OSAKA –SMART BOX –Simple Manual –v1.1 –Page 4

8 –ALARMS__________________________________ _

8.1 Alarms_______________________________ _______

Minimum temperature alarm

Maximum temperature alarm

High pressure switch alarm

Low pressure switch alarm

Thermal compressor 2 alarm

Condenser overheating alarm

Defrosting finished due to max. time alarm

Alarm of boost pump controlled through the

digital input, finished due to maximum time

9 –ERRORS______________________________ ______

9.1 Errors____________________________________ __

Room temperature probe error or air input

temperature probe error (according to the P4

parameter).

SD card without storage room

SD card not inserted/unrecognized

Data logger’s battery error

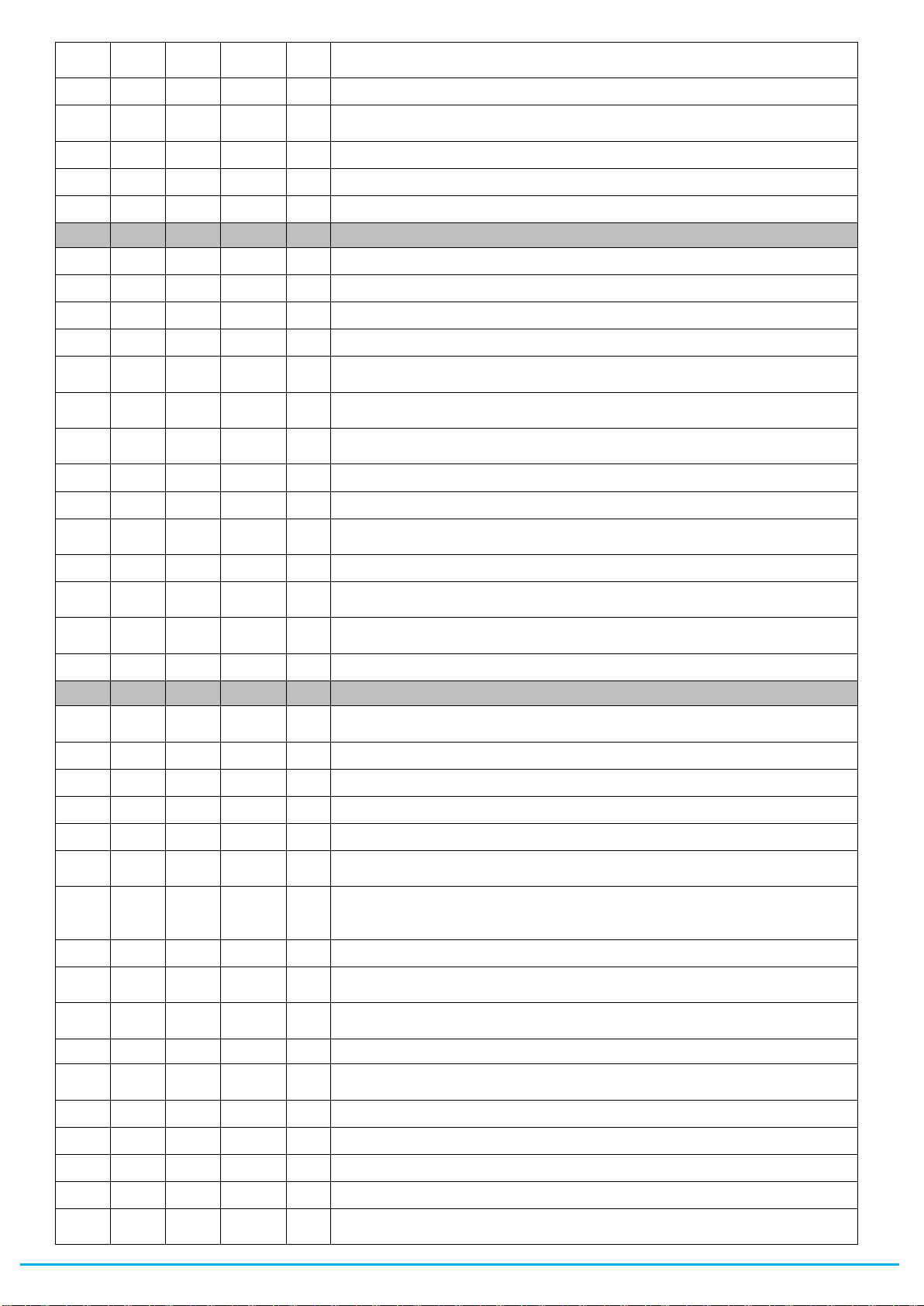

10 –TECHNICAL DATA_____________________ _____

10.1 Technical data___________________ ___________

Device’s function: Control device.

Device’s construction: Incorporated electronic device.

Case: Self-extinguishing, grey.

Heat and fire resistance category: D

Dimensions: 262,0 x 179,0 x 95,6 mm (10,314 x 7,047 x

3,763 in; W x H x D).

Mounting method: wall mounting, with anchor and fixing

screws.

Protection degree: IP65.

Connection: Fixed connection terminals with 6,35mm

(0,25mm) pitch for conductors of up to 4mm² (0,0062 in²):

power supply and digital outputs.

-Fixed connection terminals, pitch on thread of 5,0 mm

(0,196 in) for conductors of up to 2,5 mm² (0,0038 in²):

analog and digital inputs, and RS485 MODBUS port

-Removable terminal block (only male thread), 3,5 mm

(0,137 in) pitch for conductors of up to 1,5 mm² (0,0028 in²)

or JST connector (only male thread) with 6 pole-connectors

of 2,5 mm (0,098 in) pitch: controller for unipolar stepper

electronic expansion valves.

The maximum length of the connection cables are:

-Supply: 100m (328ft).

- Analog inputs: 100 m (328 ft).

- Transducers Power Supply: 100 m (328 ft).

- Digital inputs: 100 m (328 ft).

- Digital outputs: 100 m (328 ft).

- RS-485 MODBUS port: 1.000 m (3.280 ft);

- Controller for unipolar stepper electronic expansion valves:

3 m (9,842 ft).

Use cables of a section suitable to the flowing current.

In case of using the device fully charged and at a maximum

working temperature, use cables with a maximum working

temperature of ≥90 ºC (194 °F).

Working temperature:

-From 0 to 45 °C (from 32 to 113 °F) for the units with a

circuit breaker, with a differential circuit breaker.

-Otherwise, from 0 to 50 °C (from 32 to 122 °F).

Storage temperature: from -25 to 70°C (from -13 to 158°F).

Working humidity: from 10 to 90% of relative humidity

without condensation.

Contamination degree of the control device: 2.

Environmental compliance:

- RoHS 2011/65/CE

- WEEE 2012/19/EU

- REACH (CE) n° 1907/2006 Norm.

EMC compliance:

- EN 60730-1

- IEC 60730-1.

Supply: 115... 230 VAC (+10 %, -15 %), 50... 60 Hz (±3 Hz),

35 VA max., supplied by a class 2 circuit. The maximum

current allowed for the phase is 16A.

Circuit Breaker: Depending on which model [230 VAC, at

16A, Icn 4.500 A, unipolar + neutral, for conductors of up to

2,5 mm² (0,0387 in²)].

Differential Circuit Breaker: Depending on which model

[230 VAC, at 16A, Icn 4.500 A, Id 300mA, unipolar + neutral,

for conductors of up to 2,5 mm² (0,0387 in²)].

Type of ground connection of the control device: With

ground terminal.

Nominal pulse voltage: 4KV

Surge category: III.

Software’s class and structure: A.

Real Time Clock: Incorporated (with a secondary lithium

battery; only available in the SMART BOX SD and SMART

BOX PLUS SD models).

Battery’s life span without a power supply: 6 months.

Deviation: ≤ 30 s/month at 25 °C (77 °F).

Data logger’s battery: Incorporated (with a secondary

nickel-metal hydride battery; only available in the units with

data logging in compliance with the EN 12830 norm)

Battery’s life span without a power supply: 72 h.

Battery’s charging time: 24 h (the battery is charged with the

device’s power supply).

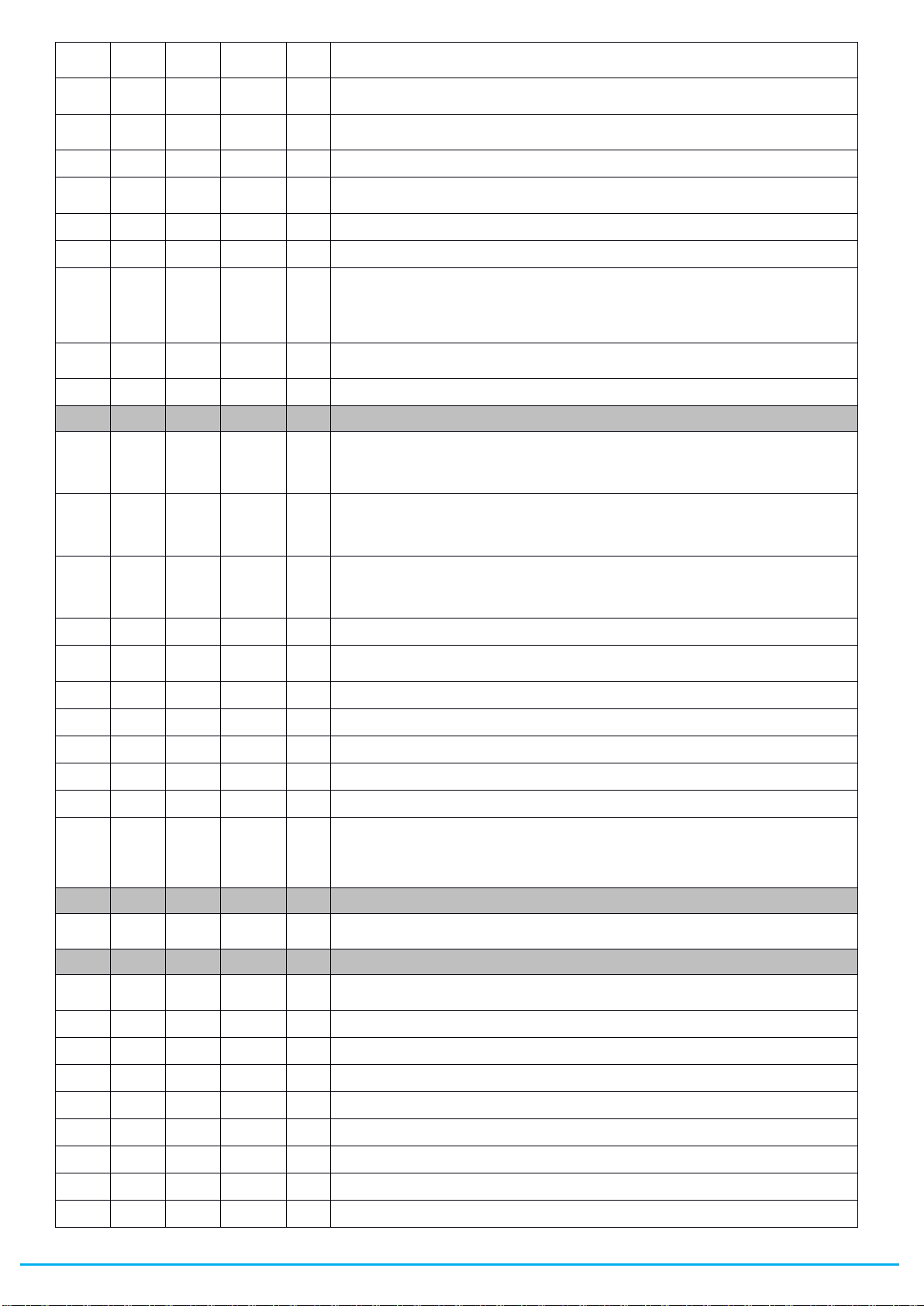

Analog inputs: up to 5 inputs:

- 2 that can be configured by parameter for PTC, NTC or Pt

1000 probes (room temperature or evaporator’s temperature)

- 1 that can be configured by parameter for PTC, NTC or Pt

1000 probes (it can be configured by parameter for

condenser).

- 1 that can be configured by parameter for PTC, NTC or Pt

1000 probes (evaporation’s temperature; only available in

the SMART BOX VEX).

- 2 that can be configured by parameter for NTC or Pt 1000

probes (auxiliary 2 and auxiliary 3 temperature; only

available in the units with data logging in compliance with the

EN 12830 norm).

- 1 for 4-20 mA transducers (low pressure; only available in

the SMART BOX VEX).

Transducer’s 4-20 mA supply: 12 VDC (±10 %), 30 mA max.

PTC analog inputs (990 Ω @ 25 °C, 77 °F)

Sensor type: KTY 81-121.

Working range: from -50 to 150 ºC (from -58 to 302 ºF).

Accuracy: ±0.5 % of the full-scale.

Resolution: 0.1 ºC (1 ºF).

Protection: None.

NTC analog inputs (10 KΩ @ 25 °C, 77 °F)

Sensor type: ß3435

Working range: from -50 to 120 ºC (from -58 to 248 ºF).

Accuracy: ±0.5 % of the full-scale.

Resolution: 0.1 ºC (1 ºF).

Protection: None.