B614 1 532297 - Rev.D

CONTENTS

1. IMPORTANT SAFETY INFORMATION .................. 3

UL325 Gate Operator Classifications..................... 5

Introduction to this instructions manual................. 6

Transport and storage .................................. 7

Unpacking and handling................................ 8

Disposal of the product................................. 8

2. B614 .................................................. 9

2.1 Intended use......................................... 9

2.2 Limitations of use .................................... 9

2.3 Unauthorised use .................................... 9

2.4 Emergency use...................................... 10

2.5 Manual operation ................................... 10

Release procedure .................................... 10

Restore normal operation ............................. 10

2.6 Product identification................................ 11

2.7 Technical specifications .............................. 11

2.8 Component identification ............................ 12

2.9 Installation components ............................. 13

2.10 Optional accessories................................ 13

3. INSTALLATION REQUIREMENTS...................... 14

3.1 Mechanical requirements ............................ 14

3.2 Electrical system .................................... 15

3.3 Example system..................................... 16

4. MECHANICAL INSTALLATION......................... 17

4.1 Tools required ....................................... 17

4.2 Installing the foundation plate ....................... 18

4.3 Installing the barrier body ........................... 19

Rounting the cables inside the barrier .................. 20

4.4 Installing the arm ................................... 21

Preparing the rocker arm .............................. 21

Installation ........................................... 21

4.5 Mounting the spring................................. 23

Turnbuckle ........................................... 23

Single spring.......................................... 24

Double spring......................................... 24

4.6 Accessories on the arm............................... 25

4.7 Balancing the arm................................... 25

4.8 Limits adjustment................................... 26

4.9 Grounding the door ................................. 27

4.10 Closing the door ................................... 27

4.11 Installing the top cover ............................. 28

5. ELECTRONIC INSTALLATION.......................... 29

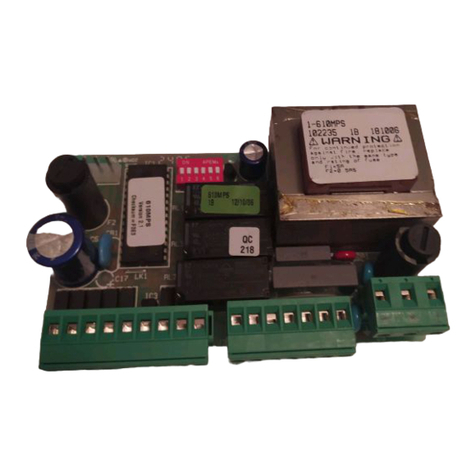

5.1 Board E614 ......................................... 29

Components ......................................... 29

5.2 Connections ........................................ 31

Control devices ....................................... 31

External loops ........................................ 32

BUS devices........................................... 32

OUT outputs .......................................... 32

24 V "flashing light ................................. 32

Motor ................................................ 32

Encoder .............................................. 32

Arm lights ............................................ 33

Integrated flashing light............................... 33

XF radio module ...................................... 33

Mains supply and earthing............................. 33

6. START-UP ............................................ 34

6.1 Programming ....................................... 34

Basic programming ................................... 34

Advanced programming .............................. 35

6.2 Operating logics..................................... 38

EP - Semi-automatic step by step ..................... 38

A- Automatic......................................... 38

AP - Automatic step-by-step.......................... 38

b- Semi-automatic b ................................. 38

bC- Semiautomatic bon opening/ person present Con

closing ............................................... 38

C- Dead-man ........................................ 38

P- Parking ........................................... 38

PA - Parking Automatic ............................... 38

6.3 SET-UP ............................................. 39

7. PUTTING INTO SERVICE .............................. 40

7.1 Final checks......................................... 40

7.2 Final operations ..................................... 40

Field installed labels .................................. 40

8. ACCESSORIES......................................... 41

8.1 24V

"flashing light ................................ 41

8.2 XF radio module..................................... 41

Deleting radio controls from memory .................. 42

LC/RC - Remote code STORING procedure ............... 42

8.3 BUS 2easy devices................................... 43

Connection ........................................... 43

BUS 2easy photocells .................................. 43

Control devices ....................................... 43

BUS 2easy device registration.......................... 44

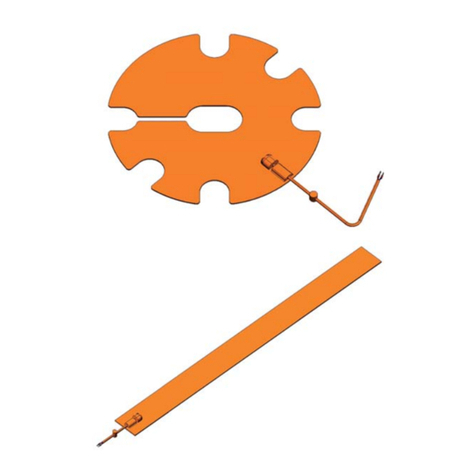

8.4 Rectangular arm light kit ............................ 45

8.5 Integrated flashing light ............................. 45

8.6 Articulated arm kit .................................. 45

8.7 Skirt................................................ 46