OSAI OPENcontrol Installation guide

OPENcontrol - Technical overview

osaicnc.com

Table of contents

OPENcontrol - Overview 3

OSAI Numerical Controls are “modular units” 3

Hardware scalability 3

Software scalability 5

The embedded SoftPLC 6

Standard ready-to use Machine Logic 7

WinNBI 7

Process Controller 8

IsoView 9

Internationalization 9

Connectivity 9

Custom Operator Interfaces 9

OPENcontrol for Metal Cutting and Milling 9

OPENCut – Plasma and Oxyfuel cutting 10

OPENCut – Laser cutting 13

OPENMill - Millling machines software 14

Software Key Features

Axes Management 16

Axes Motion 17

Motion Features 20

Tool Centre Point (TCP) 21

High Speed Machining 23

Virtualization 23

Multi-Axis Electronic Cam 24

Volumetric and Cross Compensation, Axis Calibration 25

OPENcontrol Technical overview

1

List of G-codes 26

CNC Ofine Simulator 28

Hardware

OPENcontrol models 29

OPEN-XS 29

OPEN-M, OPEN-XL, OPEN-XLi 34

Operator Panels 38

OPENconsole 38

OPENconsole COMPACT 15’’ 43

Industrial Monitors with Touch Screen 45

TOP5 – Remote Operator Console 47

OD700 Servodrives & Motors 48

YASKAWA combined Spindle & Servo System 51

Input/Output Modules 54

OPENrio SL I/O Modules 54

OPENrio E901 - PWM module for Laser 56

OPENrio V-200 - Bus coupler and modules 58

CNC Turnkey Solution 60

2

OPENcontrol - Overview

OPENcontrol is a comprehensive product line for automation, consisting of a full range of

hardware and software solutions addressing the most diverse application requirements.

The central unit can be chosen within the complete OPENcontrol CNC family, where

several models of Numerical Controls are available according to machine requirements.

The CNC range starts from OPEN-XS, characterized by a compact design and a competitive

price/performance ratio, up to the powerful OPEN-XLi, designed to handle complete

manufacturing processes.

The advanced OPENcontrol software, designed to be applied in different industry sectors,

simplies the applications management in several technology markets, from Laser and

Plasma cutting to metal chip removal, as well as the advanced built-in software CNC

functions simplify panel and solid wood machining.

The OPENcontrol family includes:

Control Units acting as CNC, GMC or PLC

Operator Panels, Industrial Monitors

Modular I/O systems

Servo-drives and servo-motors

Industrial PCs

OSAI Numerical Controls are “modular units”

The OPENcontrol platform is a modular set of hardware and software elements, or

“building blocks”, which can be combined to suit every application requirement. This

design choice allows the system functionalities upgrade, adding new software or hardware

functions incrementally, with no need to change the system architecture.

Hardware scalability

Several interchangeable Control Units with different CPUs, ensure the appropriate

computational power required by the application.

Different CNC congurations allow the adoption of the best solution for the machine,

maintaining the same software:

• One single hardware module (CNC) where the real-time and the HMI components

coexist, both running on the same real time Operating System.

• Two independent hardware modules connected through network, one for real-time

(CNC) and the other (PC) for the remote Operator’s Interface.

• One single hardware module (CNC) where the real-time and the HMI run independently

on two separated Operating Systems. One dedicated to the real-time software, the

second to run the operator interface software (Dual Operating System).

All configurations can be further expanded, distributing the HMI software on more

stations (PCs) over the network.

OPENcontrol Technical overview

3

Single module conguration

Conguration with two independent HW, CNC and PC

The wide availability of digital fieldbuses extends the OPENcontrol hardware

flexibility. OPENcontrol reaches the best performances combining OSAI EtherCAT

or Mechatrolink III modules, but the central unit provides more fieldbuses.

EtherCAT (SoE and CoE profiles), Mechatrolink III, Mechatrolink I and II, OS-Wire (OSAI

custom), Profibus and CANopen allow the connection to a wide variety of peripherals

whether they are servo-drives, I/O modules or special devices.

The Ethernet support (with TCP/IP protocol), standard on all models, is the basis for

connecting all components of the family. It allows exchange of information between

different nodes and also, where necessary, the monitoring of several systems as well as

support from a remote location (remote service) and communication with supervisory

systems.

4

Software scalability

The different solutions adopted for the Operating System configuration of the CNC

are an important aspect that points to the scalability of OPENcontrol.

Windows CE is the real time Operating System used for OPENcontrol product line:

while maintaining all the key features of Windows, Windows CE provides steady and

reliable real-time performances.

The Operating System can grow by adopting the “Dual Operating System”

conguration that allows Windows CE and Windows "desktop" to run in parallel on the

same hardware platform giving both the advantage offered by Windows CE for the

real-time features and by Windows "desktop" able to run sophisticated HMI software

and business applications.

Each hardware and O.S. configuration can be combined with three main predefined

functional levels of software where the building blocks are pre-configured to

implement different solutions and applications, from General Motion Control to CNC

for 3D machining. Each configuration can than grow adding further features.

OPEN-10

PLC/GMC (General Motion Control). It is a powerful control software conguration that

can handle up to 64 axes, through 40 interpolators each managing 12 simultaneous

axes. It is a solution dedicated to General Motion Control applications where the IEC

61131-3 programming is used together with a rich Motion Control functions library.

OPEN-20

CNC solution dedicated to 2D machining centres. It’s a software conguration for

Numerical Control able to run up to 24 independent parallel programs using ISO G-code

programming (EIA RS274 programming language extended with powerful custom OSAI

functions). Each program can interpolate up to 12 simultaneous axes out of a total of

64 axes that may be congured and used in different processes (channels).

OPEN-30

CNC solution dedicated to 3D machining centres. Same as OPEN-20, but specically

designed to manage machine tools with different type of spindle head (double twist,

prismatic or generic) where Tool Centre Point, Spline functionality, plane rotations

and axes virtualization are required.

OPEN - 10

OPEN - 20

OPEN - 30

OPENcontrol Technical overview

5

The embedded SoftPLC

All OPENcontrol units include a

powerful SoftPLC fully integrated with

the system and sharing the hardware

resources. The real-time multi-

tasking SoftPLC is programmed using

“4Control”, a graphical environment

based on IEC 61131-3, to develop

the machine logic using standard

languages (IL, LD, ST, FB, SFC).

The tool includes debugging functions

such as break points, tracing,

viewing of variables using point &

click operation and utilities such as

modications “on the y” and “warm start” of logic that speed up the commissioning of

the machine.

The organization of the integrated real-time machine logic environment permits the

execution of up to 250 parallel tasks, with 10 different levels of priority and cyclical

scheduling time that can be as fast as 250 microSec.

The M, S, T functions from Part Program, motion acknowledgment, console commands

and generally all the asynchronous system requests are communicated to the PLC by

event tasks. The fast execution, respecting the required priority, reduces the execution

time of the part program which increases machine productivity.

The OPENcontrol PLC allows the creation of real application programs that interact with

the system at all levels:

Data Exchange and synchronization with the HMI and with the processes managing

the part-program execution

Tool and Offset management

Axes motion from logic (point to point, interpolated, start/stop on event, master/

slave, CAM)

Sharing and motion of Coordinated Axes (axes used for ISO program execution)

Interaction with Coordinated Axes interpolators

Management of peripherals and data files in text, binary or XML format

Communication with other devices through local network.

An extensive library of more than 400 functions allows effective control of the whole

system and the ability to modify its standard behaviour to adapt it dynamically to the

application requirements.

6

Standard ready-to-use Machine Logic

In order to accelerate machines commissioning, OSAI offers predened Standard Machine

Logics designed for specic application elds (laser, plasma and oxy-fuel cutting) or

general ones (wood or metal milling).

OSAI Standard Machine Logics contain all basic cycles required for machines management

in different application sectors and they are designed for an easy customization.

The pre-dened OSAI section is easy to use and to congure and it can be updated with

new versions without requiring any change of the user section. User section, instead,

can use all the exibility of the integrated PLC to develop special cycles and machine

customizations.

WinNBI

Due to the common characteristics of the various OPENcontrol family components, it

is possible to have a unique operator interface environment. The OSAI Graphical suite

WinNBI (Windows™ Network Based Interface) has several pre-congured video screen

pages and allows the creation of complex interfaces without requiring the user to write

application software. It allows the management of different languages, including those

using non-European fonts.

WinNBI is available in versions for both Windows desktop (Windows 10 and previous) and

for Windows CE. It can be used in all OPENcontrol congurations, whether with local

(OSAI Operator Panel, Monitor) or remote (networked PC, Portable Intelligent Console)

front-end. WinNBI can interconnect many CNCs on the LAN, screen layouts can integrate

data coming from all of the CNCs on the network, on independent pages or even on the

same page.

OPENcontrol Technical overview

7

WinNBI consists of different applications, each one with specic functionality:

End User toolkit Windows desktop Windows CE

BootController ● ● CNC boot manager

ProcessController ● ● CNC main and auxiliary screens manager and builder

SystemHistory ● ● System journal

TableEditor ● ● Table data manager (Offset, Tool, Origins…)

MachinePlot ●- 2D/3D graphical drawing of the tool trajectory

FileBrowser ● ● File manager (for CNC and PC)

PathView/ISOView -Graphical tool for Part Program preview and management

DigiCAD - 3D graphical tool for digitizing with Spline

OPENCut - CAM for Plasma & Laser Cutting

OPENMill Conversational 2D programming and mini-CAM for

milling/drilling machines

OEM toolkit

ODM ●-System congurator and run-time calibration

Security ●-SW Installation, backup, restore. License manager

Calibration Tool ● ● I/O mapping tool for an easy conguration of the I/O

TimeMonitor ●-PLC and System task timing graphical monitor

O-Scope ●- Oscilloscope to trace many system parameters

● Available Option - Not available

Process Controller

The application Process Controller, designed to display all the most important information

of the machine tool and to interact with the end-user, allows full customization of the

operator interface in a multi-screen environment using the Layout Builder tool.

Layout Builder offers a wide range of graphical “objects” to create custom screens using

only the mouse with a “Point & Click” and “Drag & Drop” approach, with no need of any

knowledge of programming languages. The single screen can be selected and activated

automatically (as and when events occur) or manually (by toggling real or virtual

buttons). Among the various objects available, there are programmable push buttons,

directly interfaced with CNC functions or managed by the machine logic, the display

and animation of graphic bitmap-objects, progress bars, data entry elds as well as CNC

messages, and variable displays and editing of variable values.

8

IsoView

IsoView is an advanced graphical object that can be integrated in any page of the Process

Controller. It is a panel which displays the complete part under machining (preview)

reading basic G-code commands in the selected part program. IsoView also outlines the

block in execution and shows the tool position on the prole with a pointer.

IsoView is also available as an independent application in the WinNBI suite.

Internationalization

The WinNBI manages different languages using les with Unicode format that allows the

use of non-European fonts. A built-in LayoutBuilder function provides a simple mechanism

for the translation of text used in the custom video layout, through export and import

of text les.

Connectivity

OPENcontrol and WinNBI allow complex distributed architectures. WinNBI can interconnect

many CNCs on the LAN, located in different areas of the factory or as part of a modular

machine. It can also be distributed on more than one PC, allowing the control of all CNCs

in the network from several nodes.

A new CNC communication method, based on cross platform Web Services (WSDL le and

SOAP protocol), has been developed in OPENcontrol to support such a exible, network

based, architecture. It has the same performances of the previous protocol (historically

based on COM/DCOM technology) with the advantage to allow development of the HMI in

different O.S. hosting the clients.

Custom Operator Interfaces

Complementing WinNBI or as an alternative to it, specic operator interface applications

or supervision systems can be developed using the channel based on Web Services

(easily managed by modern software Integrated Development Environments such as

VisualStudio, NetBeans, Eclipse). The applications can also be written in VB, C++, C#,

Java or other advanced languages, interfacing with the CNC through a simple to use DLL

library wrapping and hiding the Web Services communication method. The same library is

used for back compatibility, allowing legacy application, to continue working.

OPENcontrol for Metal Cutting and Milling

Thanks to its exibility, OPENcontrol system can be used in different markets,

such as laser, plasma and oxy-fuel cut and for chip removal machines. In order to

accelerate CNC installation and to reduce time-to-market of machines using specic

technologies, OSAI developed ready-to-go software solutions, each one dedicated to

a specic sector.

OPENcontrol Technical overview

9

Software products developed by OSAI, supported by pre-dened machine logic, designed

for specic application sectors, simplify both commissioning and machine use, adding

high-level performances.

In addition to the WinNBI graphical suite, OPENcontrol can be supplied with:

OPENCut Plasma, for Plasma and Oxy-fuel cutting machines

OPENCut Laser, for Laser cutting machines

OPENMill, for Machining Centres

OPENCut - Plasma and Oxyfuel cutting

OPENCut Plasma is an advanced HMI and CAM software that manages both the execution

of programs generated by CAD and the parametric and local graphic programming through

predened on-board proles which do not require any knowledge of ISO language.

OPENCut also manages the technological tables, allowing the change of cutting parameters

on board, with no change of the cutting CAD program.

On-board cutting technology database.

HMI Plasma cutting section is complete and easy to use.

10

OPENCut CAM increases according to user requirements, from 2D cutting and manual

nesting, up to completely automatic Bevel applications. As typical for the whole OSAI

product range, software is designed in combinable modules.

Library with predened 2D parts.

Easy conversational programming based only on graphical elements

and geometric data.

True shape nesting of different parts. Automatic denition of cutting parameters.

Automatic lead-in/lead-out placement.

OPENcontrol Technical overview

11

Graphic preview of the Prole and dynamic display of the torch position and path.

3D realistic simulator

OPENCut CAM also includes:

DXF and DWG files import

Double torch management (Plasma) and multiple torch management (Oxy)

Drilling heads management

Restart and automatic or manual repositioning after and interruption

Torch collision detection

Manual cut

Cutting path check and correction of the collisions

Cycle-time calculation

Bevel cutting management

The machine logic designed for Plasma and Oxy-fuel cutting machines is exible, scalable

and perfectly coordinated with the integrated OPENCut software and allows the rapid

application of the CNC. Functions such as the automatic control of the torch height,

the dynamic regulation of the Plasma power according to the speed and the automatic

management of cutting tables with exhaust ventilation system sectors are available.

12

OPENCut - Laser cutting

OPENCut Laser shares with OPENCut Plasma all the basic functions for metal sheet cutting

and includes many advanced functions for Laser machining:

Laser Source

Support of the most common laser sources

Laser power control with dedicated

hardware for PWM

Modulation of beam-on signal

Fast control of laser (μs)

Gas Management

N2, O2, High pressure N2and air control

Automatic pressure control using existing pressure feedback signals

Various functions to maintain stable gas supply

Tolerance check

Heights Control

Supports the most common cutting heads on the market

Metal sheets loading system

Support of various sheet loading systems and magazines

Machine Functions

Technological database on board

Marking

Film burning

Various piercing mode

Micro-joint along X and Y direction

High Speed cut without piercing

Multi-line cutting

Automatic and manual plate angle determination

Recipes of NC jobs

Restart methods:

• Backward on the contour and restart

• Manual motion of the axes and restart

• Restart from selected icon/profile

Selectable dynamics per jobs

Change of cutting parameters on the fly

Configurable diagnostics and maintenance with custom pages

Automatic selection of technology

OPENcontrol Technical overview

13

OPENMill - Millling machines software

OPENMill software is an intuitive environment for programming and management of

milling/drilling machines. It manages the execution of programs dened by a local graphic

and parametric programming and it includes a conversational editor, characterized

by extreme ease of use, allowing several

predened cycles besides the denition of

proles on the plane through geometrical

graphical elements. OPENMill is also the

new OSAI HMI interface dedicated to milling.

The end-user environment, specically

designed to expedite CNC use, requires few

commands, from soft-keys or touch-screen, to

use the main functions of the CNC. It includes

an integrated graphics with part preview for

program selection and real-time graphics to

highlight the parts being processed.

By using the pre-dened cycles, the operator is only required to select the desired cycle

and to insert the geometrical parameters, as shown below:

Selection of the preset cycle. Setting of the geometrical parameters.

Drilling and tapping cycles. Slot milling.

14

Bossing. Facing.

Similarly, OPENMill allows the rapid block to block graphic denition of contouring and

milling proles.

Selection of geometrical element. Generated prole display.

An ambient specically designed for technology, allows the setting of tool parameters

and machine origins.

Technological data table. Import functions of DXF les generated

by CAD increase the operating

possibilities of OPENMill.

OPENcontrol Technical overview

15

Axes Management

Coordinated, Auxiliary, Pseudo and Spindle axes

The OPENcontrol CNC can manage different kinds of axes:

Coordinated Axes (or Process axes) moved by the Operator via manual or

programmed movements. They are managed by the Process Interpolator.

Auxiliary Axes moved by the Machine Logic and managed by a number of Auxiliary

Interpolators that have the same characteristics and potentiality of the coordinated

axes interpolator.

Pseudo Axes. They are used to send information from the part program to the

machine logic.

Spindle axes are those to which tools are normally fitted. They are controlled

by the Machine Logic and managed by a specific Interpolator. One spindle can be

configured for each process and hence up to 24 spindles. Moreover, it is possible to

share or exchange spindles between processes

With the CNC systems up to 12 axes (12 coordinated axes, 6 pseudo axes) can be

programmed in the same part program block. The Machine Logic can manage up to 40

interpolators with dynamic axes conguration. Also in this case, up to 12 axes can be

interpolated by each interpolator.

Linear and Rotary Axes

Both coordinated and auxiliary axes can be declared as linear (programmed in mm or

inches) or rotary (programmed in degrees).

Rollover Axes

Linear or rotary axes whose position is always displayed in the range from zero to a

maximum congurable positive value (“rollover pitch”). These axes can be programmed

either in absolute or incremental mode.

Diameter Axes

For a diameter axis, the programmed position is twice the actual movement. This

programming mode is typically used in cylindrical geometry machines (lathes or grinding

machines).

Dual Axes (UDA, SDA)

Dual axes are two or more physical axes that follow an identical path (typically in Multi-

head machines). One is the "master" programmed by the Machine Operator, while the

others are "slaves" commanded by the system to follow the master movements (directly

or in mirror mode).

The link between master and slaves is enabled or disabled by the part program. It is

possible to program up to 6 master axes and up to 17 slave axes for each master.

Software Key Features

16

Master/Slave axes (XDA)

This feature has the same functions of UDA and SDA instructions, but allows the

denition of following mode slave/master. In fact, following parameters (ratio -

higher, equal or minor than 1.0) and mode can be dened for each slave.

The feature is also available in the PLC, making it possible to link a slave, without stopping

the master, when an event detected by the machine logic occurs.

Dynamic follower axes (AXF)

Moves along the programmed path, but independently without affecting the velocity

of the other coordinated axes. These axes follow the axes dening the prole without

changing or limiting their dynamic capabilities.

This avoids, for example, the velocity dropping

to zero in the positions where the follower axes

start or stop their motion.

Gantry Axes (Split)

A gantry axis is a physical axis having only one

interpolator and two motors. They are managed

by the Operator and programmed as one axis.

Gantry Axes (X and Z)

Axes Motion

Linear, Circular, Circular 3D, Helical, Helical 3D and Spline

interpolation

OPENcontrol manages:

Up to 12 axes in Linear interpolation.

Up to 2 (3 for 3D circles) axes in Circular interpolation.

Up to 12 axes in helical interpolation: 2 (3 for 3D circles) of these perform a Circular

interpolation, the others a Linear interpolation.

Circular and helical 3D interpolation allow the proles execution in the space with no

rotation of the reference interpolation plane.

Spline algorithm, which can be enabled for the execution of previous linear and circular

blocks, allows to increase the speed on the programmed prole, reducing machining

times. A polynomial curve built on the circular and linear points, describes the trajectory

to follow. This trajectory will pass through the programmed points towards the set

thresholds.

OPENcontrol Technical overview

17

Tool Radius Compensation

OPENcontrol automatically applies the tool radius compensation calculating the axes

trajectory needed for machining the path described in the part program. This functionality

(enabled by G41, G42 codes) can be instructed to compensate either the tool radius or

the tool thickness. The Tool Compensation can also be applied in the space (3D) either

through the Paraxial Compensation (compensation factors u,v,w) or through versors

(m,n,o and p,q,d) when TCP (Tool Center Point) is active.

Tool radius compensation on a circular motion. Application of the tool

compensations through versors.

Motion Modality (accel and decel RAMP parameters)

OPENcontrol makes a sophisticated interpolation algorithm available that controls the

axes acceleration/deceleration phases on the basis of the dynamic requirements of

the machine. Acceleration and deceleration are also independent and can be set with

different parameters. OPENcontrol manages:

Linear Ramp

S Ramp

Trapezoidal Ramp

S Ramp with Jerk limitation

Point to Point and Continuous Mode with Look Ahead

In point to point mode (G29) OPENcontrol executes the programmed movements stopping the

axes at the end of each move. In continuous mode (G28) the system executes all movements

at the programmed feedrate, without stopping the axes at the end of each move.

The G28 continuous movement follows the prole at high speed, but can cause overshoots

on the edges or during inversion of the axes. For this reason another type of continuous

motion (G27) is available. It “foresees” the dynamics of the motion of the axes along

the path (up to 1024 Look Ahead blocks) and adapts the speed of the tool accordingly, so

that the output velocity from the individual blocks dening the trajectory is optimized.

The narrower the angle between two successive blocks is, the more the speed is reduced,

going to zero if a preset threshold is exceeded.

OPENcontrol has new automatic high performance algorithms for determining the speed

of the axes in the transition from one block to the next in G27 mode.

Software Key Features

18

Table of contents

Popular Control System manuals by other brands

Ampcontrol

Ampcontrol iMAC2 user manual

ABB

ABB 620 Series ANSI installation manual

Systemline

Systemline 4.4 Installer manual

Bulk Man 3D

Bulk Man 3D OX CNC Mechanical Assembly Instructions

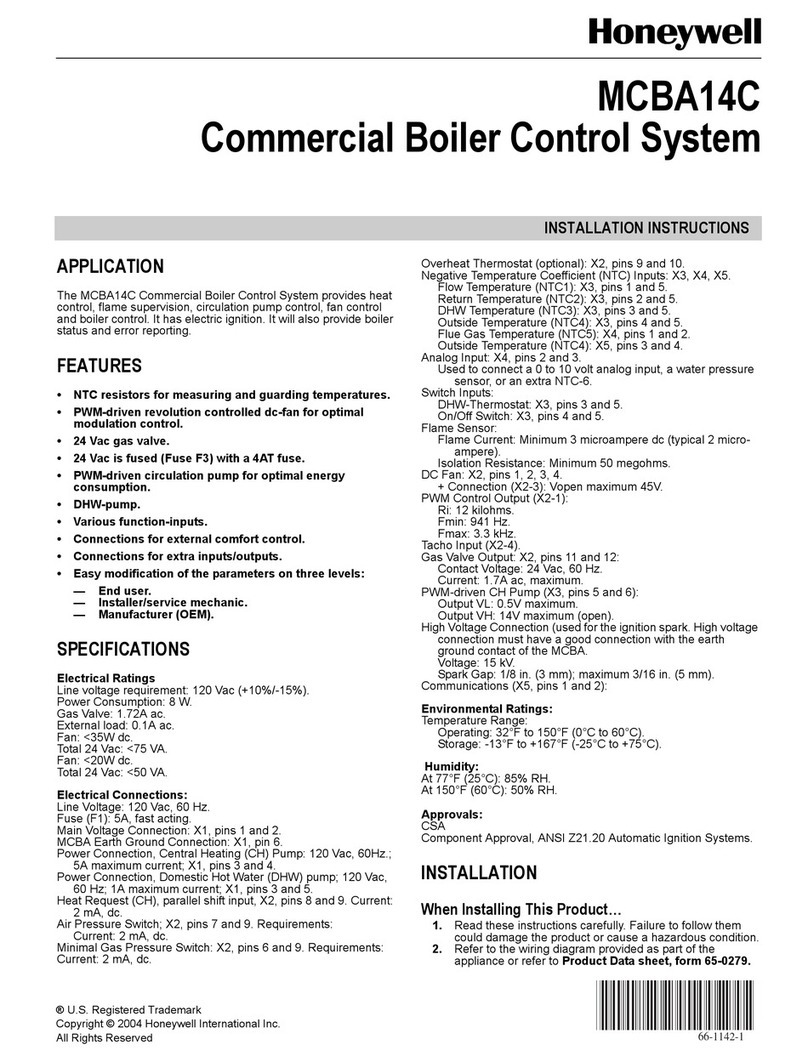

Honeywell

Honeywell MCBA14C Installation instructions manual

Buderus

Buderus Logamatic 2107 Installation and service instructions