINATOR Threshold

variable from +100 mV to +9.5 V with a 25-turn

trimpot.

PULSE PAIR RESOLUTION <10 ns for negative

input; <40 ns for positive input.

2.2. INDICATORS

COUNTER DISPLAY 8-digit, 7-segment LED

display with leading zero suppression. When

displaying time, two digits to the right of a decimal

point are included.

OVERFLOW INDICATOR An LED indicator

labeled OVF illuminateswhen the counter exceeds

its capacity of 8 decades. The indicator remains on

until a reset is generated.

3

M, N, AND P INDICATORS Three LED indicators

aid in the selection of the preset value. When the

PRESET display function is activated, the SEL

(select) push button will select which of the three

LEDsisilluminated. When one of theseLEDsison,

that digit of the preset value can be incremented

using the ADV (advance) push button.

DISPLAY Two LEDs labeled COUNTS and

PRESET indicate the information being displayed

in the counter display. The counter or the PRESET

value may be displayed by repeatedly pressing the

DISPLAY push button until the desired LED is

illuminated.

TIMEBASE ThreeLEDsindicatetheselectedtime

base source. By repeatedly pressing the TIME

BASE pushbutton,0.01SEC, 0.01 MIN, or theEXT

mode can be chosen.

GATE A single LED indicates that the entire

instrument is enabled to count. For the GATE LED

tobe illuminated, the module must be placed in the

COUNT mode (either manually or via the interface

option), the GATE input must be above +3 V or

open circuit, and the preset stop condition must not

have been reached.

REMOTE A single LED labeled REM indicates that

the 996 is under computer control and that all front-

panel controls are disabled. This mode is set by the

ENABLE-REMOTE command.

2.3. CONTROLS DISPLAY

Push button selects the contents of the counter or

the PRESET valuefor presentationinthe 8-decade

display. Repeatedly pushing the button alternates

the selection between the two choices as indicated

by the COUNTS and PRESET LEDs.

SEL (Select) Push button chooses the M, N, or

P digit in the display of the preset value. Pushing

the button advancesthe selectionthrough the three

choices as indicated by the illuminated LED. The

SEL push button operates only if the PRESET

mode has been selected by the DISPLAY push

button.

ADV(Advance) Pushbuttonincrementsthepreset

digit selected by the SEL push button once each

time the ADV button is depressed. The M and N

digit ranges are both 0 to 9. The P digit range is

from 0 to 6. The ADV push button operates only if

the PRESET mode has been selected by the

DISPLAY push button.

TIME BASE Each push on this button advances

the selection one step through the three time base

choices (0.01 SEC, 0.01 MIN, and EXT) to

determine the time base source for the preset

register.

STOP This push button stops all sections of the

instrument from counting.

RESET Depressing this button resets the counter

to zero counts and turns off the overflow indicator.

It also clears any counts accumulated in the blind

preset register, but does not change the selected

preset value. When power to the module is turned

on, a RESET is automatically generated.

COUNT Pushing this button enables the counting

condition for the entire instrument, providing the

GATE input is not held below +1.5 V and the preset

value has not been reached.

THRESH ADJ Front-panel mounted, 25-turn

trimpot to adjust the positive input threshold for the

counter. The range is from +100 mV to +9.5 V.

Adjacent test point provides the TTL logic signal

output from the discriminator to facilitate

adjustment using an oscilloscope.

AUTOMATIC RECYCLE WITH DISPLAY DWELL

Normally the Model 996 stops counting at the end

of a counting interval and displays the contents of

the counter until the RESET button is pushed.

Alternatively, an automatic recycle counting mode

can be enabled using jumper W1 on the printed

circuit board. When the automatic recycle mode is

selected, the display dwells for 1 or 10 seconds at

the end of the counting interval. At the end of the

display dwell period, the 996 is reset and the next

counting /display dwell cycle begins. Using jumper

W2 on the printed circuit board, either a 1 - or 10-s

display dwell can be chosen. The display

dwell/automatic recycle mode is disabled

automatically when the 996 is under print loop

control or computer control.

COUNTER/TIMER JUMPER A two-position

jumper (W3) located on the printed circuit board

determines the information accumulated and

displayed by the counter. With W3 in the

COUNTER position, the counter always countsand

displays the events connected to the front-panel

4

input (POS IN, NEG IN). With W3 set to the TIMER

position, the counter counts and displays the time if

either the 0.01 -SEC or the 0.01 - MIN time base is

selected. If the EXT time base is selected, the

counter will count and display the events from the

front-panel inputs (POS IN or NEG IN).

1 CYCLE/ RECYCLE Selection of either the

1 CYCLE or the RECYCLE mode can be made via

an 8-pin DIP switch on the IEEE-488 and the RS-

232-C interface boards. The RECYCLE mode can

be used when the computer is able to respond with

a data transfer when the 996 reaches the preset

value.Upon reachingpresetthe996latchesitsdata

into a buffer, resets the counters, and starts the

next counting interval. This process takes

approximately 50

:

s. The computer reads the data

in the buffer before thenext counting interval ends.

In the 1 CYCLE mode the 996 simply stops

counting and waits for further commands when the

preset value is reached.

2.4. INPUTS

POS IN (Positive Input) Front-panel BNC

connector for the counter input accepts positive

unipolar signals with a minimum width above

threshold of 20nsat a 50% duty cycle. Threshold is

adjustable from +100 mV to +9.5 V via a front-

panel 25-turn trimpot. Zin = 1000

S

to ground; dc

coupled.

NEG IN (Negative Input) Front-panel BNC

connector for the counter input accepts -600 to -

1800 mV fast logic pulseswith a fixed discriminator

threshold of -250 mV. Zin = 50

S

; dc coupled.

Minimum pulse width above threshold is 4 ns.

GATE Front-panel BNC input connector accepts

NIM standard slow-positive logic pulses to control

the counting condition of the entire module. A level

of >+3 V or open circuit allows counting provided

the instrument is in the COUNT mode and has not

reached thepresetvalue, A level of <+1.5 Vinhibits

counting. The driving source must be capable of

sinking 5 mA of positive current during inhibit. The

input is protected to +25 V.

2.5. OUTPUTS

INTERVAL Front-panel output BNC connector

furnishes a positive level during the counting

interval. The level is nominally +5 V when counting

is enabled and <+0.5 V when counting is disabled.

Zo

-

30

S

.

OVFL Rear-panel output BNCconnector provides

a NIM standard slow-positive logic signal each time

the counter overflows its 8-decade capacity. The

signal has a nominal amplitude of +5 V; width

-

20

:

s.

2.6. INTERFACES

PRINT LOOP When the print loop option board is

installed, it furnishes a rear-panel, 14-pin, AMP™

CHAMP™, femaleconnector containing signalsfor

the standard ORTEC daisy chain print loop

operations. This option is field installable. When

connected in a print loop with an ORTEC Model

777A Printer, this option offers automatic recycling

of the counting and printing of all 8 digits of the

counter along with any other counters in the print

loop. If the Model 777A is replaced with an ORTEC

Model 879 Suffered Interface, the print loop will

have IEEE- 488 and RS-232-C interface capability,

allowing the computer to start and stop the

counting, reset the module, and read the contents

of the counter.

IEEE-488 When the IEEE-488 option board is

plugged in, it furnishes a rear-panel, standard,

IEEE-488 bus connector. This 24-pin, AMP™

CHAMP™, female connector allowsthe Model 996

to lie controlled from a computer via the IEEE-488

bus. The field-installable option provides computer

control of the following functions: COUNT, STOP,

RESET, REMOTE, setting the preset value,

selecting the display mode, and selecting the

desired time base. In the remote mode the

computer can disable all front-panel controls.

Computer readout includes: counts, the preset

value, the display mode, and the overflow status.

SERIAL When the RS-232-C option board is

plugged in, it furnishes a rear-panel, 25-pin, male,

D connector containing all signals for standard RS-

232-Ccommunications.It alsocontainsconnections

for 20-mA current loop communications. The field-

installable RS-232-C option provides computer

control of the following functions: COUNT, STOP,

RESET, REMOTE, setting the preset value,

selecting the display mode, and selecting the

desired time base. In the remote mode the

computer can disable all front-panel controls.

Computer readout includes: counts, the preset

value, and the display mode.

5

2.7. ELECTRICAL AND MECHANICAL

DIMENSIONS NIM-standardsingle-width module,

3.43 X 22.13 cm (1.35 X 8.714 in.) front panel per

TID-20893 (Rev).

WEIGHT

Net 0.908 kg (2.0 lb)

Shipping 1.4 kg (3.1 lb)

POWER REQUIRED TheModel 996 andthe plug-

in options derive power from a NIM bin furnishing

±12 V and +6 V. The power required depends on

the installed option as shown in the Power

Requirements Table.

2.8. ORDERING INFORMATION

NOTE: All three interface option boards use the

same position in the module. Only one can be

plugged in at a given time.

996 Basic modulewithout plug-inoptions.

99X-1 RS-232-C Interface option (cable not

included).

99X-2 IEEE-488 Interface option (cable not

included).

99X-3 Print Loop Interface option. Includes

a 772-Cl Print Loop Cable (61 cm

long) with a double-ended connector.

C-75 Female-to-female RS-232-C null

modem cable (3-meter length).

C-80 Male-to-female RS-232-C extension

cable (3-meter length).

C-488-1 IEEE-488 interface cable (1-meter

length).

C-488-4 IEEE-488 Interface cable (4-meter

length).

772-CI-X-S Print Loop Cable with double-ended

connector. Specify the length "X" in

feet.

POWER REQUIREMENTS TABLE

+12 V -12 V +6 V

Basic Model 996 25 mA 50 mA 475 mA

996 plus IEEE-488 option 35 mA 55 mA 1000 mA

996 plus RS-232-C option 45 mA 70 mA 1000 mA

996 plus Print Loop option 25 mA 50 mA 600 mA

3. INSTALLATION

Before inserting the Model 996 into the bin, set the

switches and jumpers for the desired operating

conditions. There are several jumpers inside the

996 that allow the operator to select the mode of

operation and how the time is displayed. The left

side panel must beremoved to gain accesstothese

jumpers. Also, if a communications interface is

installed, an 8-position DIP switch must be set up

correctly for the particular system to which it is

connected.

3.1. INPUT POLARITY SELECTION

The 996 accepts and counts either fast, negative-

logic pulses or slow, positive-logic pulses.

Determine the type of input pulses that will be

furnished and select the correct input BNC to

accommodate the type of pulses.

There are two important points to consider when

supplying signals to the 996: (1) A single pulse

must cross the threshold level only one time.

Signals with overshoot or ringing will be counted

more than once if such anomaliescause the signals

to cross the threshold level. (2) Single pulses with

slow rise and fall times should be as clean as

possible to prevent multiple counting. As a slow

signal approaches the threshold, a small spurious

noise pulse can traverse the threshold level and

return, causing an extra count to be added.

When using the negative inputs, the threshold pot

should be set at

$

1 V. This prevents any accidental

triggering due to high ground currents present at

counting rates of 100 MHz.

6

3.2. COUNTER INPUT SELECT JUMPER

Jumper W3, located on the Counter Board (mother

board), allows flexibility in selecting the input to the

counter with respect to the Time Base Selection

(Fig. 1). The two positions are labeled TIME and

COUNTS. In the Time position, the counter always

counts the time base signals unless the External

time base is selected, in which case the signals at

the front-panel input are counted (POS IN, NEG

IN). With W3 in the TIME position, the counter

always displays the events driving the preset

register. In the COUNTS position, the signals at the

front-panelinputarealwayscountedbythecounter,

regardless of the time base selection. The preset

register becomes a blind timer in this position

unless the External time base is selected.

The 996 is shipped from the factory with W3 set to

the COUNT position.

3.3. GENERAL

The Model 996 Timer and Counter operates on ±12

V and +6 V power furnished from a NIM-standard

bin and power supply such as the ORTEC

4001/4002D Series.

3.4. CONNECTION TO POWER

Always turn off the bin power supply before

inserting or removing any modules. The power

supply voltage should be checked after all modules

have been inserted. The 4001/4002D series has

test points on the power supply control panel to

permit monitoring of the dc voltages.

When power is applied to the 996, an automatic

reset function clears the counters to zero and

provides a standard set of start-up conditions: (1)

display select set to COUNTS; (2) preset values of

M, N, and P set to zero; and (3) time base select

set to 0.01 SEC.

3.5. SIGNAL CONNECTIONS

COUNTER INPUT The 996 accepts and counts,

either fast-negative logic pulses or positive pulses

with an amplitude from 0.1 to 10 V. The negative

input threshold is fixed at -250 mV. The positive

input has a front-panel threshold adjustment that is

variable from +100 mV to +9.5 V. A test point is

included on the front panel to facilitate the

adjustment process. For positive logic pulses, the

threshold should be set well above the noise level

of the input. When used with a linear signal as the

input, the threshold should be set just above the

noise level.

7

GATE INPUT A gate input signal or dc level can

be connectedto the 996 through the GATE input on

the front panel. With no input to this BNC, or with a

voltage level >+3 V, the 996 is enabled to accept

counts through the inputs on the front panel. To

disable the timer and the counter, the input at this

connector must be pulled below +1.5 V. To do this,

the driving source must becapable of sinking 5 mA

of current from the GATE input circuitry.

3.6. OUTPUT CONNECTIONS

INTERVAL OUTPUT A dc level that follows the

condition of the counting gate is available at this

front-panel connector. When the counting gate is

enabled, the dc level is nominally at +5 V. When

counting is inhibited (by gating, by having reached

preset, or by being stopped manually or remotely),

the dc level is nominally at 0 V. This output can be

used to gate other counters.

OVERFLOW OUTPUT The counter overflow

output signals are available through the BNC

connectorlocatedontherearpanel.Aslow-positive

logic signal (nominally +5 V, 20

:

s) appears at the

connector each time the contents of the counter

change from 99,999,999to 0. Theoutput signal can

be used as the input to another counter to increase

the total counting capacity beyond eight decades.

3.7. PRESET TIME OPERATION

The Model 996 is designed for standard operation

as a counter that accumulates counts for a fixed

period of time (selected by the operator). At the end

of this time interval, it will stop and hold the data

until it is reset manually,or it can dwell at the preset

stop for a selected amount of time in which the data

can be read. It then resets automatically and

repeats the timingcycle. The useof the GATEinput

is optional depending on the application.

Determine the time interval required for the

collection of counts. If preset time is not desired,

the preset can be disabled by selecting a value of

zero for M and N, and the counting interval can be

controlledusingtheCOUNTandSTOPpush-button

switches on the front panel.

There are two internal time bases to select from:

0.01 seconds and 0.01 minutes. The choice is

made by pressing the Time Base Select push

button until the LED indicator for the desired time

base is lighted.

To preset the time interval, select PRESET as the

displayed value. Press the Select push button until

the LED indicator for the M register is lighted. Next,

press the Advance push button until the correct

value for M appears in the display. Pressthe Select

push button and repeat theabove procedure for the

values of N and P. The selected value is in the

format of MN × 10P, where MN is a number from 01

to 99 and P represents the power of 10 by which

MN is multiplied. For example, to select a preset

time of 15.00 seconds select an M value of 1, an N

value of 5, and a value of 2 for P, which represents

15 × 102ticks of the 0.01-second time base.

The dwell period at the end of the preset interval is

controlled by two jumpers, W1 and W2 (Fig. 1).

With W1 in the Off position, the dwell function is

disabled and the data collected will be displayed

until a manual reset is initiated. With W1 in the On

position, the data will be displayed for either 1

second or 10 seconds, depending on the setting of

W2. At the end of the dwell time, an automatic

reset is generated, and the counting cycle will be

repeated. The dwell function is automatically

disabled when an output option board is enabled to

control the 996.

To monitor the data collected during a counting

period, press the Display Select until the LED

indicating COUNTS is lighted.

To start a counting cycle, press the STOP push

button, then press the RESET push button, and

then press the COUNT push button. The counting

can be halted at any time by pressing the STOP

push button.

If desired the cycle can be resumed from the point

of interruption by pressing the COUNT push button

without pressing RESET.

3.8. PRESET COUNT OPERATION

To select the preset count mode of operation, press

the Time Base Select push button until the LED

representing the External made is lighted. Now the

input to the preset register is taken from the front-

panel counter inputs(POS IN, NEG IN). The preset

value selection is identical to the selection of the

time interval except that the preset value is in units

of input counts rather than units of time.

8

4. OPERATING INSTRUCTIONS

There are three interfaces available for the module

to facilitate the integration into a system

environment: (1) the RS-232-C Serial interface

which includes a 20-mA current loop circuit, (2) the

IEEE-488 (GPIB) interface (1978 standard digital

interface bus), and (3) the ORTEC standard print

loop interface. Each of these interfaces is a

separate plug-in card that is easily installed in the

field.

4.1. RS-232-C INTERFACE (MODEL 99X-1)

This Serial Communications Interface conforms to

the EIA RS-232-C Standard and contains all the

circuitry needed to communicate with most ASCII

terminals and with most computers equipped with a

Serial Communications Port. The connection is

made with a standard 25-pin, male "D" connector

mounted directly to the interface printed wiring

board (PWB). The connector is accessible through

a slot in the rear panel of the module. This

connector is wired as a DTE (data terminal

equipment) device as defined in the RS-232-C

standard. The 20-mA current signals are also

included on this connector.

The signal connections are shown in Table 1. The

signal names in upper case are the 20-mA current

connections and the RS-232-C signal names are

shown in lower case.

When this interface is connected to another DTE

device such as a computer or terminal, a null

modem cable must be used to match the proper

signals between the two devices. These cables are

available at most computer equipment suppliers or

directly from ORTEC. (See Appendix C, Optional

Parts List.) The connections of the null modem

cable are given in Table 2.

The serial option is a full-duplex, asynchronous

communications interface with a selectable baud

rate from 50 to 19,200. The baud rate selection is

made via a 4-position DIP switch located on the

PWB (Fig. 2). The baud rate selected must match

exactly the baud rate of the device to which the

module is connected. The switch settings are given

in Table 3.

In addition to the baud rate selection, the format of

the data bits (ASCII characters) must also be set to

matchthedevicetowhichthemoduleisconnected.

Toaccomplishthis, an8-positionDIPswitch(Fig.2)

9

is provided to allow the operator to select the

number of databits, parity enable or disable, odd or

even parity if enabled, and either one or two stop

bits. These must match the device to which the

module is connected. Table 4 defines these

selections.

The 99X-1 option is shipped from the factory with

the following settings:

1 .Character length set to 8 bits.

2. Parity check and generation disabled.

3. Parity selection set to even.

4. Stop bit selection set for 1.

5. Baud rate set for 9600.

6. One-cycle mode selected.

7. Counter/Timer selected.

8. NORMAL.

4.1.1. 20-mA CURRENT LOOP OUTPUT

The 20-mA current loop operates in exactly the

same way as the RS-232-C. All switch selections

apply equally to the 20-mA current loop

communications. The major difference in the two

modesistheelectricalcharacteristicsof thesignals.

The RS-232-C uses a change in voltage to transmit

and receive data, and the 20-mA current loop uses

a change in current to transmit and receive data.

The current loop is optically coupled to the module

and can be made to be either active (current for the

loop supplied by the module) or passive (current for

the loop supplied by the connected device) by

changing a set of jumpers on the interface board

(Fig. 2). The transmit and receive loops can be

individually selected to be active or passive. The

module is factory-set at shipment with both the

transmit and receive loops set for active. The

transmit andreceivesignalsareincluded in the RS-

232-C connector. A special cable is needed when

usingthe20-mAcurrent looptoconnect themodule

to a computer or terminal. This cable is available

from ORTEC (Appendix C, Optional Parts List).

4.1.2. USING THE 99X-1 WITH A PRINTER

ByplacingthePRINTONLY-NORMAL(S2-8)tothe

PRINTONLYposition,the99X-1Interfacewilldrive

a printer with an RS-232-C interface directly. This

allows the module to generate a hard-copy of the

10

data collected without the need for commandsfrom

a computer or keyboard. When the interface is in-

stalledinaCounter/Timerandthemoduleisstarted

with the Count control, each time the preset value

is reached the data is automatically transferred to a

printer. If the Recycle mode is selected (S2-6 Off),

the Counter data is cleared and a new cycle is

started immediately. If the One Cycle mode is

selected(S2-6 On), the counter willhaltuntilareset

is generated either by the-front-panel Reset switch

or by the Dwell time expiring, at which time a new

counting cycle will begin.

When the interface is installed in a Counter Only

module, a counting cycle is started by the front-

panel Count control. When the counting cycle is

stopped either by pressing the Stop control or by

bringing the Master Enable (or Gate) input low, the

data which has accumulated in the counter will be

transferred to the printer. If the Recycle mode is

selected,thecounter willbeclearedand a newdata

collection cycle started as soon as the counter is

enabled either by the Count control if the counting

wasterminated by the Stop switch, orby the Master

Enable (or Gate) going high if the counting was

stopped by this signal. If the One Cycle mode is

selected, the counter will continue counting from

the point of interruption without being reset when

reenabled to count.

When power is applied to the module, the Model

Number of the Module andthe firmware version will

be printed. When any of the mode switches are

changed, the module must be powered up again

before the changes are recognized.

4.1.3. INSTALLATION INSTRUCTIONS

To install the RS-232-C interface follow the steps

listed below:

1. Remove the left and right side plates from the

module.

2. Replace the two 5/8" metal stand-offs on the

printed circuit board in the module with the two

1/2" stand-offs included in the mounting kit for

the 99X-1 Interface Board.

3. On the interface board, set the switches to the

desired positions using Tables 3 and 4to match

the device to which it will be connected.

4 Install the interface board into the module,

sliding the RS-232-C connector through the slot

in the rear panel of the module first and align

the 40-pin connector on the back of the board

with the pins provided on the counter board.

Use care to ensure proper match-up of

connector and pins.

5. Install the two mounting screws into the

standoffs provided on the counter board.

6. Replace side panels and installation is

complete.

4.2. IEEE-488 (GPIB) INTERFACE

(MODEL 99X-2)

The IEEE-488-1978 standard bus is a byte-serial,

bit parallel interface system established primarily

for the transfer of data and commands between the

components of an instrumentation network. The

system is defined for no more than 15 devices,

interconnected by passive cabling, whose total

transmission length does not exceed 20 meters.

Data rates through any of the 16 signal lines that

comprise the bus must be <1 M-byte/s and consist

of digital data only. The busis connected in parallel

to all components of the system and is designed to

ensure reliable data transfer throughout the

network.

Eight lines(DIO1-DIO8) are used for the transfer of

data betweenthe components of the system. Three

lines (DAV, NRFD, and NDAC) areusedastransfer

control. The remaining five lines (IFC, ATN, SRQ,

REN, and EOI) are for bus management. These

lines may employ either open-collector or tri-state

drivers as defined by the IEEE-488-1978 standard.

Information is transmitted over the eight data lines

underdirectsupervisionof thethreetransfercontrol

lines. Transfer proceedsas fast as the components

of the system can respond, but no faster than the

slowest device currentlyaddressedbythe bus. This

permits multiple data transfers to more than one

device on the bus at a time.

Active devices connected into the system may be

talkers, listeners, controllers, or a combination of

the three, but no more than one device may be

designated as a talker at any given time. The

controller determines the role of each of the

devices by sending out an address of the device to

be defined. Addresses of the devices are set at the

time of system configuration (before power is

applied) by means of an 8- position DIP switch.

Sections 1 thru 5 of switch 1 are used for the

address selection (Table 5).

The following are descriptions for the 16 bus lines

defined in the IEEE-488 bus.

11

DIO 1 THROUGH DIO 8 (DATA INPUT/OUTPUT)

These bidirectional lines are used to transfer data

between devices. Data is asynchronous and

generallybidirectional.Thelinescarryeitherdataor

address information, depending on the state of the

ATN line.

DAV (Data Valid) One of the three transfer control

lines used to indicate that data is available on the

DIO lines.

NRFD (Not Read For Data) Another transfer

control line used to indicate that all devices are

ready to accept data.

NDAC (Not Data Accepted) The third transfer

control line that indicates the acceptance of data by

all devices.

ATN (Attention) A bus management line used to

indicate the type of data on the data lines. When

the ATN line is asserted, DIO 1-8 carry address or

commands.WhenATN is false, the data linescarry

only data.

IFC (interface Clear) A bus management line

which is used to place the system in a known state

for system initialization.

SRO (Service Request) A bus management line

used to indicate a need for service by a device in

the system.

REN (Remote Enable) A bus management line

used to select either local or remote control of each

device.

EOI (End Or Identify) The fifth bus management

line used to indicate the end of a multiple-byte

transfer sequence. This lineis asserted with the last

byte of a data record.

The IEEE-488 (GPIB) interface is a separate PWB

that plugsinto the module counter board andis held

in place with two screws. The connector containing

the signals for bus communications is mounted to

the board and is accessible through the rear panel

of the module. The placement of the connector isin

accordance with the Standard NIM Digital Bus

(NIM/ GPIB) with pin 1 of the connector to the top

of the module.

When power is applied to the module, a series of

self-test routines is executed to test certain parts of

the module. A response record is created to show

the results of the tests. This response record must

be read by the bus controller before the module will

accept any command. A service request (SRQ) is

issued to notify the controller that service is

required before commands can be accepted.

Commandssent to the module must be terminated

with ASCII (carriage return and line feed)

characters. For every command received by the

module, a response record is returned and must be

acceptedbythecontrollerbeforeanothercommand

can be issued. In case of a SHOW command to the

module, two response records must be read by the

controller.Allresponserecordsfromthemodulewill

be terminated with a carriage-return-line feed

sequence with the EOI line asserted along with the

line feed character.

Table 5 shows the switch configuration for address

selection of the device on the bus (Fig. 3).

The address selected is the total of the switches set

to the Off position. For example, to select an

address of 25, switches 1 (1), 4 (8), and 5 (16)

should be set to the Off position. The One

Cycle/Recycle switch determines the action that

occurswhen the counters reach a preset condition.

In the One Cycle mode, the counters will stop at

preset and hold the data until reset manually or

remotely. In the Recycle mode, the contents of the

counterswill betransferredtoabuffer,thecounters

will be reset, and another counting interval will be

started immediately.

12

4.2.1. USING THE 99X-2 WITH A PRINTER

ByplacingthePRINTONLY-NORMAL(S2-8)tothe

PRINTONLYposition,the99X-2Interfacewilldrive

a printer with an IEEE-488 (GPIB) interface directly

if the printer is addressable as a Listen Only

device. A bus controller is not needed for this

operation, but only one Counting module can be

connected to the printer. This will allow the module

to generate a hard-copy of the data collected by

controlling the module with thefront-panel controls.

Whentheinter-faceisinstalledinaCounter/Timer,

and started by the Count control, each time the

preset value is reached the data is automatically

transferred to a printer. If the Recycle mode is

selected(S2-6 Off), the Counter data isclearedand

anewcycleisstartedimmediately.If theOneCycle

mode is selected (S2-6 On), the counter will halt

until a reset is generated either by the front-panel

Reset switch or by the Dwell time expiring, at which

time a new counting cycle will begin.

When the interface is installed in a Counter Only

module, a counting cycle is started by the front-

panel Count control. When the counting cycle is

stopped either by pressing the Stop control or by

bringing the Master Enable (or Gate) input low, the

data which has accumulated in the counter will be

transferred to the printer. If the Recycle mode is

selected, thecounterwillbeclearedand a new data

collection cycle started as soon as the counter is

enabled either by the Count control if the counting

wasterminated by the Stop switch, or by theMaster

Enable (or Gate) going high if the counting was

stopped by this signal. If the One Cycle mode is

selected, the counter will continue counting from

the point of interruption without being reset when

reenabled to count.

When power is applied to the module, the Model

Number of the Module and the firmwareversionwill

be printed. When any of the mode switches are

changed, the module must be powered up again

before the changes are recognized.

4.2.2. INSTALLATION INSTRUCTIONS

To install the IEEE-488 (GPIB) interface follow the

steps listed below:

1. Remove the left side plate from the module.

2. Remove the right side panel.

3. On the interface board, set the switches to the

desired positions using Table 5. Set switch 7 to

Counter/Timer.

13

4 Install the interface board into the module,

sliding the IEEE-488 (GPIB) connector through

the slot in the rear panel of the module first and

align the 40-pin connector on the back of the

board with the pins provided on the counter

board. Use care to ensure proper match-up of

connector and pins.

5. Install the two mounting screws into the stand-

offs provided on the counter board.

6. Replacesidepanelsandinstallationiscomplete.

4.3. PRINT LOOP INTERFACE

(MODEL 99X-3)

With this interface the module can be included in a

print loop with the other counters and timers from

ORTEC. Up to 50 counters can be included in a

counting system with one controller, such as the

Model 879 Buffered Interface, providing the

interface from the loop to a computer or printout

device.

A four-position DIP switch (Fig. 4) is located on the

PWB to select one of the three operating modes:

Master, Slave, or Normal. This switch determines

the role of the individual modules when contained

in a counting system. As a Master, the module

drives the system gate and the system reset lines

but does not respond to a system gate driven by

another device. As a Slave, the module does not

drive the system gate or the system reset signals

but does respond to both. In the Normal position,

the module does not drive or respond to the system

gate or system reset signals. When used with a

Model 879 controller module the usual operating

mode would be the Slave mode.

There are two 2-position jumpers (W1 and W2)

located on the PWB which are labeled DUAL and

SINGLE. These jumpers must be set to match the

number of counterson the mother board into which

the interface boards are connected. If used with the

Model 994 or 995, the jumpers must be set to the

DUAL position. If used with the Model 996 or 997,

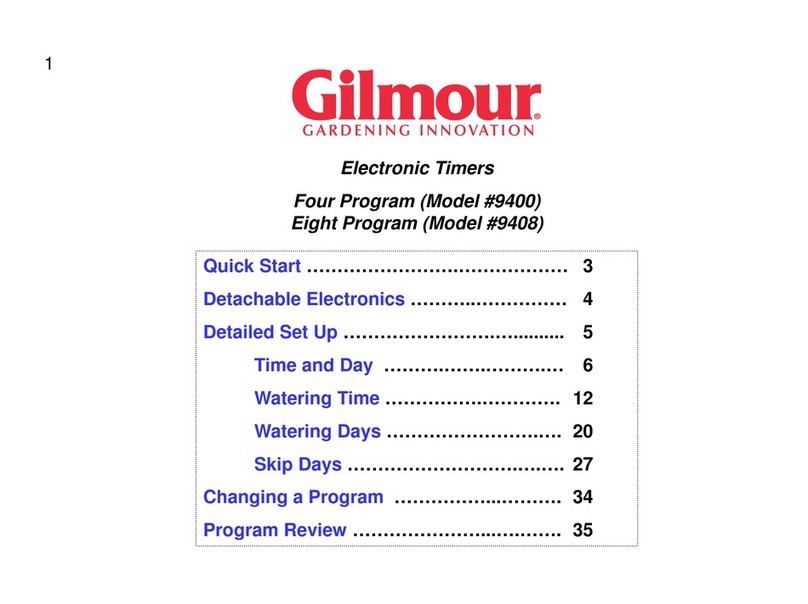

the jumpers must be in the SINGLE position.

Table of contents