EVCO | 21.10.2020 | AZ | 8

008_EVLJBOX_Sequencer_Installazione_001_0.1_AZ

008_EVLJBOX_Sequencer_Installazione-02_001_0.1_AZ

008_EVLJBOX_Sequencer_Installazione-02_001_0.1_AZ

c-pro 3 OEM

144EJBSI104

EVLJBOX HP Sequencer - Application manual

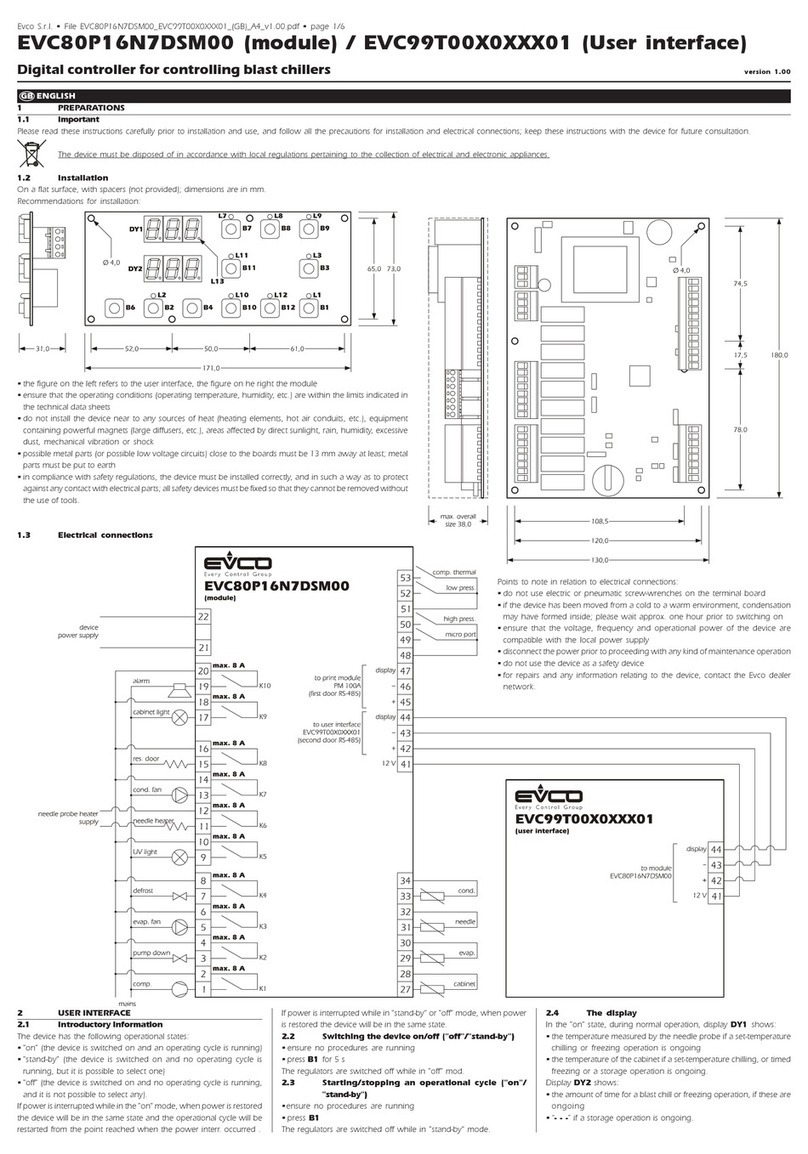

Installation

INSTALLATION PRECAUTIONS

–Ensure that the working conditions are within the limits stated in the “Technical specications” section.

–Do not install the device close to heat sources, equipment with a strong magnetic eld, in places subject to direct

sunlight, rain, damp, excessive dust, mechanical vibrations or shocks.

–In compliance with safety regulations, the device must be installed properly to ensure adequate protection from

contact with electrical parts. All protective parts must be xed in such a way as to need the aid of a tool to remove

them.

–Users will need a rigid pipe tting; the maximum diameter of the xing hole must be 28.5 mm

–To ensure IP65-rated protection of the whole casing, x the container using only the holes already made

Wall mounting

1. Secure the back cover |7| to the wall using the 4 screws

|1|

and the holes already made |6|

2. Make sure the seal |8| is correctly inserted

3. Place the front cover |4| over the back cover

|7| and push the 2 assembling tongues |10|

down into the holes |2| on the right or left

of the front cover |4|

4. Fix the user interface |12| into place by pressing it

into its housing |5| from the front

5. Fix the control module |14| to the DIN rail |16|;

next secure the DIN rail |16| to the back cover

|7| in its housing |17| with two screws |15|

6. If the connection cables are fed in from above,

make a hole whose diameter is suitable for xing

a rigid pipe tting |13| on the top of the

back cover |7|; if the cables are fed in from the

bottom, make the hole on the bottom of the cover

7. Screw the rigid pipe tting |13| to the back

cover |7|

8. Connect the user interface |12| as shown in the

section “Electrical connections”, feeding the

connection cables through the rigid pipe tting |13|

9. Secure the front cover |4| to the back cover |7|

using the 4 screws |9| and the holes already made |3|

10. Fix the covering strips |11| over the top and bottom

parts of the front cover |4|

74

5

1

9 13

1514 16

17

17

10 11 12

2 6 8

3