Table of Contents

1 General Information...................................................................................................3

1.1 Scope of these instructions........................................................................................3

1.2 Designated use........................................................................................................... 3

2 Safety instructions......................................................................................................4

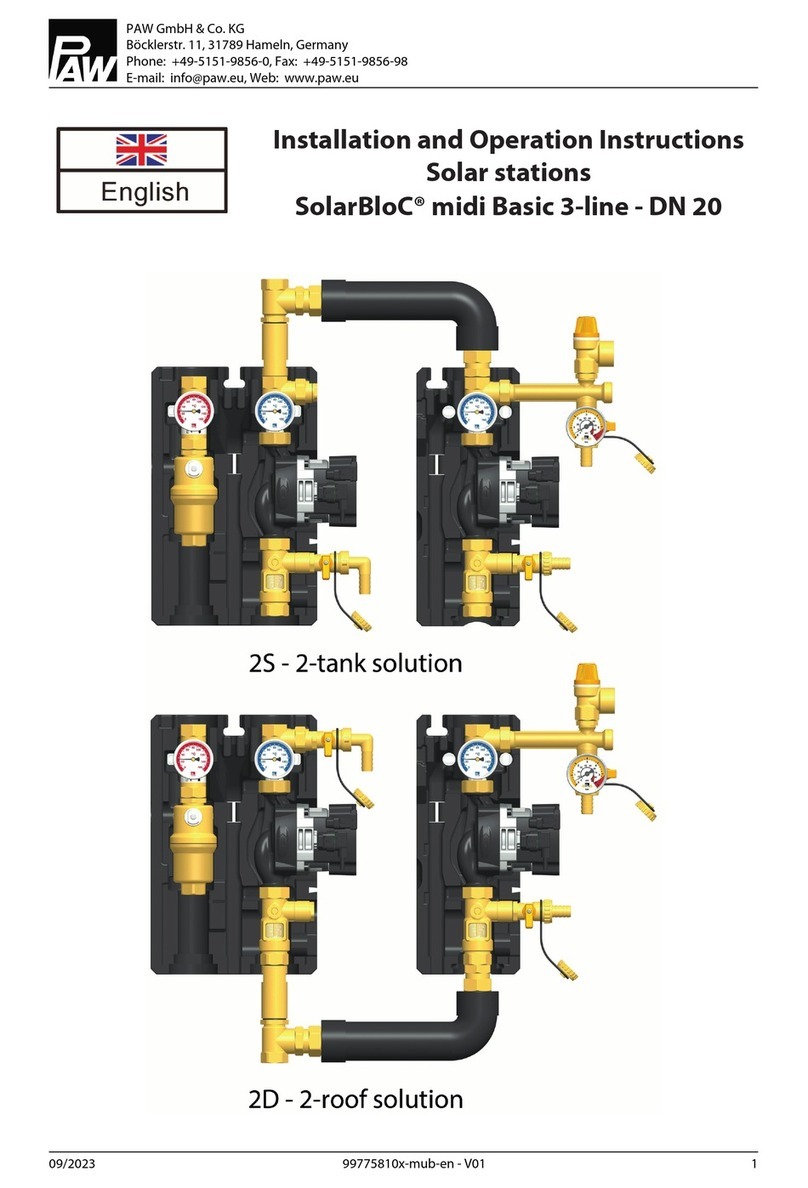

3 Product description.................................................................................................... 5

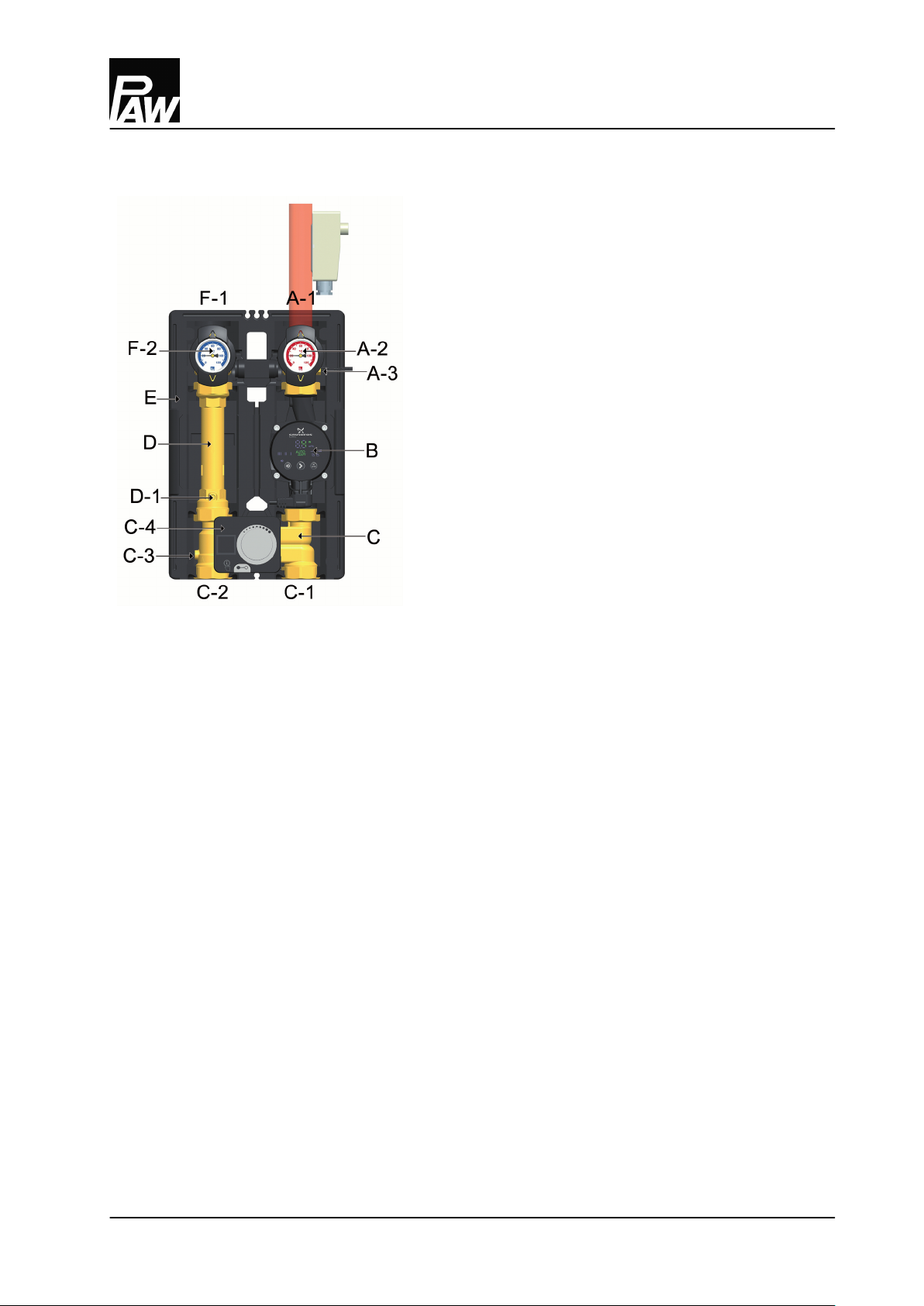

3.1 Equipment...................................................................................................................6

3.2 Function.......................................................................................................................7

3.2.1 Check valve and non-return valve.............................................................................8

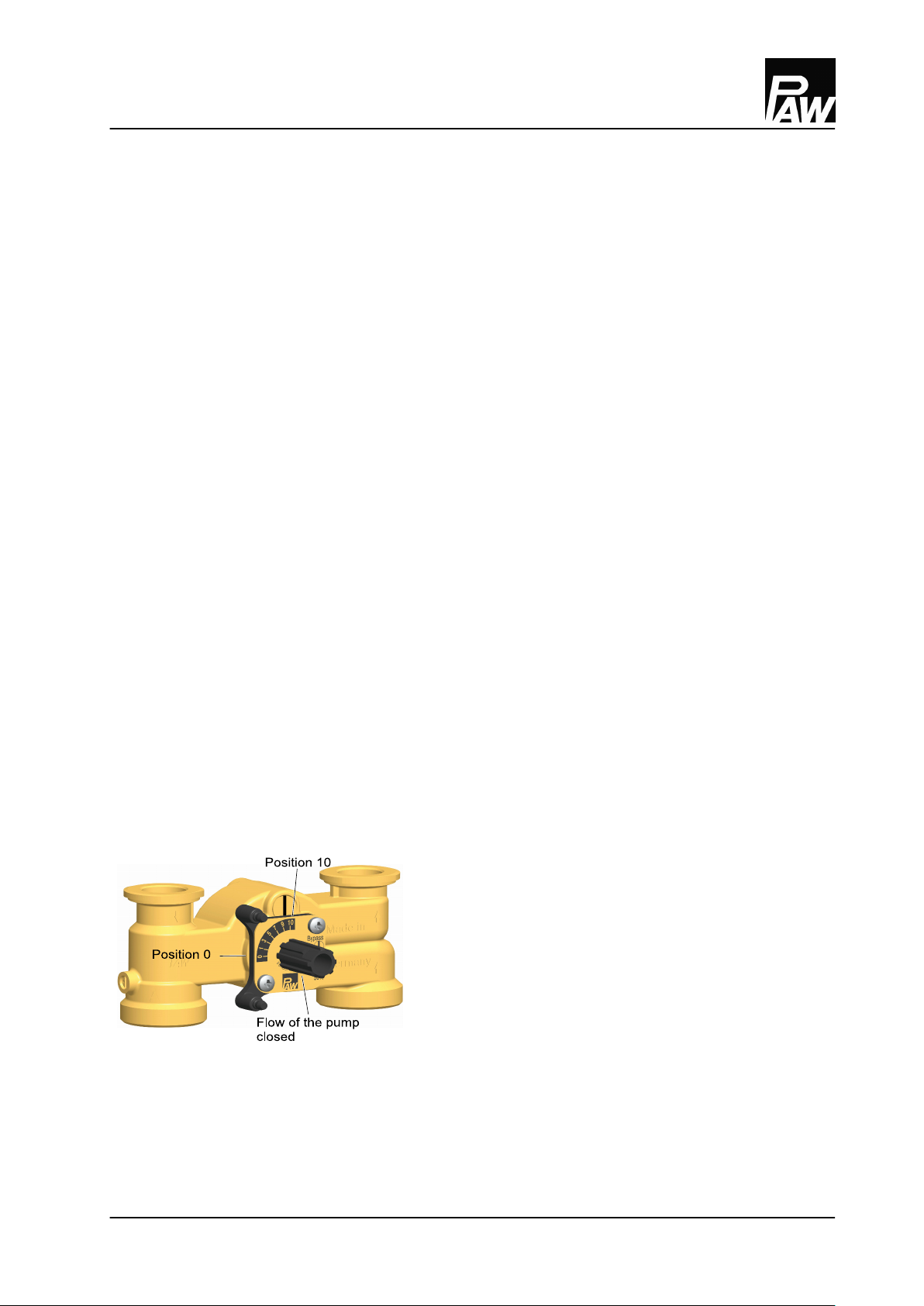

3.2.2 Pump [specialist].........................................................................................................9

3.2.3 3-way mixing valve [specialist]..................................................................................9

3.2.4 Change of the flow line [specialist]........................................................................... 10

3.3 Constant temperature controller PKR6.................................................................... 13

3.4 Setting of the constant temperature controller PKR6 as a return flow

temperature maintenance.........................................................................................13

4 Mounting and installation [specialist]...................................................................... 15

4.1 Installation and commissioning of the HeatBloC®...................................................15

4.2 Accessories: Cutting-ring compression fitting (not included in the scope of

delivery).......................................................................................................................18

5 Scope of delivery [specialist]..................................................................................... 19

5.1 Spare parts DN 25....................................................................................................... 19

5.2 Spare parts DN 32....................................................................................................... 21

6 Technical data............................................................................................................. 23

6.1 Pressure drop and pump characteristic curves DN 25.............................................25

6.2 Pressure drop and pump characteristic curves DN 32.............................................25

7 Disposal....................................................................................................................... 26

Table of Contents

07/2023 993x0463x-mub-en - V03 2